RCBS Bullet Feeder - Pistol Kit User Manual

Page 6

- 6 -

Install the Bullet Guide into the die body, the tapered

inner portion is the “top” of the guide. Bullet guides are

stamped on the side for identification.

Photo 6

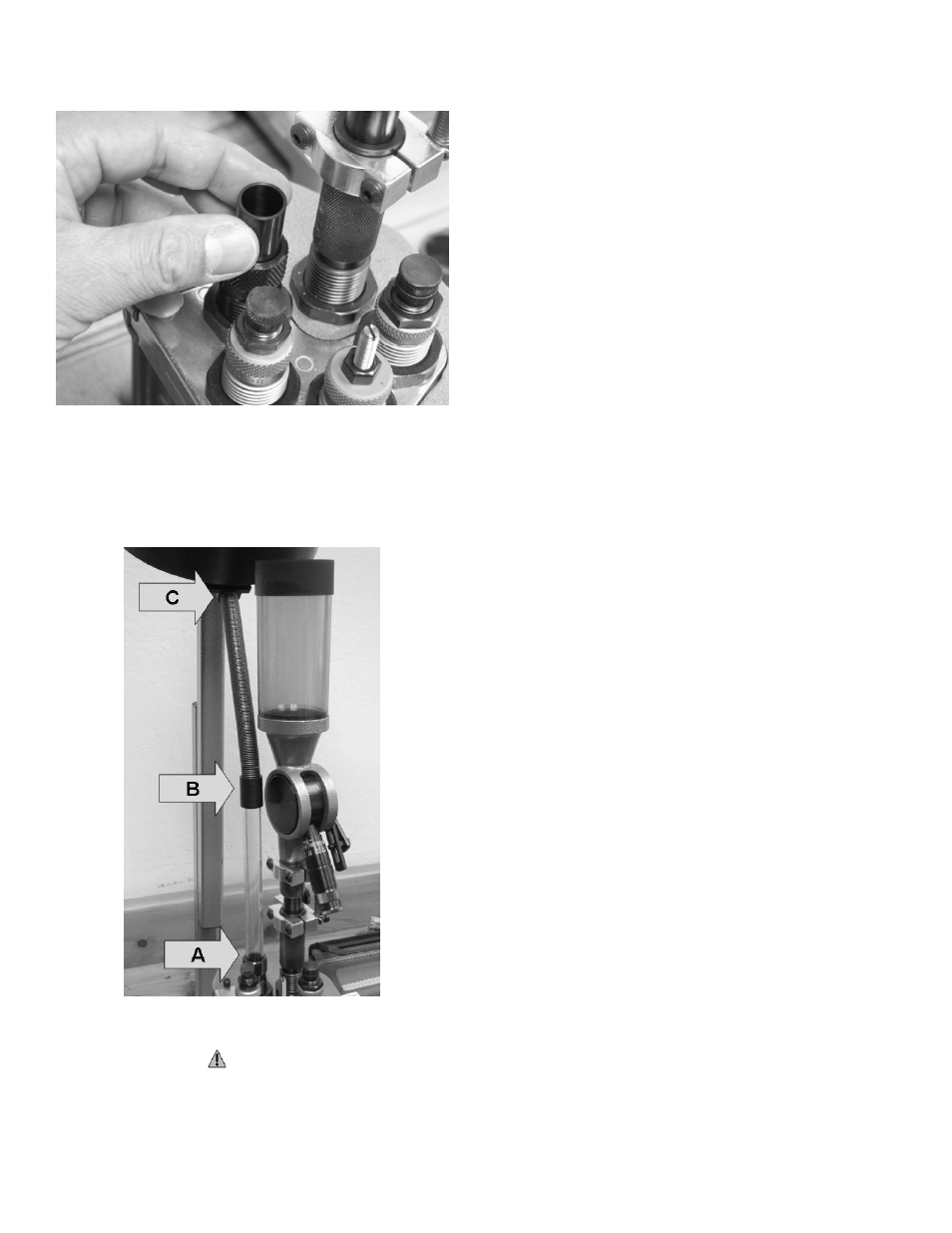

Place the proper plastic Lower Clear Tube(A) into the

top of the Bullet Die and place the Tube Adapter(B) on

the top.

Install the Continuous Spring tube into the top of the

Tube Adapter and into the Bowl assembly(C).

Photo 7

For short 9mm and .38 bullets, the Upper Tube 9mm

needs to be installed.

CAUTION Move the micro

switch out of the way to install the 9mm Upper Tube

adapter. Failure to do so will cause the switch to break,

the motor will then not shut off and continually feed

bullets potentially burning out the motor or breaking

parts in the Bowl.

When you are ready to load, fill the Bowl with ~100

bullets and connect the Power Supply. The Bowl will run

until the feed Tubes fill up with bullets. Add another ~100

bullets to bowl.

You are now ready to begin your loading session.

OPERATION

With the Bowl filled with bullets and power applied, the

Bullet Wheel will orient the bullets and fill the feed

Tubes.

The Bullet Guide in the top of the Bullet Die aligns the

bullet for feeding through the Bullet Fingers.

The case will expand the Bullet Fingers and allow one

bullet to be placed on the case mouth. As the case is

retracted, the Bullet Fingers close, preventing the next

bullet from passing through the Bullet Die.

As the press handle is operated and a case is brought

up into the Bullet Die, a bullet will be placed on the case

mouth. The weight of the bullet stack puts enough

pressure on the placed bullet to prevent it from falling off

the case as it moves to the next station to be seated and

crimped.

Add more bullets to the Bowl as needed. NOTE: The

sorting plate may not feed the last 10-20 bullets

ADJUSTMENT

Bullet Die

The position of the Bullet Die must be adjusted to

properly place the bullet on the case mouth at the top of

the press stroke. This is a trial and error adjustment.

Case mouths should be belled/flared .030” over the

bullet diameter. For example:

9mm

.385”

.38/.357 .387”

.40

S&W .430”

.45

ACP .481”

With the Bullet Die partially threaded into the press and

the plastic Lower Clear Tube filled with bullets, run a

properly flared case up into the Bullet Die. Thread the

Bullet Die into the press until you hear a bullet drop or

see the bullet stack move down. Thread the Bullet Die

down a further ½ turn and temporarily lock the Bullet Die

lock ring. Run another properly expanded and flared

case up into the Bullet Die to check the setting. If a bullet

is placed on the case and no other bullets fall through

the die, the setting is correct. Lock the Bullet Die lock

ring. If a bullet is not fed, loosen the Bullet Die lock ring

and thread the die down in ½ turn increments until the

proper setting is achieved.

Depending on how level your reloading bench is or the

type of bullet that you are using, you may need to

change the angle position from the middle 35° to 40° or

45°. A steeper or shallower angle is achieved by moving

the Bracket Pin to one of the other positions.