5 parts list, 6 clean-up, 7 disassembly – Trebor 110E User Manual

Page 16

PAGE 16

MODEL 110E PUMP OPERATION / MAINTENANCE MANUAL

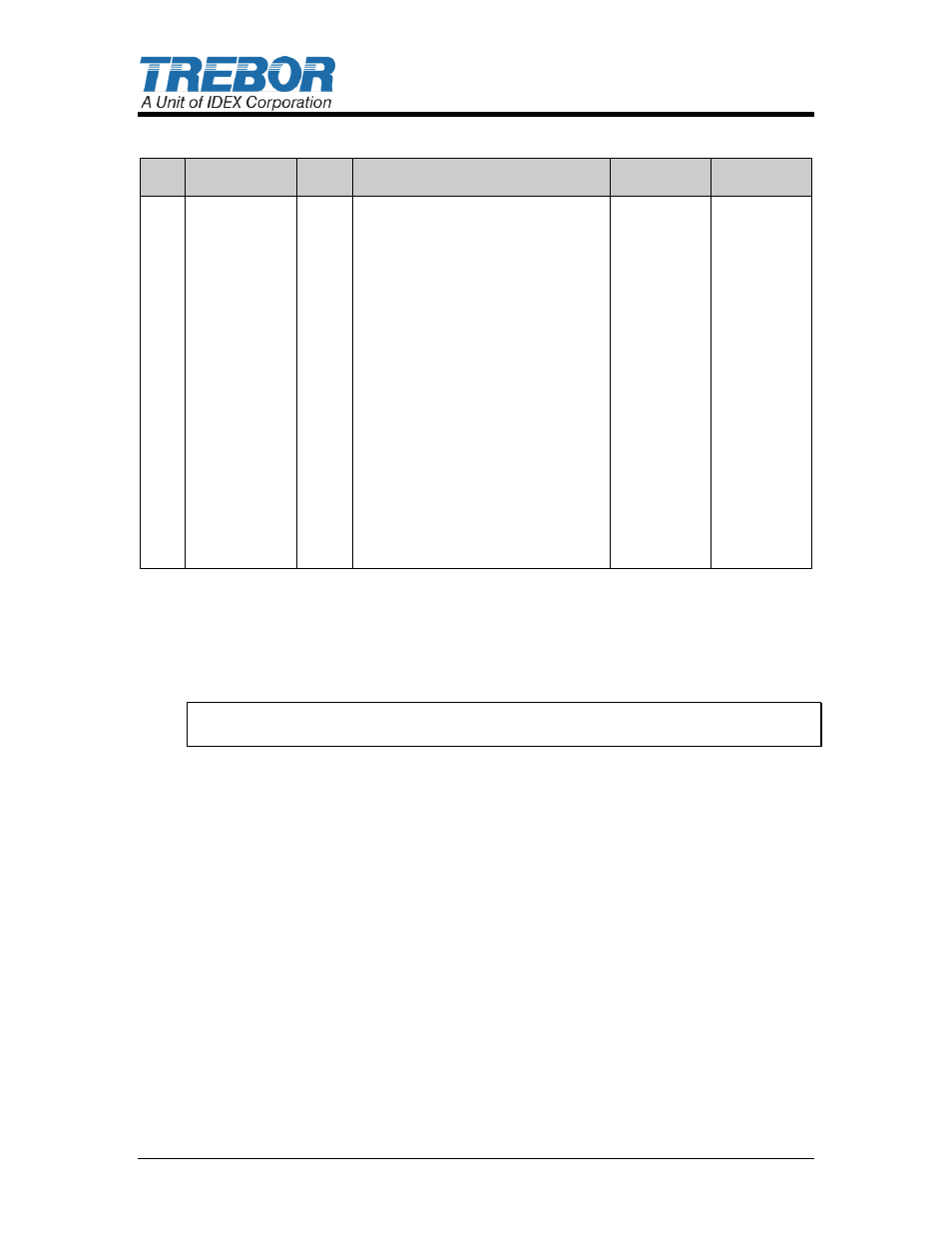

4.5 PARTS LIST

ILL

NO

PART NO

QTY

DESCRIPTION

PM

YEAR #

MATERIAL

1

J0092

1

Body

PTFE

2

98002318

4

O-ring, PTFE Check Valve

2

PTFE

3

J0097

4

Check Ball

2

PFA

4

1110B0012

2

Suction Sleeve

PTFE

5

1110B0013

2

Discharge Sleeve

PTFE

6

J0100

2

Seal

2

PTFE

7

J0101

2

Check Bore Cap

PTFE

8

98001167

2

Shaft Seal

2

PTFE

9

1110A0035

1

Shaft

2

PFA

10

J0093

2

Push Plate

PTFE

11

J0090

2

Diaphragm Set

2

PFA

12

J0094

2

Fiber Optic Target

2

PTFE

13

98001423

2

Main Seal

2

Viton

14

J0096

6

Tie Bolt Assembly

SS416, PFA

15

J0091

2

Head

PP

16

98001804

2

3/8” NPT Plug

PE

17

AM022

1

Base Mount

PP

18

98003207

4

Screw

PP

19

98003071

1

Screw

PP

20

AM023

1

Locking Lever

PP

21

C0102

1

Quick Release Base

PP

22

98001109

12

Tie Bolt Cap

2

PU

23

98002338

6

Nut, Flanged

SS18-8

4.6 CLEAN-UP

The pump fluid cavities may be flushed clean by cycling with the suction (IN) and

discharge (OUT) lines connected to a DI water flushing or rinsing tank. Flushing

using an external pressure source without allowing the pump to cycle will result in

incomplete removal of potentially dangerous chemicals.

NOTE: To effectively eliminate chemical contamination, the pump should cycle

for 10-15 minutes using the flushing DI water as described above.

4.7 DISASSEMBLY

During the life of the pump it will be necessary to perform certain preventative

maintenance procedures to ensure its continued high performance. This section

and the next (4.8

Assembly) are provided for the user’s convenience in

disassembly and re-assembly procedures.

Thoroughly clean / flush the pump using DI water (Refer to Section 4.6

Clean-Up).

Disconnect fluid and air connections from pump.

Unlock pump from quick release base by pulling out locking lever on front of

quick release base. Slide pump forward until it stops. Lift pump off quick

release base.

Remove 3/8” NPT plugs from heads.

Remove tie bolt caps from both heads.

Remove the un-tact flanged nuts from the tie bolt assemblies. Using both

3/8” nut drivers. Leave tie bolts in place.