Operation, Installation – Campbell Hausfeld FP2003 User Manual

Page 3

FP2003

3

Improper use of

grounding plug can result

in a possible risk of

electrical shock!

Do not use a

grounding adapter

with this product!

2. If repair or replacement of cord or plug

is necessary, do not connect grounding

wire to either flat blade terminal. The

wire with insulation having an external

surface that is green (with or without

yellow stripes) is the grounding wire.

Never connect

green (or green and

yellow) wire to a live terminal.

3. Check with a qualified electrician or

serviceman if grounding instructions

are not completely understood, or if in

doubt as to whether product is

properly grounded. Do not modify

plug provided; if it will not fit outlet,

have proper outlet installed by a

qualified electrician.

WIRING

Overheating, short

circuiting and fire

damage will result from inadequate

wiring, etc.

NOTE: 120 volt, 15 amp units can be

operated on a 120 volt circuit under the

following conditions:

a. No other electrical appliances or lights

are connected to the same branch

circuit.

b. Voltage supply is normal.

c. Circuit is equipped with a 15 amp

circuit breaker or a 15 amp slow blow

fuse.

If these conditions cannot be met or if

nuisance tripping of current protection

device occurs, it may be necessary to

operate compressor from a 120 volt, 20

amp circuit.

Regulator - The regulator controls the

amount of air pressure released at the

hose outlet.

ASME Safety Valve - This valve

automatically releases air if the tank

pressure exceeds the preset maximum.

Handle - Designed to move the

compressor.

Drain Petcock - This valve is located on

the bottom of the tank. Use this valve

to drain moisture from the tank daily

to reduce the risk of corrosion.

Reduce tank pressure below 10 psi,

then drain moisture from tank daily to

avoid tank corrosion. Drain moisture

from tank(s) by opening the drain

petcock located underneath the tank.

LUBRICATION

This is an oilless product and DOES

NOT require lubrication to operate.

BREAK-IN PROCEDURE

Do not attach air

chuck or other tool

to open end of hose until start-up has

been completed and unit checks OK.

IMPORTANT: Do not operate

compressor before reading instructions

or damage may result.

1. Turn regulator fully clockwise to

open air flow.

2. Turn switch to OFF position and plug

in power cord.

3. Turn switch to ON position and run

unit for 5 minutes to break in the

pump parts.

4. Turn regulator knob fully

counterclockwise. Compressor will

build to maximum preset pressure

and shut off.

5. Turn regulator knob clockwise to

cause air to bleed off. Compressor

will restart at a preset pressure.

6. Turn regulator knob

counterclockwise to shut off the air

and turn switch to Off position.

7. Attach chuck or other tool to open

end of hose. Turn the regulator on.

In the ON position, the compressor

pumps air into the tank. It shuts off

automatically when unit reaches its

maximum preset pressure. In the OFF

position, the pressure switch cannot

function and the compressor will not

operate. Make sure switch is in OFF

position when connecting or

disconnecting power cord from

electrical outlet.

Operation

22 Sp

Compresores Sin Aceite

Installation

(Con’t)

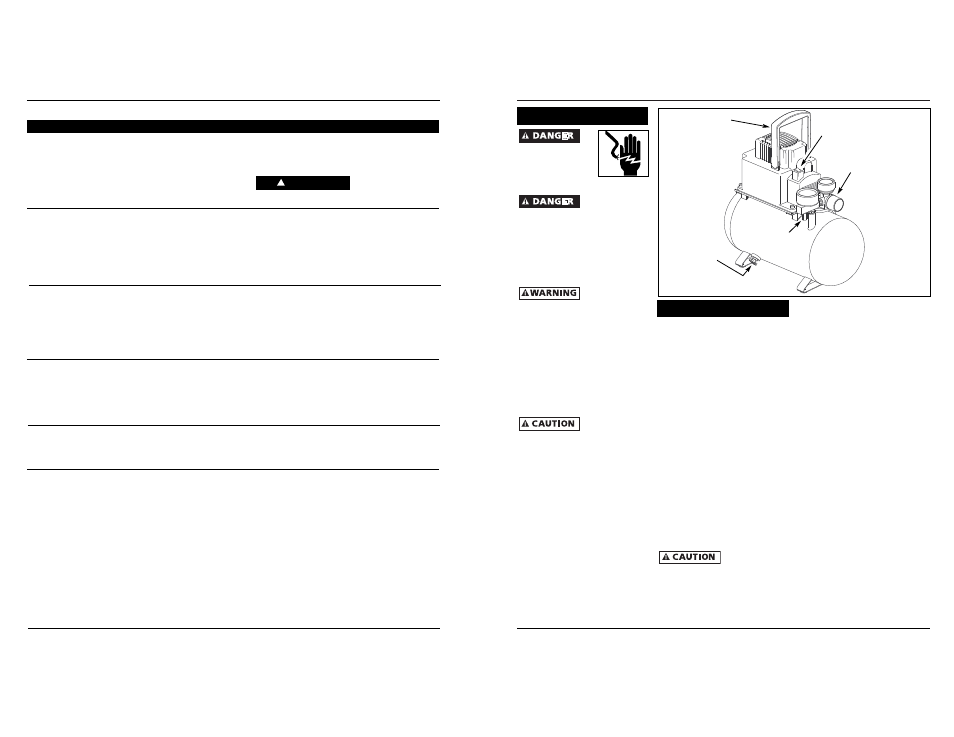

Handle

Regulator

ON/OFF Switch

Drain Petcock

Figure 2 - Unit Identification

Safety Valve

www.campbellhausfeld.com

Guía de diagnóstico de averías (Continuación)

Problema

Posible(s) Causa(s)

Acción a tomar

1. Llave de drenaje floja

2. Válvula de retención con fugas

3. Conexiones flojas en el interruptor

de presión o en el regulador

1. Uso excesivo de aire, compresor muy

pequeño

2. Fugas de aire en la tubería (en la

máquina o en el sistema exterior)

3. Válvulas de entrada rotas

4. Anillo de émbolo gastado

1. Exceso de agua en el tanque

2. Alto grado de humedad

1. Presostato defectuoso

2. Válvula de seguridad defectuosa

Condensación excesiva en el tanque

1. Ajuste

2. Re el cabezal

3. Inspeccione todas las conexiones con agua jabonosa

y ajuste

No desarme la válvula

de retención con aire

en el tanque; purgue el tanque

1. Disminuya el uso o compre una unidad con mayor

impulsión de aire (m

3

/min)

2. Cambie los componentes con fuga o ajuste como sea

necesario

3. Re el cabezal

4. Re el cabezal

1. Drene el tanque; Vire el tanque para remover todos

los residuos de humedad

2. Muévalo a una zona con menos humedad; use un

filtro en línea de aire

NOTA: La condensación de agua no es causada por

mal funcionamiento del compresor.

1. Reemplace el presostato

2. Cambie la válvula de seguridad con un repuesto

genuino

Drene con más frecuencia

!

PELIGRO

La presión del tanque

cae cuando se apaga el

compresor

El compresor funciona

continuamente y la

salida de aire es menor

de lo normal/baja

presión de descarga

Humedad excesiva en el

aire de descarga

El compresor funciona

continuamente y la

válvula de seguridad se

abre cuando aumenta

la presión

Arranques y paradas

excesivas (arranque

automático)