8 maintenance, 9 electric peripheral equipment, Maintenance – Richter MNKA Series (ASME) User Manual

Page 8: Electric peripheral equipment, Series mnka, Acc. to asme, Not certified to atex

Series MNKA,

acc. to ASME

Page 8

9250-050-en

Revision 11

TM 7903

Edition 07/2010

During operation of the pump it must be ensured that

excessive deposits of dust are prevented (regular

cleaning) in order to prevent the pump surface from

heating to above the admissible temperature.

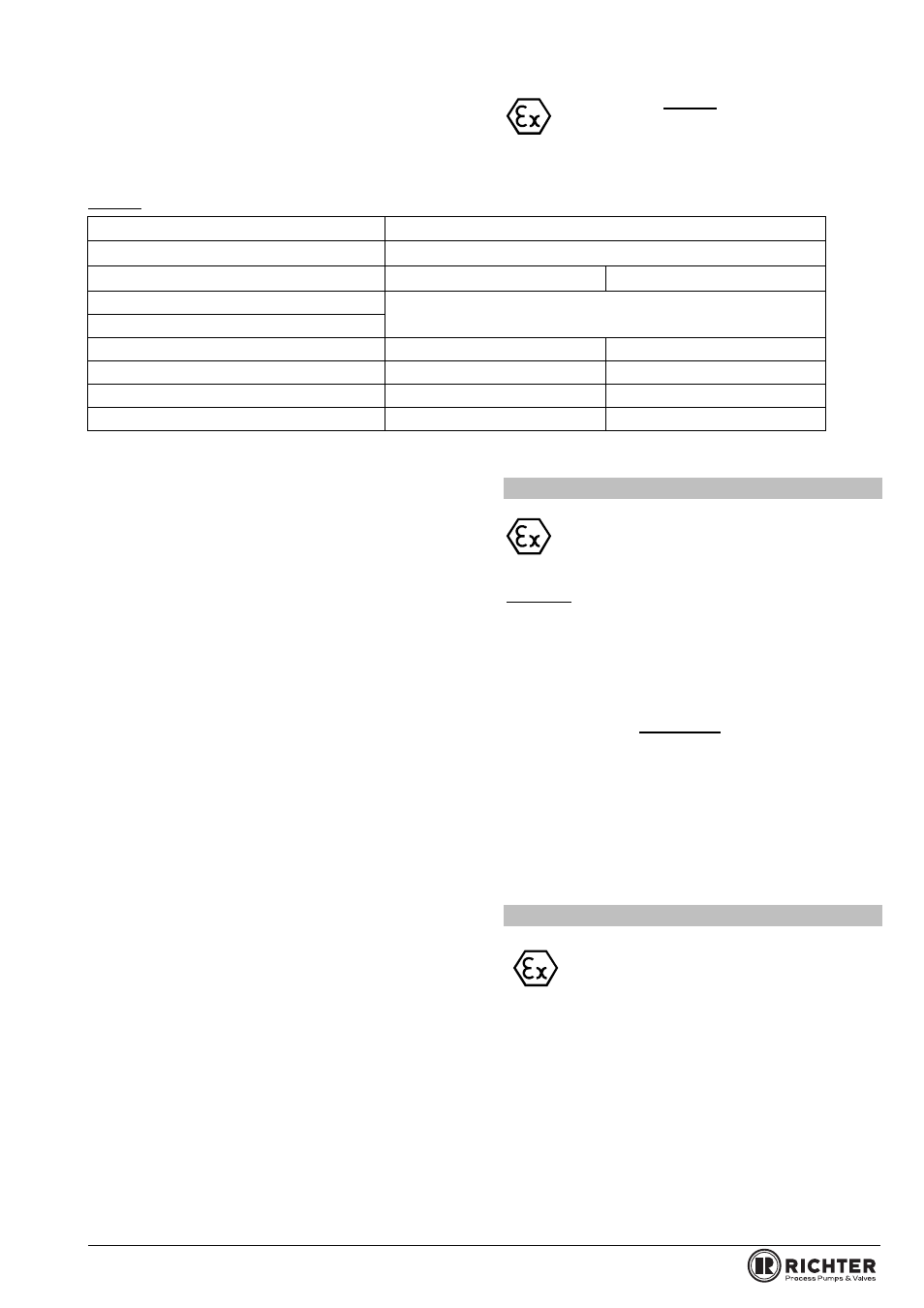

The following Table 1 contains the resultant

theoretical limit values of the temperature of

the liquid medium allowing for the temperature

classes according to European EN 13463-1.

Table 1

Temperature class acc. to EN 13463-1

Limit value of the temperature of the fluid

Lining material

PFA/PTFE

Can material

4)

CFK-F

CFK-H

T6

85 °C (185 °F)

not certified to ATEX

T5

100 °C (212 °F)

T4

135 °C (275 °F)

125 °C (257 °F)

1) 2)

125°C (257°F)

1) 2)

T3

200 °C (392 °F)

150 °C (302 °F)

180 °C (356 °F)

3)

T2

300 °C (572 °F)

150 °C (302 °F)

180 °C (356 °F)

3)

T1

450 °C (842 °F)

150 °C (302 °F)

180 °C (356 °F)

3)

1) Long life grease lubrication : no restriction.

Oil bath lubrication: standard version with shaft seal T3

labyrinth seal (special design)

T4.

2) The limit values specified for the temperature of the fluid at the

pump inlet are determined for the most unfavourable case (high

speed, low flow, low heat capacity of the medium, ....). Under

favourable operating conditions the limit values specified may

be increased by up to 5 K after consultation with the manu-

facturer.

3) Consult the manufacturer for higher limit values.

4) The can material has been list in the data sheet.

The plant customer must ensure that the

prescribed operating temperature is observed.

The maximum admissible temperature of the

liquid medium at the pump inlet depends on the

temperature class and the selected lining material

required in each case.

Observance of the temperature class T4 with oil

bath lubrication is not possible with the standard

shaft seal. A labyrinth seal must be used instead

of the shaft seal for the temperature class T4 and

with oil-lubricated rolling bearings.

2.6.8 Maintenance

For safe and reliable operation, it must be

ensured with regular inspection intervals that

the unit is properly serviced and kept in a

perfect technical condition.

Example: Functioning of the ball bearings. The mode

of operation and operating conditions largely

determine the actual service life that can be attained.

Regular checks of the bearings and their running

noise can prevent excess temperatures due to hot-

running bearings, collision of the outer magnet

assembly against the lantern or even defective

bearing seals. See Section 7.2.

In regard to media containing solids, the maintenance

intervals must be set by the operator in accordance

with the conditions of operation.

If auxiliary systems (e.g. external flushing, cooling,

heating) are installed, a check must be made to see

whether monitoring facilities are required to safeguard

their operation.

2.6.9 Electric peripheral equipment

Electric peripheral equipment, e.g. pressure,

temperature and flow sensors etc. must

comply

with

the

prevailing

safety

requirements and explosion protection provisions.