9 tests, 1 lift, 2 adjustment of set pressure – Richter KSEA/F Series Safety Valves User Manual

Page 18: 3 pressure setting, 4 set pressure tolerances, 5 seat tightness test, Tests, Lift 18, Adjustment of set pressure, Pressure setting

Series KSEA/F

Page 18

9530-052-en

Revision 03

TM 7128

Edition 05/2008

Lowering the bellows onto the seat

For this purpose screw the adjusting screw 538

into the spring bonnet 513 until the spacer can be

freely moved.

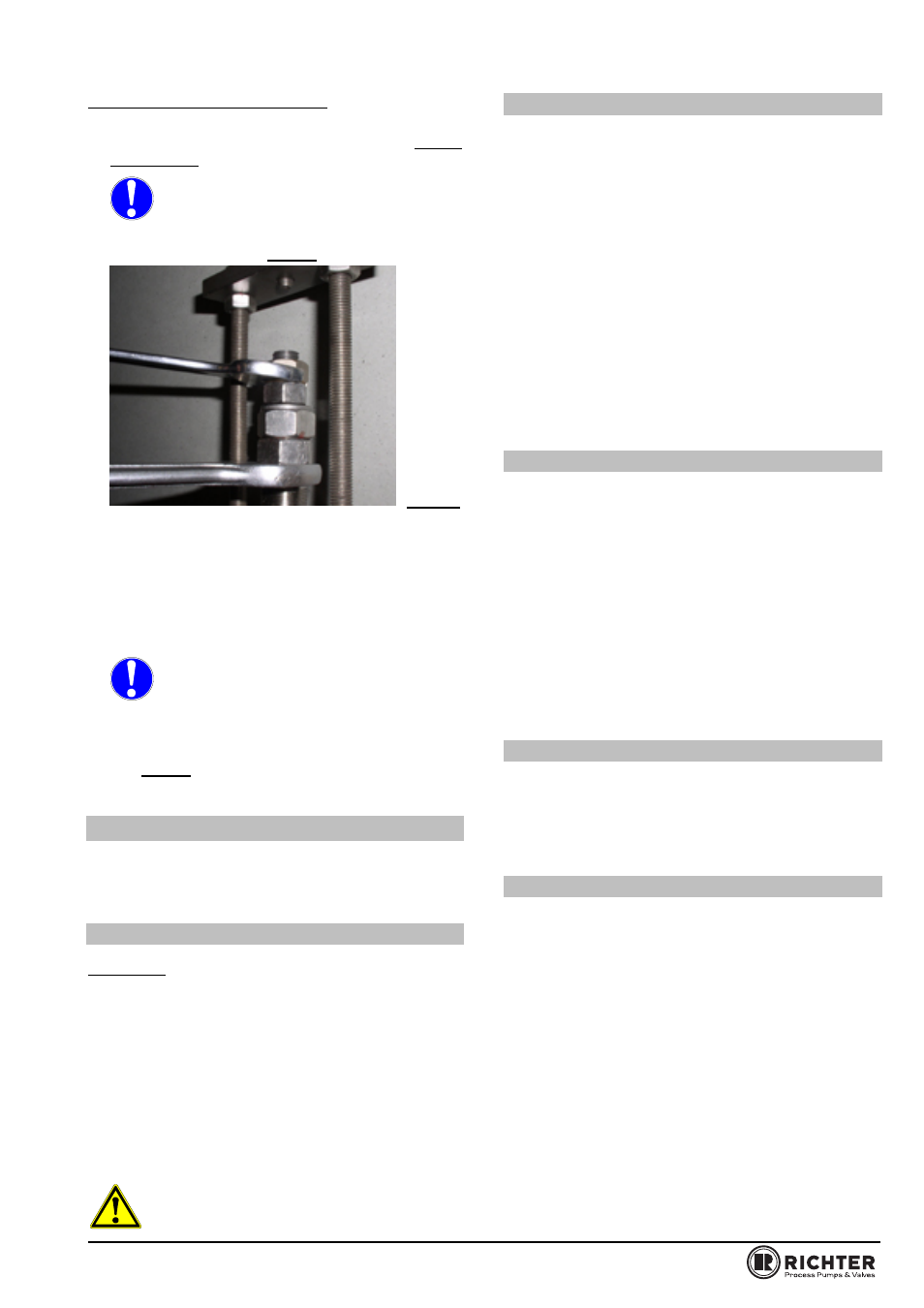

When tightening the adjusting screw 538,

hold the spindle 802 with a wrench on the

counter nut to prevent it from turning so

that the bellows 206 or the spring-type pin 939/1

are not damaged. See Fig. 25.

Fig. 25

Undo the counter nut and remove the spacer.

Now the valve can be set to the specified set

pressure.

Secure the spindle nut 534 and hex. nut with self-

locking feature 929/1 on the end of the spindle and

counter against each other. Set the adjusting

screw 538 accordingly.

When screwing the hex. nut with self-

locking feature 929/1 on or off the spindle

802 or when setting the adjusting screw

538, hold the spindle with a wrench on the counter

nut to prevent it from turning so that the bellows

206 or the spring-type pin 939/1 are not damaged.

See Fig. 25

9.9 Tests

Following the assembly of the valve, the lift and the

test pressure must be checked.

9.9.1 Lift

Lift check:

Remove the cap nut 935/1 from the lifting cap 535

and determine the height of the stem 802 up to the

upper edge of the lifting cap 535.

Determine the dimension from the raised face of

the valve inlet to the plug in both the closed and

fully opened state.

Actuate the lifting lever 238 until the mechanical

travel stop can be felt.

The measurement can be made with a slide calliper

gauge and a depth indicator to DIN 862.

The lift is derived from the difference in the

two heights. It must be at least as high as

the lift given in the test certificate.

9.9.2 Adjustment of set pressure

According to UG-136 (d)(4) each pressure relief valve

shall be tested to demonstrate its popping or set

pressure. Pressure relief valves marked for gas or

vapour may be tested with air. Pressure relief valve

marked for liquid service shall be tested with water or

other suitable liquid.

In mounted condition the KSEA/F is set by adjustment

of the screw to the required set pressure. For tests

with air the set point is the pressure at which the valve

discs moves in the opening direction a larger amount,

as compared with the corresponding movements at

higher or lower pressures.

For tests with water, the correct testing point is the

pressure measured at the valve inlet, at which the first

steady stream of liquid is visually detected at the valve

outlet.

9.9.3 Pressure setting

When a single pressure relief device is used, the set

pressure marked on the device shall not exceed the

maximum allowable working pressure of the vessel.

When the required capacity is provided in more than

one pressure relief device, only one pressure relief

device need be set at or below the maximum

allowable working pressure, and the additional

pressure relief devices maybe set to open at higher

pressures but in no case at a pressure higher than

105% of the maximum allowable working pressure.

The correct set pressure is documented on the

inspection sheet.

9.9.4 Set pressure tolerances

According to UG-134 (d)(1) the set pressure tolerance

shall not exceed ± 0,138 bar (± 2 psi) for pressures up

to and including 4.83 bar (70 psi) and ± 3% for

pressures above 4.83 bar (70 psi).

9.9.5 Seat tightness test

After completion of the tests required by UG-136

(d)(4) seat tightness test shall be conducted.

This test should take place on a test bench with a

neutral medium such as air or water.

Regarding their suitability and precision, the

employed pressure gauges must conform to the

requirements of the ASME Code Section VIII,

Division 1, UG-102.

Unless otherwise designated by a Manufacturer's

published pressure relief valve specification, the

seat tightness test and acceptance criteria shall be

in accordance with API 527-1991.

The valve shall be vertically mounted on the test

stand.

To check the seat tightness pressure, the pressure

in the valve inlet is slowly decreased until the valve

is bubble-tight.