tekmar 444 Mixing Expansion Module User Manual

Page 2

© 2007

D 444 - 04/07

2 of 4

Table of Contents

Sequence of Operation ...................................................2

System Pump Operation ................................................3

DIP Switch Settings ........................................................3

LED Status Indicators .....................................................3

Cleaning the Module ......................................................4

Error Messages ..............................................................4

Warranty .........................................................................4

The tN4 System Control determines the required mix

supply water temperature based on its settings and the

requirements of the tN4 thermostats connected to the same

tN4 bus as the 444.

The 444 operates a mixing device to maintain the required

water temperature at its Mix Supply sensor. A mixing device

can include:

•

• Variable speed injection pump.

•

• Floating action actuated mixing valve.

•

• Analog signal actuated mixing valve.

•

• Analog signal to variable frequency drive (VFD) operated

pump.

•

• Analog signal to modulating steam to hot water valve.

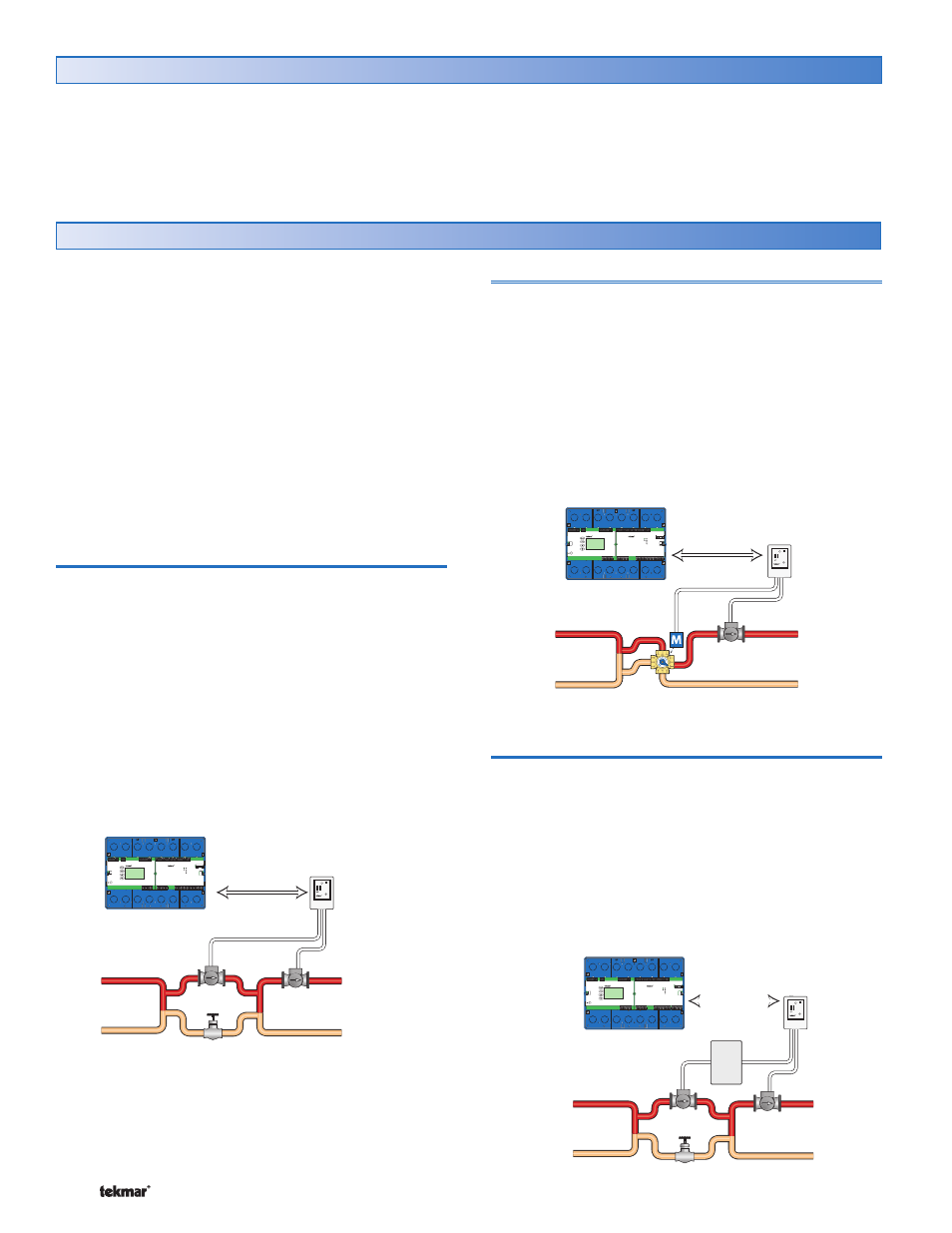

Variable Speed Injection

A standard wet rotor circulator can be connected to the

variable speed output on the back of the module. The control

increases or decreases the power output to the circulator

when there is a requirement for mixing. The circulator

speed varies to maintain the correct mixed supply water

temperature at the mix supply sensor. For correct sizing

and piping of the variable speed injection circulator, refer

to essay E 021.

A visual indication of the current variable speed output is

displayed by the Mix % Out LED bar graph.

Sequence of Operation

Floating Action

A floating action actuator motor can be connected to the

control on the Opn and Cls terminals. The module pulses

the actuator motor with 24 V (ac) to open or close the valve

in order to maintain the correct supply water temperature

at the mix supply sensor when there is a requirement for

mixing. The mixing valve that the actuator is connected to

can be either a 2-way, 3-way or 4-way valve.

A visual indication of the current variable speed output is

displayed by the Mix % Out LED bar graph.

Test

Reset

Module

Zone

Manager

444

tN4 Mix Bus

Variable Speed

Injection Pump

Mix System

Pump

Test

Reset

Module

Zone

Manager

444

tN4 Mix Bus

Mix System

Pump

Analog Signal

An analog 0-10 V (dc), 2-10 V (dc), 0-20 mA, or 4-20 mA

signal can be provided by the modulating output on the

control. The analog signal can be used to operate a

modulating mixing valve, a modulating steam to hot water

valve, or a variable frequency drive (VFD) which in turn

operates a pump.

A visual indication of the analog output is displayed by the

Mix % Out LED bar graph.

Test

Reset

Module

Zone

Manager

444

VFD

tN4 Mix Bus

Variable Speed

Injection Pump

Mix System

Pump