GBC H925 User Manual

Page 8

14

15

HeatSeal Sprint H925 - Lamination Tips

for Optimum Performance

TM

®

Selection of media/paper requirements

The following is a guide to selecting the proper paper for this unit to perform at an optimum level.

Before laminating important or unique documents always run a test document through the

laminator using a similar media. If you find that your printed media is not compatible with the

H925, try a different media and/or a different print engine.

* Certain finishes (levels of gloss), weights and ink compositions may require the user to feed

single sheets into the laminator rather than stack loading.

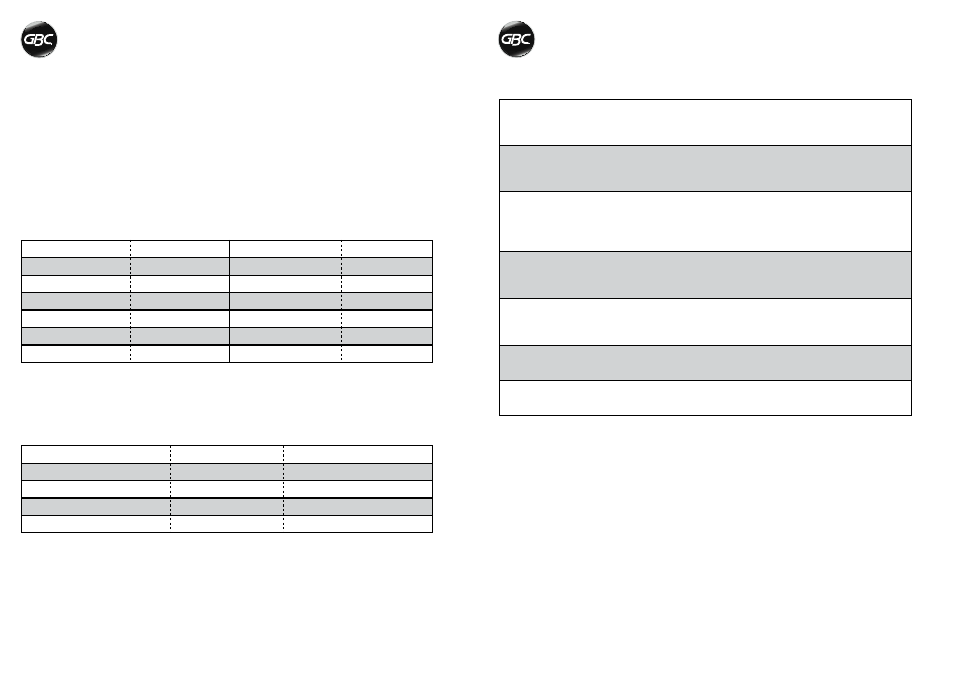

Size & finish/weight

Size: The minimum width that can be fed through the H925 is 6” or 152 mm. Standard paper

sizes that will automatically feed into the laminator are as follows: (leading edge into machine

is indicated in

bold)

Finish/weight: As stated above, even standard media can change from time to time due to

circumstances that cannot be controlled by GBC. It is always recommended that the user

experiment with the media prior to loading a full run into the feed tray. The media range that will

optimize performance of the feeder when stack loading is as follows*:

Type

Letter

Legal

Menu

Size

11” x 8.5”

8.5” x 14”

11” x 17”

Half-letter

8.5” x 5.5”

Executive

10.5” x 7.25”

Government legal

8.5” x 13

Type

Government letter

A4

A5

Size

10.5” x 8.5”

297 x 210 mm

210 x 148 mm

B5

250 x 176 mm

F4

210 x 330 mm

Media

Standard copy/bond paper

Cover stock

Index stock

Minimum Weight

20lb / 75gsm

28lb / 75gsm

42lb / 75gsm

Maximum Weight

53lb / 203gsm

80lb / 216gsm

110lb / 203gsm

Porous photo paper

20lb / 75gsm

Up to 50lb / 200gsm

Media such as double sided printed output, designer papers, card stocks, cover stocks, high

gloss photo papers, glossy photo cards and others with specialized coatings should be fed into

the laminator one sheet at a time to avoid mis-feeding or jamming the feeder mechanism.

HeatSeal Sprint H925 - Lamination Tips

for Optimum Performance

TM

®

IMPORTANT: When laminating any media that is longer than letter/A4 in the landscape orientation,

the exit tray MUST be folded back into the machine. Failure to do so will result in a jam caused by

the finished media not having enough room to clear the rollers once laminated.

The exit tray was designed to only stack letter/A4 and smaller media in the landscape orientation.

Capacity of this tray varies based on overall thickness of media and film mil used. GBC recommends

emptying the exit tray frequently.

Loading

Exit tray

Before loading prints, fan sheets on all four sides. This creates a small layer of air between the

sheets that will help the feeder mechanism by eliminating any blocking that may have occurred

while the sheets were drying or while in storage.

To maximize the film usage for letter/A4 stock, it is best to load the prints into the feeder tray

with landscape orientation. For legal/A3 stock, the media must be loaded with portrait

orientation.

If your document is severely curled, or warped, it may pose a feeding problems for the H925

feeder. To minimize this potential issue you can try to eliminate the curl by rolling the media

stack in reverse prior to loading the document. You may also try loading the document upside

down or backwards.

When loading a stack of prints, it is best to square off the bottom edge of the stack by lightly

tapping the entire stack on a flat surface. Loading the feeder tray with the bottom of the stack

squared will help eliminate mis-feeds.

Ensure the paper side guides on the document feed tray are properly spaced to rest against the

edges of the paper without compressing the stack. If paper side guides are not against the

media, sheets can skew during lamination.

Once media is loaded into the feeder tray, the lamination run must conclude before adding

more prints. DO NOT add more pages to the feed tray while lamination job is in process.

The film rolls will laminate more total pages per refill if the maximum width is utilized when

loading media into the feed tray.