2 drainage of condensate, 3 discharge conditions and reaction forces, 3 valve connecting dimensions – Richter KSEA/F Series Safety Valves User Manual

Page 9: 4 flange caps and gaskets, 5 direction of flow and installation, Drainage of condensate, Discharge conditions and reaction forces, Valve connecting dimensions, Flange caps and gaskets, Direction of flow and installation

Series KSEA/F

Page 9

9530-052-en

Revision 03

TM 7128

Edition 05/2008

6.2.2 Drainage of condensate

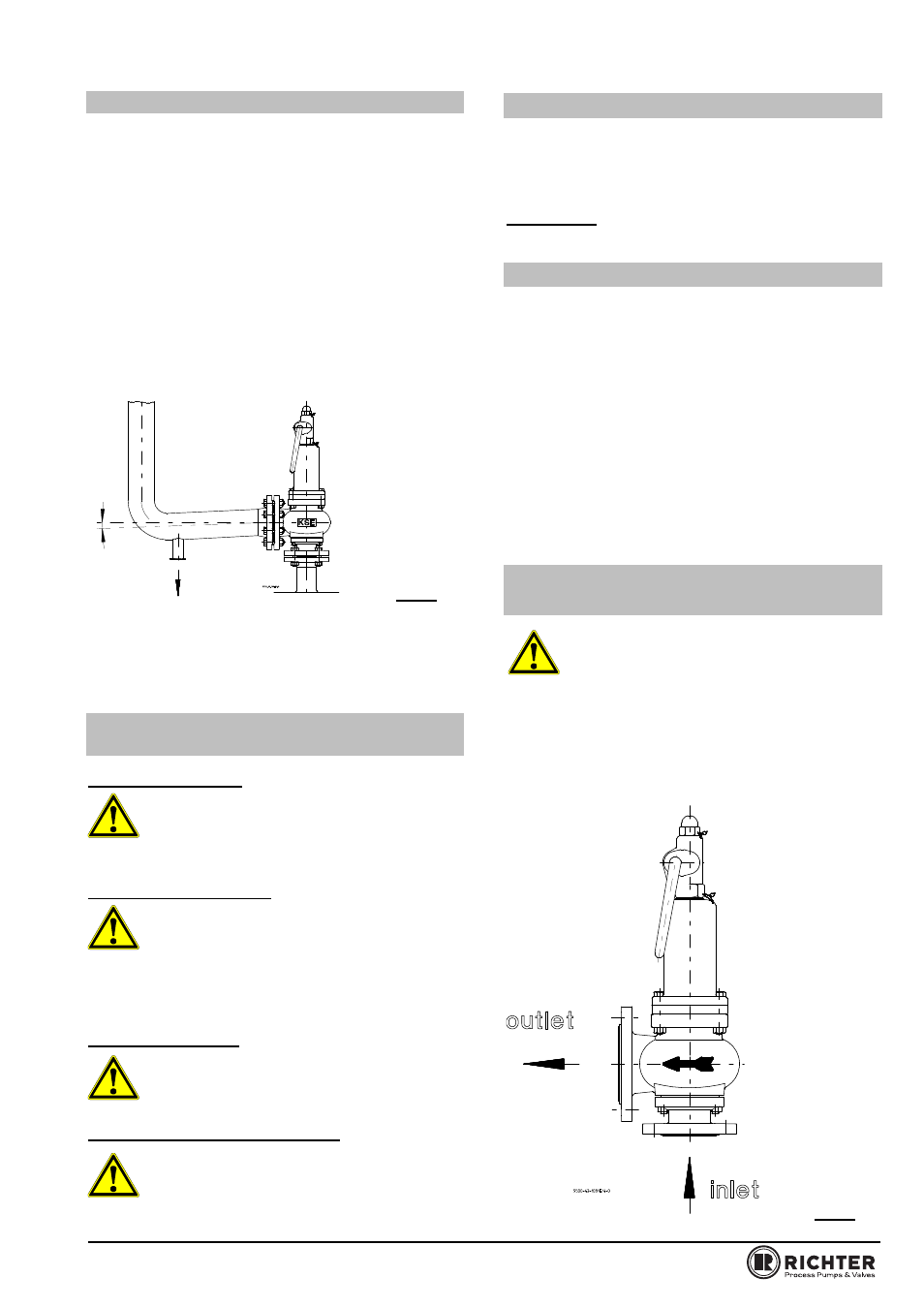

Lay horizontal pipes with a gradient away from the

valve so that the liquid medium cannot accumulate in

the valve body and that, in the case of gases, no

condensate collects in the body.

If outlet lines are laid with a geodetic level difference

(e.g. for vapours or gases with a 90° vertical upright

pipe bend out of the valve), the bend must not be

located directly downstream of the valve.

A horizontal pipe section with a gradient must firstly

be installed downstream of the valve.

A draining facility must be provided at the lowest point

in the pipe. This opening for the drainage of

condensate must be lower than the flow chamber of

the body.

Fig. 4

Lines for the drainage of condensate are to have

adequate cross sections. They are to be laid with a

gradient and must ensure safe drainage of the

medium.

6.2.3 Discharge conditions and reaction

forces

At low temperatures:

Outlet lines must be protected against

freezing. This applies in particular if gas

cooling as a result of expansion is to be

expected or lines are laid outdoors.

With crystallising media:

In the case of media which tend to

crystallise, solidify or stick, appropriate

action must be taken to ensure that the

solidification process cannot take place in the inlet or

outlet lines or in the body (e.g. installed rupture disc,

insulation, heating).

With gassing media:

In the case of gassing or vaporising liquids,

adequately dimensioned flashtraps must be

located in the direct vicinity of the valve.

Reaction forces during discharge:

The pipes and their holders are to be

dimensioned so that their weight forces and

the reaction forces and thermal loads

produced during discharge can be safely absorbed.

6.3 Valve

connecting

dimensions

The safety valves are be equipped with flange

connections to ASME B16.5 Class 150.

The dimensions of the flange connections and the

main dimensions are contained in the drawing in

Section 10.5.

6.4 Flange caps and gaskets

Contamination of or damage to the sealing surfaces is

best avoided if the protective caps remain on the

flanges until just before installation.

We recommend the installation of gaskets so that the

sealing surfaces are not damaged by the mating

flanges.

If plastic sealing surfaces can be damaged, PTFE-

lined seals with a metal inlay should be used. This

may be the case with counter-flanges made of metal

or enamel.

PTFE-lined seals are available as special accessories

from the Richter range.

6.5 Direction

of

flow

and

installation

When the valve is being installed, the

direction of flow must be observed; it is

indicated by an arrow on the valve body.

A mix-up of the inlet and outlet will result in the

valve becoming ineffective and the bellows may be

destroyed.

Always install the safety valve with the stem in a

vertical position.

Fig. 5