RCBS Tube Pistol Bullet Feeder User Manual

Page 5

Install the Bullet Die assembly into your press (See

ADJUSTMENT section for proper setup). Where you

choose to install the Bullet Die depends on the press

that you are using. For RCBS five station presses,

station four (4) is the most common position. See

Photo 1.

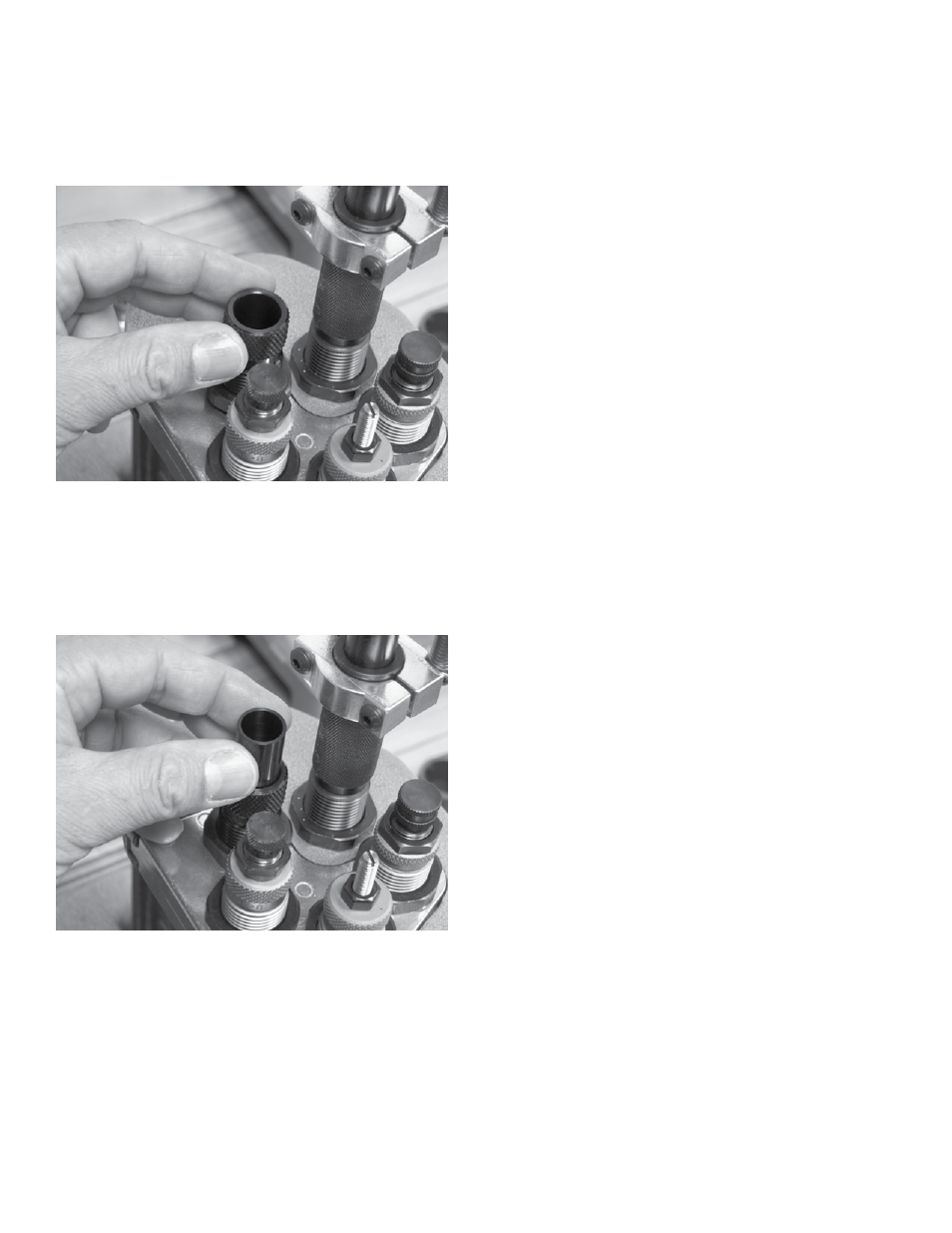

Install the Bullet Guide into the die body, the tapered

inner portion is the “top” of the guide with the stamp

ID up and readable. Bullet guides are stamped on the

side for identification. See Photo 2.

Place the plastic Clear Feed Tube into the top of the

Bullet Die.

OPERATION

Fill the Feed Tubes. The Bullet Guide in the top of

the Bullet Die aligns the bullet for feeding through

the Bullet Fingers. The case will expand the Bullet

Fingers and allow one bullet to be placed on the

case mouth. As the case is retracted, the Bullet

Fingers close, preventing the next bullet from passing

through the Bullet Die.

The weight of the bullet stack puts enough pressure

on the placed bullet to prevent it from falling off the

case as it moves to the next station to be seated and

crimped. Add more bullets to the Feed Tube as need-

ed. NOTE: The Small Tube Bushing is required for

use with the small Clear Feed Tubes, (380/9mm/38).

NOTE: Additional tubes are available.

ADJUSTMENT

The position of the Bullet Die must be adjusted to

properly place the bullet on the case mouth at the

top of the press stroke. This is a trial and error

adjustment.

Case mouths must be belled/flared .030” over the

bullet diameter. For example:

.380/9mm

.385”

.38/.357

.387”

.40 S&W

.430”

.45 ACP

.481”

Failure to flare cases .030” over bullet will not allow a

bullet to drop from the Bullet Fingers. With the Bullet

Die partially threaded into the press and the plastic

Clear Feed Tube filled with bullets, run a properly

flared case up into the Bullet Die. Thread the Bullet

Die into the press until you hear a bullet drop or see

the bullet stack move down. Thread the Bullet Die

down a further ½ turn and temporarily lock the Bullet

Die lock ring. Run another properly expanded and

flared case up into the Bullet Die to check the setting.

If a bullet is placed on the case and no other bullets

fall through the die, the setting is correct. Lock the

Bullet Die lock ring. If a bullet is not fed, loosen the

Bullet Die lock ring and thread the die down in ½ turn

increments until the proper setting is achieved.

NOTE: If you are loading 170-grain or heavier

.38/.357 bullets, the Bullet Finger with four marks

and the .38 Bullet Guide marked “38L” with the

stepped inner base must be used together.

MAINTENANCE

Disassemble the Bullet Die body and clean the Bullet

Guide and Bullet Fingers to ensure smooth function.

Photo 1

Photo 2

5