Installation instructions continued, Step 7: connecting electrical and supply tubing, Figure 7 – Bradley Smoker MG-2/TT User Manual

Page 12

Express® Lavatory System - MG-Series with TouchTime® Control

MG-2/TT

Installation Instructions

12

2/8/07

Bradley Corporation • 215-1480 Rev. E; EN 06-915

B BLACK

G BROWN

F BROWN

A BLACK

LEFT

BUTTON

LEFT

GRAY

RIGHT

GREEN

RIGHT

GRAY

RIGHT

BUTTON

LEFT

GREEN

VERNATHERM

THERMOSTATIC

MIXING VALVE

COMPRESSION

NUT

TRANSFORMER

S83-134

A BLACK

C BLACK

D BLACK

E BROWN

F BROWN

G BROWN

H BROWN

RIGHT GRAY

RIGHT GREEN

LEFT GREEN

B BLACK

LEFT GRAY

GREEN

SUPPLY

TUBE

RED

SUPPLY

TUBE

Figure 7

Installation Instructions continued . . .

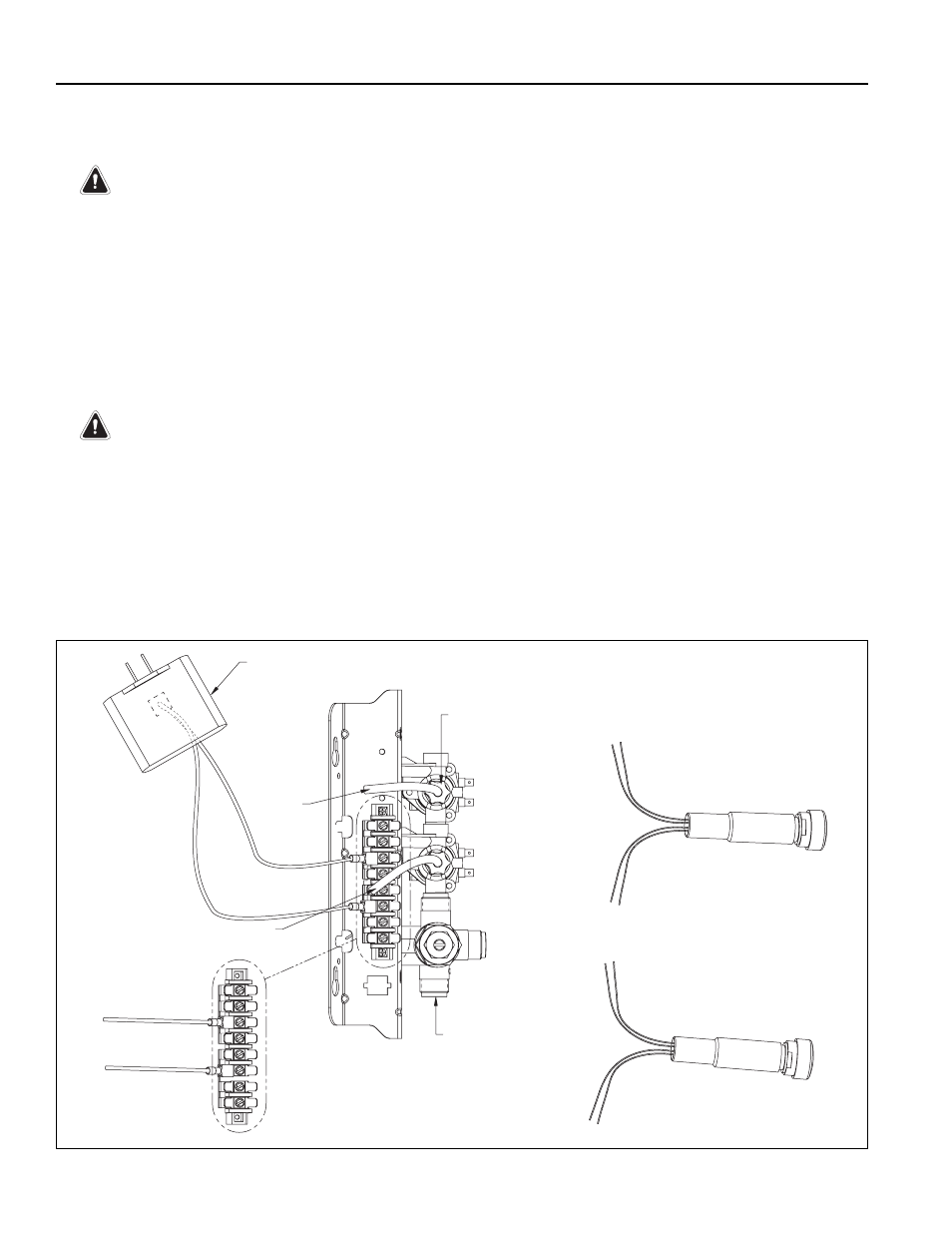

Step 7: Connecting electrical and supply tubing

WARNING: MG-2/TT must be connected to 24 VAC Class II plug-in transformer provided.

Connection to 110 VAC may cause personal injury and/or damage to electronics.

Connection of leads other than shown may cause permanent damage to the switch.

1. Insert the two sprayhead supply tubes into the two solenoid tube connectors by loosening the

compression nut and firmly pushing the tubing into the connector until the tubes are fully seated,

then re-tighten the compression nut (hand-tight plus two full turns with a wrench) (see Figure 7).

2. Connect the wires per the wiring diagram shown below.

3. Align the mounting screws with slots on the frame. Valve bracket slides down to lock into place.

4. Turn on the water supply to the MG-2/TT Express® and check for leaks.

5. Turn on the electrical power, trigger the TouchTime® push buttons and check for proper function

(the timing is electronically controlled and set at 15 seconds).

IMPORTANT: The Vernatherm™ valve is NOT factory-preset. Upon installation, the valve

temperature must be checked and adjusted to assure delivery of safe water

temperature. Water in excess of 110°F (43°C) may cause scalding.

6. Check the temperature when approximately1.0 GPM water flow is reached and adjust if

necessary (the range of the valve is 95°F–115°F (35°C–43°C). To adjust the temperature, first

loosen the temperature locking nut with a wrench. Then using a blade screwdriver, turn the

adjustment stem counterclockwise to increase the temperature or clockwise to decrease the

temperature. Once desired temperature is reached, tighten the nut to prevent temperature change.

7. Reinstall panel to frame with the five Torx-head screws provided (see Figure 3 on page 8).

NOTE: Push button activation takes place only when released, (prevents “hold open” activation).