7 clean-up, 8 disassembly, 9 assembly – Trebor PC7 User Manual

Page 12: Clean-up, Disassembly, Assembly

4.7 CLEAN-UP

Due to possible contamination all components must be flushed clean and

neutralized before disassembly to prevent fluid contact with personnel.

4.8 DISASSEMBLY

To disassemble PC7 pump controller for service, remove controller from pump by

disconnecting the flare fittings on the PC7 from the transfer tubes connecting it to

the pump.

Caution: For safety make sure air supply to PC7 has been shut off prior to

removal of supply line.

• Unscrew Adjustment Cap from controller body and carefully twist shuttle

spool from sleeve by rotating cap assembly.

• Gently remove the cap seal from the seat inside the cap to prevent any

damage or possible scratches to sealing surface. Replacement of seal is

recommended after service.

• Use a straight blade screwdriver to remove the two retaining screws from the

support plate. Next loosen compression nut and ferrule from adjustment

screw and gently push the adjustment screw out of the cap by pressing on

the end. This assembly contains the only serviceable items. See exploded

assembly for part numbers and part locations.

• Inspect parts for wear and replace if necessary.

4.9 ASSEMBLY

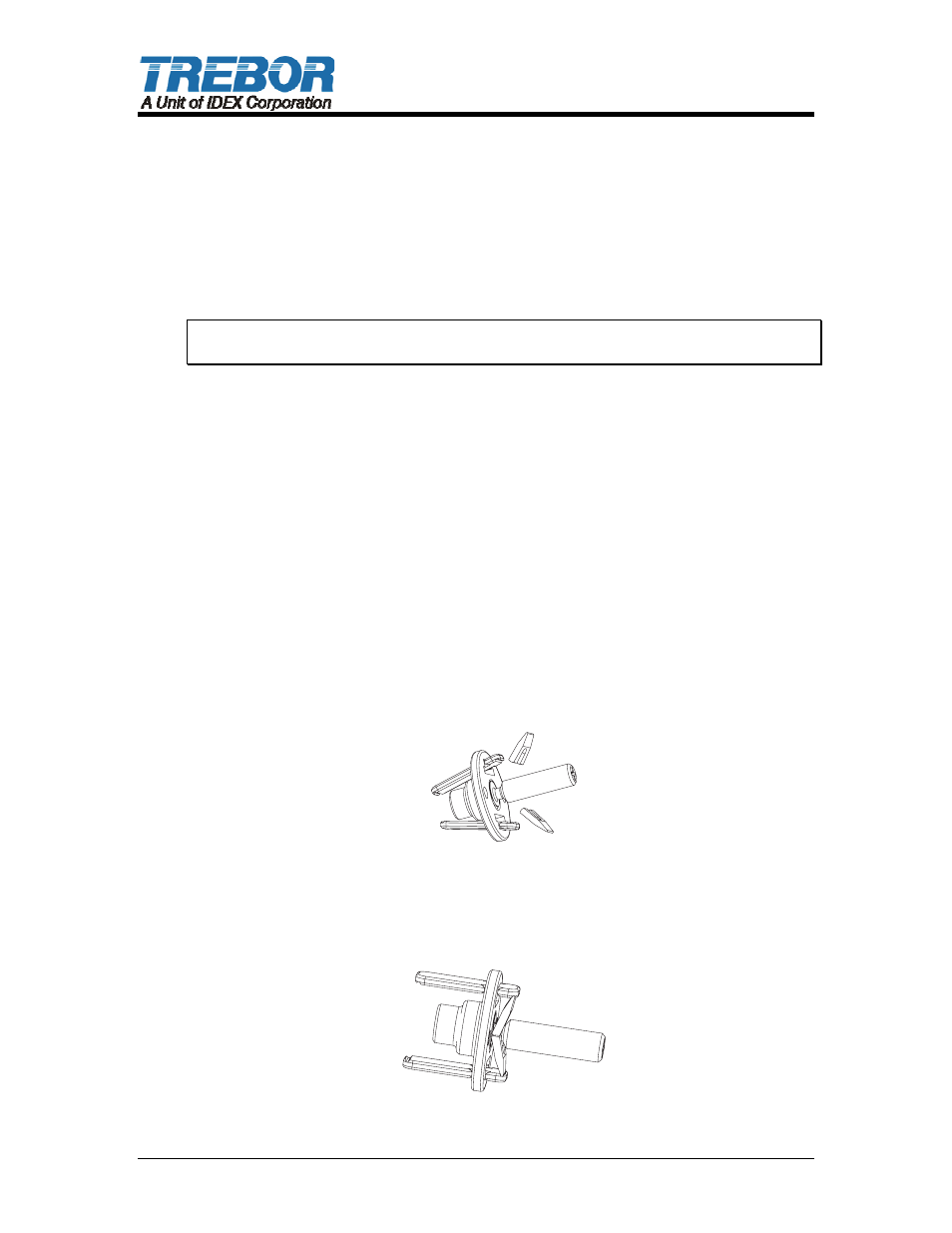

• To reassemble detent, twist the adjustment screw into the support plate and

then insert 2 each spring bars into slots as per figure 1.

MTD0 3

6 0

Figure 1

• Next insert 2 each detent legs as shown in Figure 1 and open spring bars to

lock assembly as shown in Figure 2.

MTD06 1

3

Figure 2

PAGE 12

PC7 CONTROLLER OPERATION / MAINTENANCE MANUAL