Rite-Ride 2071 User Manual

Page 3

FRONT

5 - 6-1/2

FRAME

1-1/2

1-1/2

NO DRILL AREA

NO DRILL AREA

DRIVER'S SIDE

FRONT

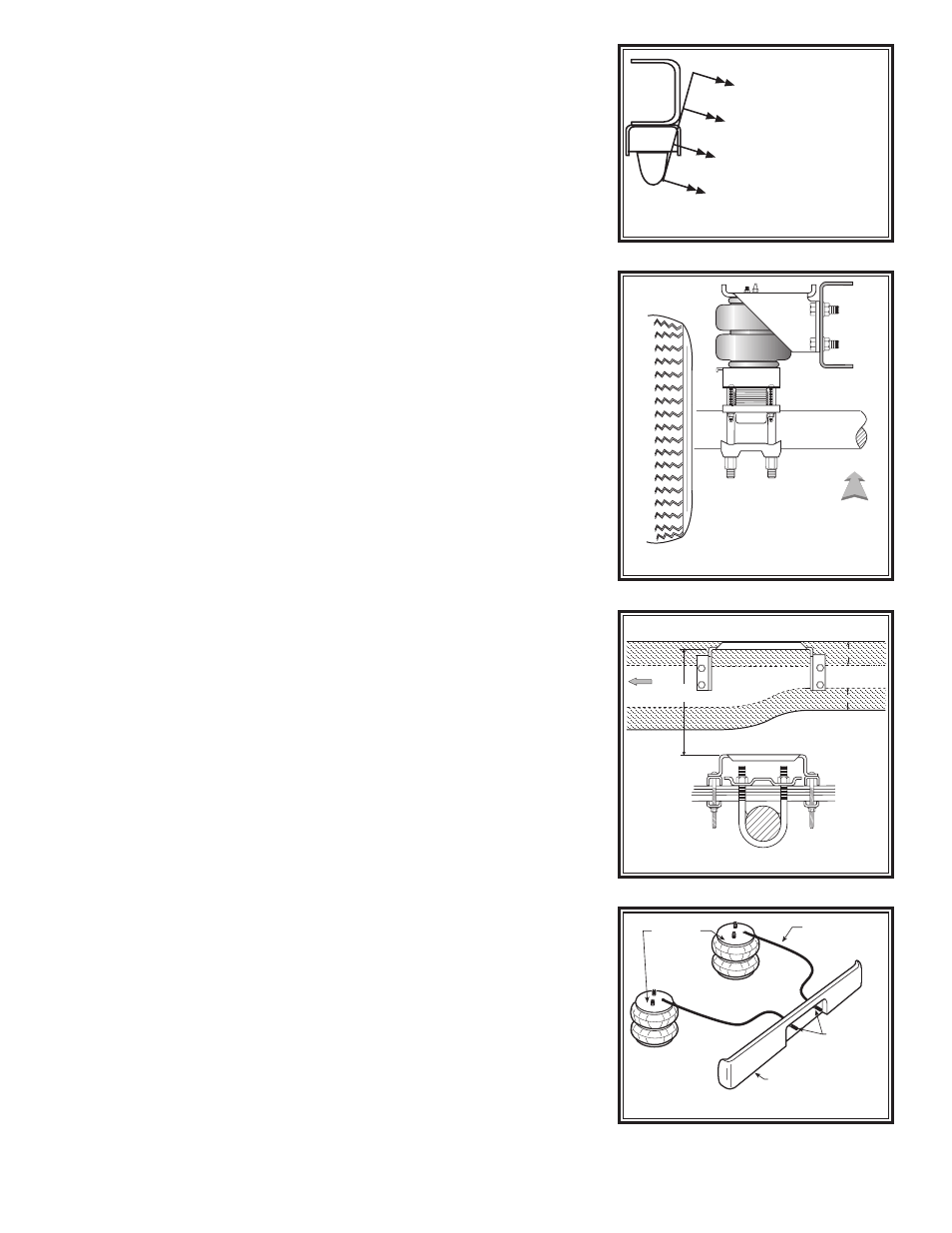

FIGURE “B”

FIGURE “C”

FIGURE "D"

FIGURE “E”

STEP 1 — PREPARE THE VEHICLE

With the vehicle on a solid, level surface chock the front wheels. Raise

the vehicle by the rear axle and remove the rear wheels. After the removal

of the wheels lower the vehicle so the axle rests on jack stands rated

for your vehicles weight. Remove any jounce bumper bracket that is not

mounted flush with the frame which will interfere with the operation of the

air helper springs see Figure “B”. Jounce bumpers located under the

frame rail may be left in place.

This installation assumes that there

is no load in the bed of the truck. Remove the negative battery cable.

On 2005 and newer Ford vehicles the emergency brake line bracket

must be relocated. Remove the screw holding the brake line. Install

the relocating bracket with the screw previously removed.

NOTE: the

bracket is marked top. Next, fasten the emergency brake line bracket

to the relocation bracket using the 3/8" X 1" bolt and a 3/8" nut.

STEP 2—PREASSEMBLE THE KIT

Select one air helper spring and an upper bracket from your kit. Align the

studs of the air spring with the mounting holes of the upper bracket and

insert. Make sure the air inlet is visible through the large access hole in

the upper bracket. Fasten the upper bracket to the air spring using the

3/8"-16 flanged lock nuts, see Figure “A”. Install the elbow fitting into

the air spring through the large access hole in the upper bracket. Tighten

the air fitting securely to engage the orange thread sealant. Position

the fitting to point to the anticipated location of the air inflation valves,

see Figure “A” & “E”. Select one lower bracket and place the bracket

so the lip of the lower bracket will be next to the tire, see Figure “A”. If

you are installing this kit on a 1987 or earlier GMC pickup or a 1994 or

earlier Dodge pickup review notices on Figure “A”. Fasten the lower

bracket using a 3/8"-16 x 3/4" flange hex bolt (finger tight) through the

center slot into the threaded hole in the air spring.

STEP 3—PRE-FIT AND MARK / DRILL HOLES

Position the air spring assembly on the leaf spring stack. The lower

bracket should straddle the leaf spring retainer and the upper bracket

mounting flanges should be flush against the frame. Depending on the

application, the lower bracket may have to be raised (i.e. interference

with “U”-bolts, leaf spring retainer, brake drum, etc...). This kit comes

with two sets of bracket straps/shims. These are included to provide

adequate clearance for the air spring and lower bracket, as well as, any

other component on the vehicle. One set is 1/2" tall while the other set

is 1" tall. To raise the air spring assembly to its maximum height, install

the 1" shim between the lower bracket and the leaf spring stack. The

remaining 1/2" strap/shim will be used to clamp the assembly to the

leaf spring stack, see Figure “D”. The bracket straps/shims may be

interchanged, or not used, to provide maximum clearance and proper air

spring height. Furthermore, the shims can be mixed (i.e. use the 1/2" on

one side and the 1" or none on the other) to adjust for leaf spring slant.

Once the height of the lower bracket has been established, adjust

the position of the upper bracket so that the mounting flanges are

flush with the side of the frame rail. To do this, slide the air spring over

the lower bracket along its slotted connection. With the brackets now

positioned properly and the air spring in proper alignment, tighten the

3/8"-16 x 3/4" hex bolt securing the lower bracket to the air spring. It

may be necessary to slide the entire assembly fore or aft along the leaf

spring in order to provide clear mounting. Before marking and drilling

the holes for the upper bracket, make sure the mounted height of the

air spring is between 5.00" - 6-1/2", that there is at least 1-1/2" between

the edge of the hole and the inside of the upper and lower frame flange

, and the upper and lower brackets are as parallel as possible,see

Figure "D". Mark the four holes to be drilled with a center punch using

the upper bracket as a template, then remove the air spring assembly.

Before drilling the holes make sure all electrical, brake and fuel

lines are cleared from the path of the drill. Damage to lines can be

avoided by inserting a piece of wood between the frame rail and any

lines in the path of the drill. Drill the four holes in the frame rail using a

3/8" drill bit, see Figure “A”.

Remove any bracket

portion that is not flush

with the frame. Either

cut it away or unbolt

and remove it.

AIR HOSE

INFLATION

VALVES

BUMPER

AIR

SPRINGS

FORD FRAME ILLUSTRATED