Rite-Ride 2312 User Manual

Warning

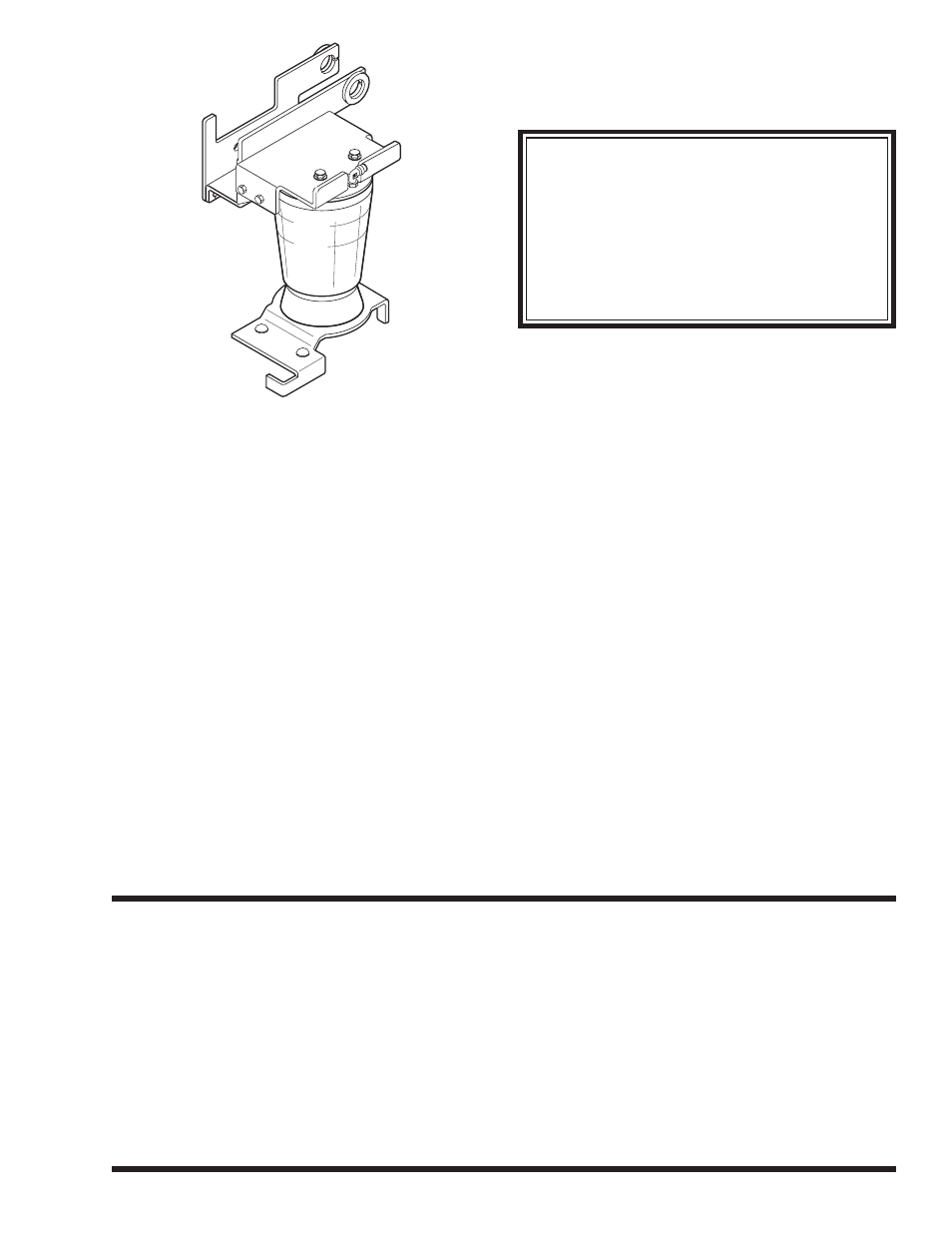

2292 / 2312

PARTS LIST

INSTALLATION INSTRUCTIONS

Congratulations—your new Air Helper Springs are

quality products capable of improving the handling and

comfort of your vehicle. As with all products, proper

installation is the key to obtaining all of the benefits

your kit is capable of delivering. Please take a few

minutes to read through the instructions to identify the

components and learn where and how they are used.

It is a good idea to start by comparing the parts in your

kit with the parts list below. If you have to remind your-

self “lefty loosey, righty tighty,” please do not proceed

with the installation.

The heart of the air spring kit is, of course, the air

helper springs. Remember that the air helper springs

must flex and expand during operation, so be sure that

there is enough clearance to do so without rubbing

against any other part of the vehicle.

Be sure to take all applicable safety precautions

during the installation of the kit. The instructions listed

in this brochure and the illustrations all show the right,

or passenger's side of the vehicle. To install the right

side assembly simply follow the same procedures.

This kit includes inflation valves and air lines for

each air spring. This will allow you to compensate for

unbalanced loads. If you would rather have a single

inflation valve system to provide equal pressure to

both air springs, your dealer can supply the optional

“T” fitting.

IMPORTANT!

For your safety and to prevent possible damage to your

vehicle, do not exceed the maximum load recommended

by the vehicle manufacturer (GVWR). Although your Air

Helper Springs are rated at a maximum inflation pressure

of 100 psi, this pressure may allow you to carry too great

a load on some vehicles. It is best to have your vehicle

weighed once it is completely loaded and compare that

weight to the maximum allowed. Check your vehicle

owner’s manual or data plate on driver side door for maxi-

mum loads listed for your vehicle.

When inflating your Air Helper Springs, add air

pressure in small quantities, checking pressure fre-

quently during inflation. The air spring requires much

less air volume than a tire and, therefore, inflates much

quicker.

WARNING:

Do not inflate this assembly when it is

unrestricted. The assembly must be

restricted by the suspension or other

adequate structure. Do not inflate beyond

100 psi. Improper use or over inflation may

cause property damage or severe personal

injury.

AIR SPRING

9002

2

LEFT UPPER FRAME BRACKET

5345

1

RIGHT UPPER FRAME BRACKET

5346

1

LEFT UPPER AIR SPRING BRACKET

5535

1

RIGHT UPPER AIR SPRING BRACKET

5534

1

LEFT INNER BRACKET

5347

1

RIGHT INNER BRACKET

5348

1

SPACER

5366

4

LOWER BRACKET

5349

2

JOUNCE BUMPER SPACER

5350

2

BRACKET CLAMP

5086

2

AXLE CLAMP

5181

2

FRAME SLEEVE

5392

2

18 FT. TUBING

0938

1

PUSH-TO-CONNECT ELBOW

3101

2

PUSH-TO-CONNECT INFLATION VALVE

3098

2

21-8248

03-11

NAD-32544-6

VALVE CAP

2

THERMAL SLEEVE

0899

2

5/16"-18 X 1" HEX BOLT

4

5/16"-18 FLANGE NUT

4

5/16" FLAT WASHER

4

3/8"-16 X 1" HEX BOLT

8

3/8"-16 X 5/8" FLANGE BOLT

6

3/8"-16 X 3 1/2 HEX BOLT

2

3/8"-16 X 2 1/2" CARRIAGE BOLT

4

3/8"-16 X 5 1/2" CARRIAGE BOLT

4

3/8"-16 FLANGE NUT

18

3/8" FLAT WASHER

2

3/8" LARGE FLAT WASHER

2

NYLON TIE WRAP

6

CAUTION TAG

2