Chicago Electric 66619 User Manual

Page 15

Page 15

For technical questions, please call 1-800-444-3353.

SKU 66619

Spark Plug Maintenance:

Disconnect Spark Plug Wire from end

1.

of plug. Clean out debris from around

Spark Plug.

Using the spark plug wrench provided,

2.

remove the Spark Plug.

Inspect the Spark Plug:

3.

If the electrode is oily, clean it using

a clean, dry rag. If the electrode has

deposits on it, polish it using emery

paper. If the white insulator is cracked

or chipped, the Spark Plug needs to be

replaced.

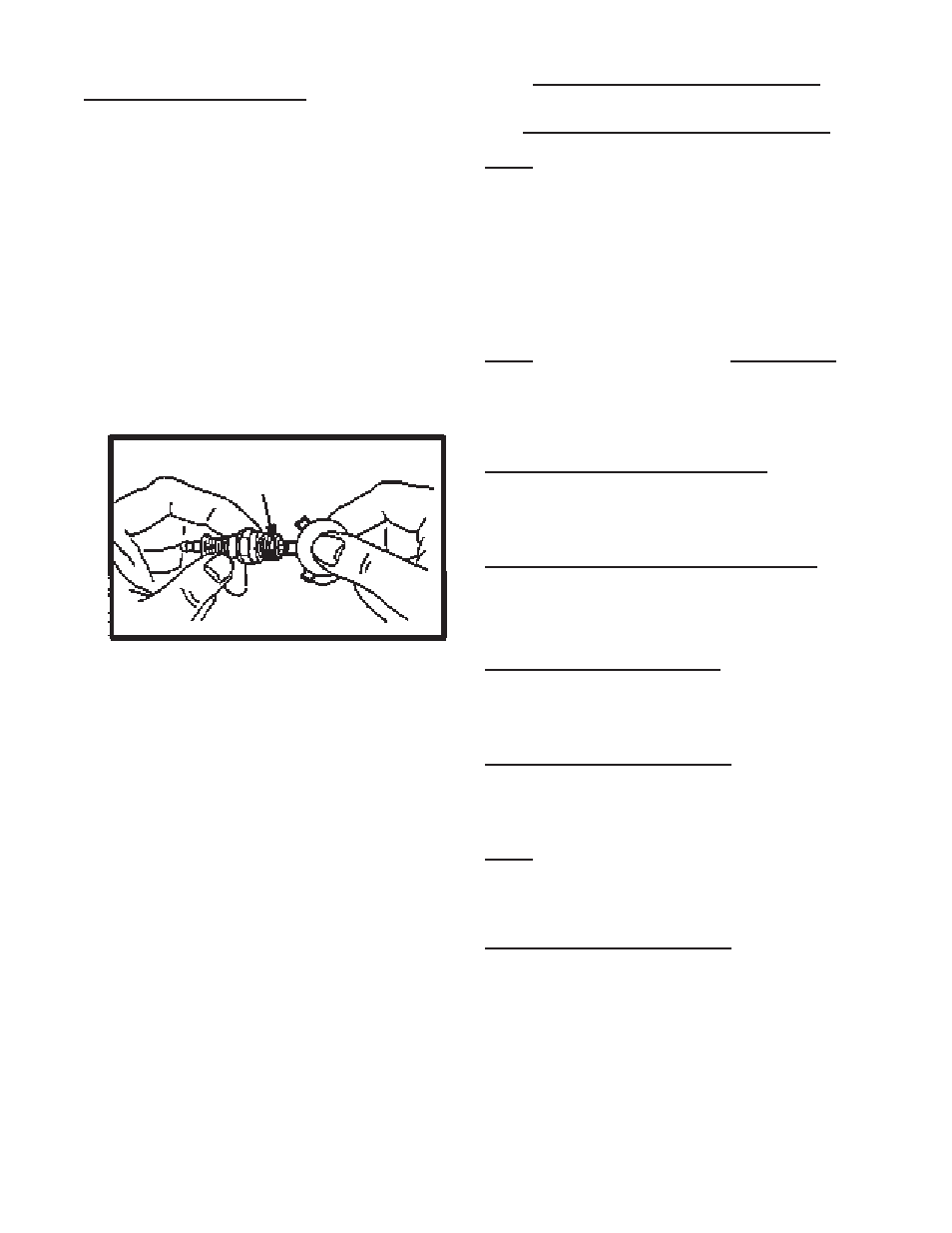

FIGURE o

0.028” ~ 0.031”

4. When installing a new Spark Plug, adjust

the Plug’s gap to the specification on the

Technical specification chart and in the

illustration below. Do not pry against the

electrode or the insulator, the Spark Plug

can be damaged.

(See Figure o.)

Install the new Spark Plug or the cleaned

5.

Spark Plug into the Engine. Gasket-

style: Finger-tighten until the gasket

contacts the cylinder head, then about

1/2-2/3 turn more.

Non-gasket-style: Finger-tighten until the

plug contacts the head, then about 1/16

turn more.

cleaning, Maintenance, and

lubrication Schedule: Engine

Note: This maintenance schedule is

intended solely as a general guide. If

performance decreases or if the Engine

operates unusually, check systems

immediately. The maintenance needs

of this Engine will differ depending on

factors such as temperature, air quality,

fuel quality, and other factors.

Note: These procedures are in addition to

the regular checks and maintenance

explained as part of the regular operation

of the Engine.

After Initial 25 operation hours:

Change unleaded gasoline and 2-cycle

a.

oil fuel mixture.

Every 25 operation hours Thereafter:

Clean/replace Air Filter Element.

a.

Inspect/clean Spark Plug.

b.

Every 50 operation hours:

Change unleaded gasoline and 2-cycle

a.

oil fuel mixture.

Every 100 operation hours:

Replace Spark Plug.

a.

Replace Air Filter Element.

b.

Note: All maintenance procedures scheduled

for 25, 50, and 100 operation hours

should be performed at least yearly.

Every 300 operation hours:

Clean Fuel Tank and Carburetor

a.

assembly.

Clean carbon build-up from Combustion

b.

Chamber.