Coil-rite installation procedure – Rite-Ride 4100 User Manual

Page 3

COIL-RITE INSTALLATION PROCEDURE

NOTE: Check air pressure on a monthly basis.

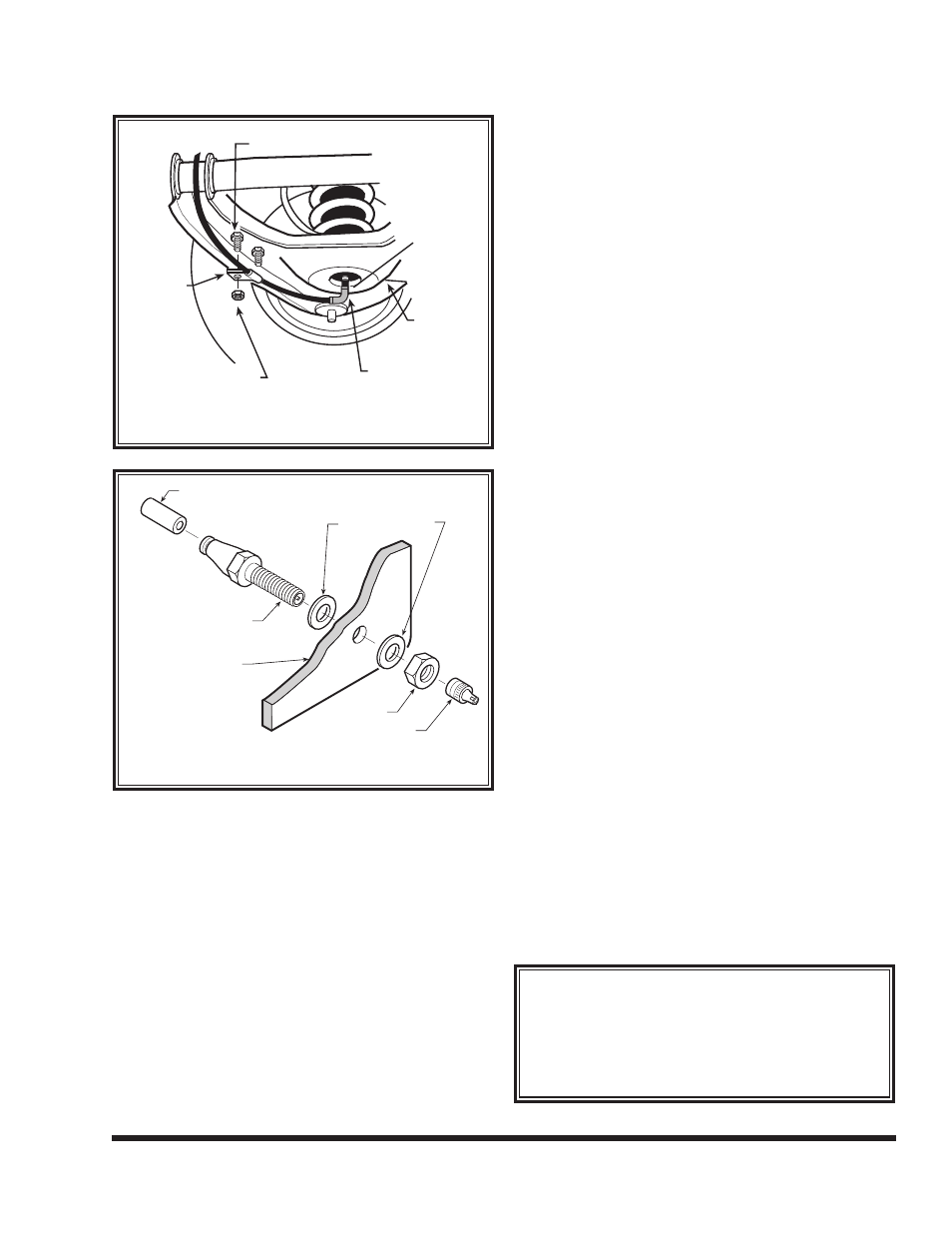

FIGURE “D”

FIGURE “E”

STEP 5—ROUTE THE AIR LINE

Cut the air line tubing into two equal lengths, making sure

the end is cut squarely (a “saw” cut with a sharp knife is

preferred). Route the air line from the elbow fitting to the

desired inflation valve location, avoiding direct heat from

the exhaust system, radiator, and away from sharp edges,

see Figure “C”. This should be a protected location, such

as under the hood or on the bumper. Do not fold or kink

the air line tubing. Insert the air line into the fitting in the

air spring. See Figure “D”.

Using the supplied nylon ties, secure the tubing to

the vehicle. Attach the air line to the A-arm by installing

the supplied clip over the existing stud in the A-arm, see

Figure “D”. Install a 3/8" -16 flanged hex nut onto the

stud over the clip. If your vehicle is not equipped with a

threaded stud on the A-arm, a 3/8" -16 x 1-1/2" bolt (not

supplied) can be used.

STEP 6—INSTALL THE INFLATION VALVE

Drill a 5/16" hole where you wish to mount the inflation

valve. Remember to keep the inflation valve in a protected

area that is easily accessible. Attach the inflation valve

to the bumper or body of the vehicle, see Figure “E”.

Cut the excess air line tubing so that it will fit easily

into the inflation valve, making sure the end is cut squarely

(a "saw" cut with a sharp knife is preferred). Push the end

of the tubing into the inflation valve as far as possible.

STEP 7—INSTALL THE OPPOSITE-SIDE AIR

SPRING

Follow Steps 2-6 to install the second air spring on the

remaining side of the vehicle.

STEP 8—COMPLETION

This now completes the installation. Jack the vehicle up

and remove the jack stands. Reattach the negative battery

cable. Remove the wheel chocks from the rear wheels.

STEP 9—INFLATE AND TEST

Check the recommended inflation pressure and inflate the

air springs to recommended maximum operating pressure

(see page 1 for operating pressures). With a soap and

water solution, check for air leaks around the fittings and

valve core. We recommend inflating and deflating in 5 psi

increments to find the ideal riding condition for your vehicle.

FOR BEST RIDE use only enough air

pressure in the air helper springs to level the

vehicle when viewed from the side (front to

rear). This amount will vary depending on the

load, location of load, condition of existing

suspension and personal preference.

PUSH-TO-CONNECT

INFLATION VALVE

BODY OF

VEHICLE

AIR LINE

FLAT WASHER

HEX NUT

VALVE CAP

“A”-ARM

3/8" - 16 FLANGED

HEX NUT

CLIP

EXISTING STUD

ELBOW

FITTING