5 parts list, 6 clean-up, 7 disassembly – Trebor SS95 Surge Suppressor User Manual

Page 9: Parts list, Clean-up, Disassembly

SS95 SURGE OPERATION / MAINTENANCE MANUAL

PAGE 9

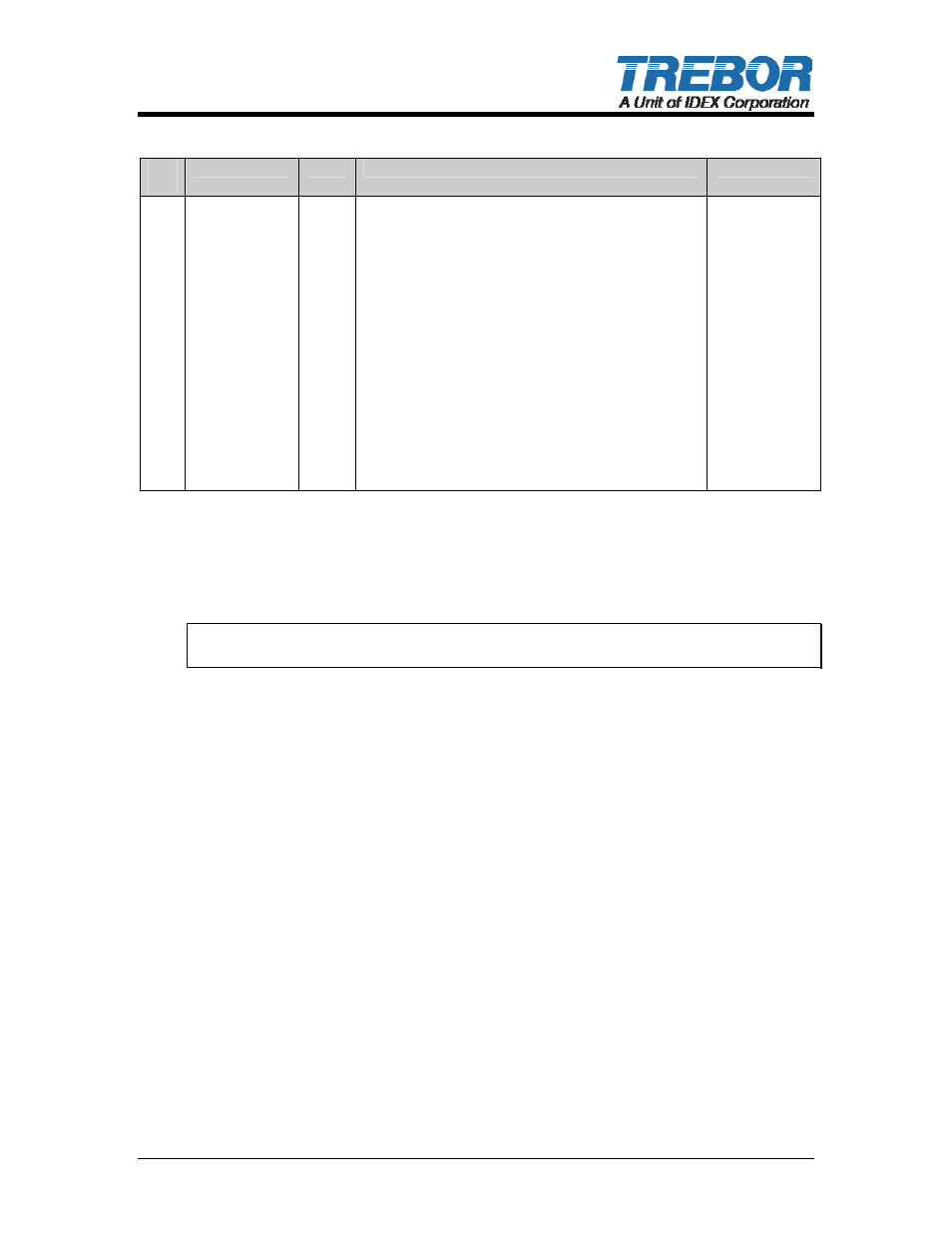

2.5 PARTS

LIST

ILL

NO

PART NO

QTY

DESCRIPTION

MATERIALS

1 AL003-01

1 Union

Nut

PVDF

(PP optional)

2 AM084

1 Seal,1.380x.63x.02

PTFE

2a L0163

1 Seal,1.75x1.00x.02

PTFE

3

AL026

1

Body, Maxim to SS95

PTFE

3a

AL027

1

Body, 960 to SS95

PTFE

3b

AL039

1

Body, Inline Connection. External

PTFE

3c

AL038

1

Body, Inline Connection, Internal

PTFE

4 1700C0047

1 Diaphragm

PTFE

5 J0093

1 Push

Plate

PTFE

6 AL019

1 Support

Plate

PTFE

7 AL014

1 Shaft

PFA

8 AL001

1 Head

PP

9 98002450

1 O-Ring

FFKM

10 AL023

1 Pilot

Seat

PTFE

11 AK020

1 Pilot

Poppet

PFA

12

AK030

1

Pilot Cap Seal

PTFE

13 AL004

1 Pilot

Cap

PP

2.6 CLEAN-UP

To help remove potentially dangerous chemicals prior to service or shipment, the

surge Suppressor should be flushed with DI water or disassembled and

thoroughly cleaned. Allow DI water to flush in and out to prevent pressure build

up. Surge Suppressor can also be submerged in a rinse tank for clean up.

NOTE: When handling Surge Suppressor, wear appropriate personal protection

gear, including safety glasses.

2.7 DISASSEMBLY

During the life of the Surge Suppressor it may be necessary to perform certain

preventative maintenance procedures to ensure its continued high performance.

This Section and Section 2.9 Assembly are provided for the user’s convenience

in disassembling and re-assembling the Surge Suppressor.

• Thoroughly clean/flush the Surge Suppressor using DI water (See Section

2.6 Clean-Up).

• Remove Surge Suppressor, from Pump or fluid line.

• Remove safety tube fitting and air inlet fitting.

• Secure Surge Suppressor in Bench mounted vice across the flats in the

head. To prevent aesthetics damage to head, use a protective barrier

between vice and head.

• Remove union nut using the strap wrench, turning the nut counter clockwise

to loosen.

• Pull the body away from the diaphragms. NOTE: Do not pry on body seal

groove, this will damage the sealing surface.

• To remove diaphragms cut a slit in diaphragm with knife and pull the

diaphragms from the support plate. NOTE: Do not pry on Support Plate seal

groove, this will damage the sealing surface.