Weller DS800 User Manual

Page 3

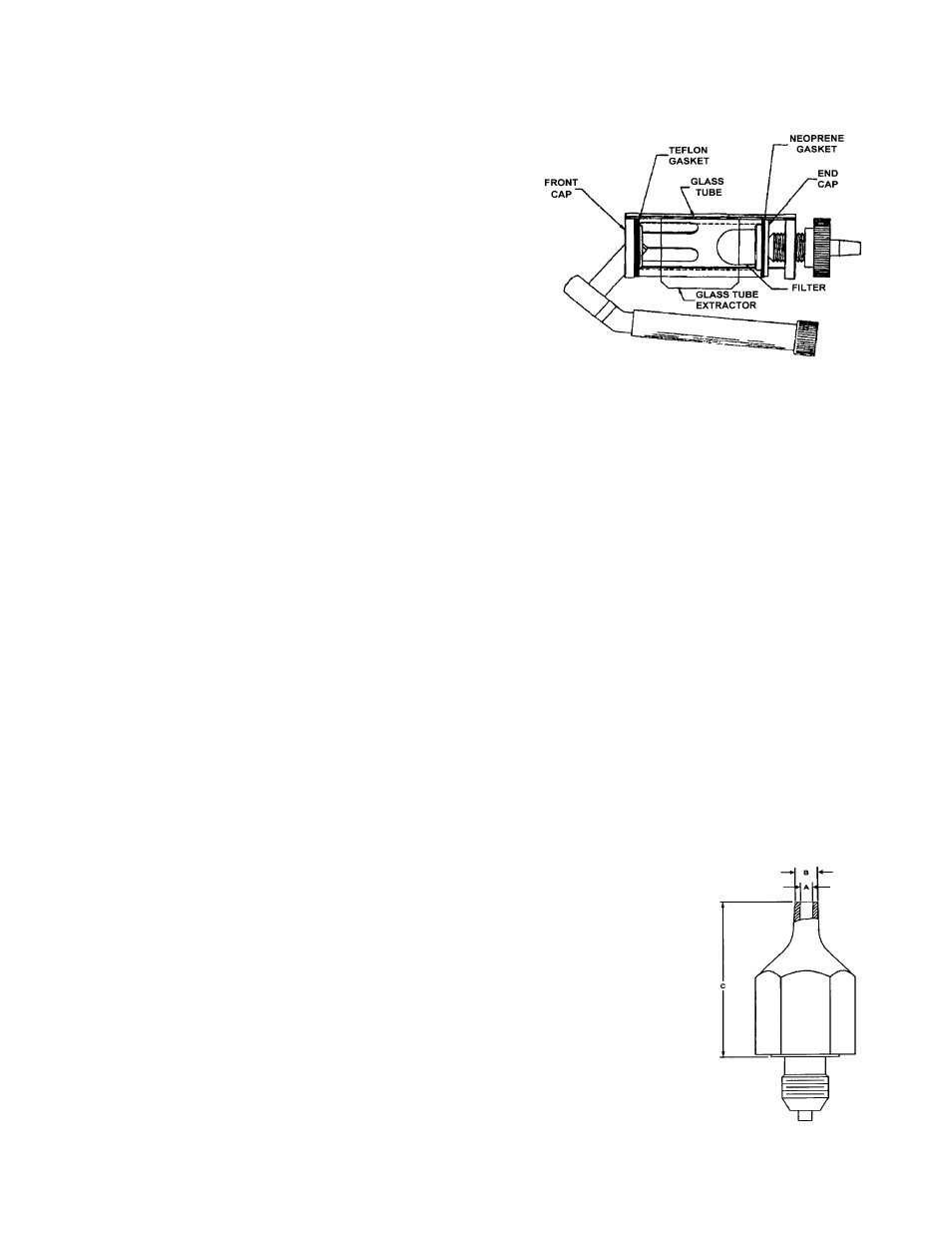

DSH219 DESOLDERING HEAD

Each desoldering iron has been provided with a cotton filter in the

collector tube. NEVER operate a desoldering iron without the filter in

place. The purpose of the filter is to prevent solder from entering and

clogging the vacuum tube or pump. Cotton has proven to be the best

material for this filter. See DS204 in parts list. Do not use spun

synthetic materials, such as rayon, because they will not withstand

the temperature in the desoldering head.

Each desoldering head is provided with two gaskets, a teflon sponge

gasket for the front of the collection tube and a neoprene rubber

gasket for the other end. The gaskets require periodic replacement

depending on use. Attempting to use the desoldering head without

both gaskets in place will cause a vacuum leak and result in poor

desoldering head performance.

POWER DESOLDERING HEAD

The glass collector tub should be handled with care. Remove the tube with the tube extractor provided. Allow the tube to cool

before attempting to clean and replace it into the head. Care should be taken to avoid dropping the tube onto the floor - it will

break. Do not tap the tube with pliers or a screwdriver, this might cause the edge of the tube to break.

Iron plated copper tiplets should be reamed out with the clean out tool approximately once every 15 minutes of operation.

Clogging may be experienced inside the stainless steel tiplet liner due to solder dross sticking to the liner preventive

maintenance with tiplets is important for trouble free desoldering.

VACUUM FILTER

The vacuum filter must be checked monthly for flux buildup. Flux fumes from desoldering will condense in the filter and slowly

restrict air flow. Access to the filter is from the bottom of the unit. The filter consists of a plastic foam element and a stainless

steel sponge pad. Both elements may be cleaned in alcohol or flux cleaner, dried and replaced.

TIPLETS FOR DESOLDERING TOOLS

The desoldering tiplets used on the DS1203 high mass desoldering tool are threaded designs. Thirteen sizes are available.

The DS800 comes with five high mass tiplets. There are also eight standard tiplets available. The high mass tiplets hold more

heat than the standard tiplets and can transfer more heat to handle heavy multi-layer P.C. boards. This makes desoldering

faster and there is less chance of burning the P.C. board. All tiplets are iron plated for good wettability and long life. Additional

plating of nickel and chrome are applied to protect the iron plating from oxidation and prevent solder from creeping up the

outside of the tiplet. All the desoldering tiplets useable with the DS1203 iron are shown in the next table.

AVAILABLE DESOLDERING TIPLETS FOR DS1203 IRON

STANDARD

DIMENSIONS

HIGH MASS

DIMENSIONS

TIPLETS A

B

C

TIPLETS A

B

C

DS110

.025

.060

.50

DSH110

.025

.060

.75

DS111

.025

.090

.50

DSH111

.025

.090

.75

DS112

.036

.076

.50

DSH112

.025

.076

.75

DS113

.045

.098

.50

DSH113

.045

.098

.75

DS114

.071

.125

.50

DSH114

.071

.125

.75

DS115

.025

.060

.75

DS116

.045

.098

.75

DS117

.025

.090

.75