Plumbing, Electrical connections, 2 plumbing 3.3 electrical – HF scientific 19998 Triple Validation Turbidimeter - 0-100 NTU User Manual

Page 12: Connections

TVT 1 (5/02)

6

Rev. 2.6 (.pdf)

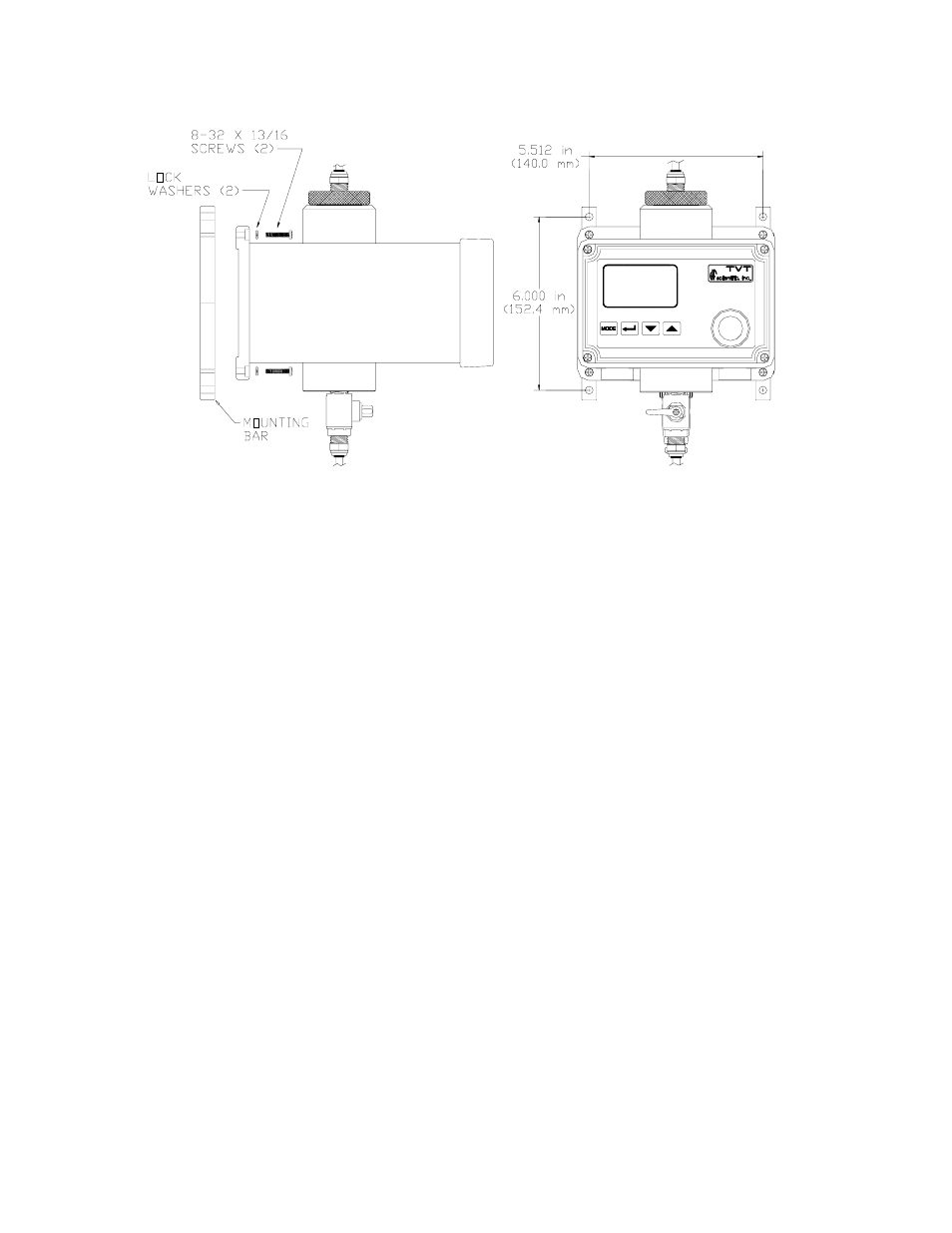

Figure 4: Use of the optional mounting bars to ensure isolation of the 4-20 mA output

3.2 Plumbing

The recommended plumbing for the instrument is shown in Figure 3. The instrument is

designed to limit the flow to the range of 0.4 – 0.6 liters/minute depending on the system

backpressure. Ensure that you supply the instrument with a process flow capable of

sustaining this level. Quick-connect fittings are supplied on the inlet and outlet of the

instrument; these fitting help speed up calibration procedures. These fittings will accept

0.25” OD x 0.170 ” ID tubing. Opaque tubing should be used if the tubing will be

exposed to sunlight

3.3 Electrical Connections

All of the electrical connections to the TVT except power, are made through cables

located on the lower section of the instrument. While facing the instrument, the right

connector is used for power supply (15 –18 VDC) connections. The middle cable is used

for the relay contact connections. The left cable provides the communication signals. As

you read the following sections, please refer to Figure 4 for clarification of the electrical

connections.

Please follow all local and government recommendations and methods for installation of

electrical connections to and between the instrument and other peripheral devices.

Note: Only qualified electricians should be allowed to perform the installation of the

instrument as it involves a line voltage that could endanger life.

Power: The input power connector is pre-assembled with either universal or a wall

mount power supply. Alternatively, if you can supply clean 15 –18 VDC to the system

you can do so without using a power adapter. In this instance the cable used for power

has 4 pins for connections. The connections are shown below: