Control centering, Adjusting a clevis or ball link – E-flite Carbon-Z Scimitar BNF User Manual

Page 13

EN

Control Centering

• Make sure servo directions (reversing) on your transmitter are

correct. Ensure control surfaces move freely by performing a

Control Test.

• Make sure trim and sub-trims are set to zero.

• Make sure the servo arms are set to 90 degrees. If not, remove

a servo arm and put the arm in a spline position closest to the

90 degree position (perpendicular to the servo’s long axis). If 90

degrees exactly cannot be reached, use the sub-trim on your

transmitter to adjust the servo arm to the 90 degree position.

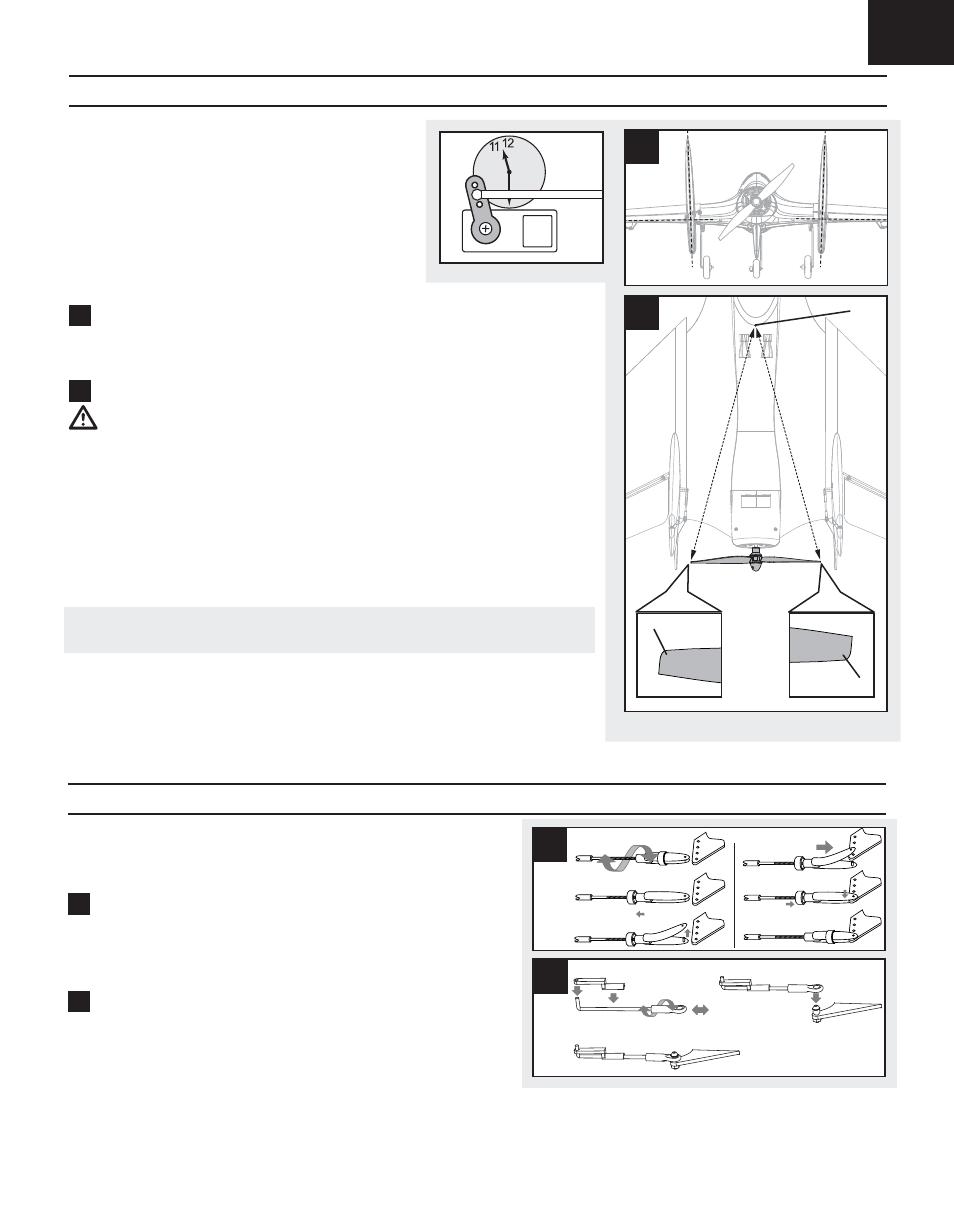

• The Vectored-Thrust (VT) servo arm is neutral at the 11:30

position (on a clock face) (A) when looking down from above

while standing at the rear of the airplane. This neutral position

gives the VT servo maximum throw in both directions.

1

Elevons and Rudder Centering

• The center for the elevons is alignment with the trailing edge of the fuselage between the rudders.

• The center of the rudders is alignment with the center of the vertical fi n to which the rudder

is attached.

2

Vectored-Thrust Centering

CAUTION: Always disconnect the fl ight battery from the ESC before handling the propeller or

injury could result.

• Turn the propeller to horizontal on the model.

• From above the model, measure from the right end of the propeller (leading edge tip (B) to the center

of the back of the canopy (C).

• Measure from the left end of the propeller (leading edge tip (D)) to the center of the back of the

canopy (C).

• These two measurements (A to B and B to C) are the same distance when the VT unit is centered.

Nose Gear Centering

• The center for nose steering occurs when the model follows a straight path while the rudder input is

at neutral.

TIP: When needed, turn the ball link or clevis until the control surface is at the center position

(up/down or left/right).

Refer to your transmitter’s manual for instructions about making adjustments to control surfaces,

Sub-Trim and Reverse.

1

2

C

B

D

After binding a transmitter to the model receiver, set trims and sub-trims to 0,

ensure servo arms are in the correct positions, then adjust clevises or ball links

to center the control surfaces.

Tip: Turn the clevis or ball link clockwise or counterclockwise on the linkage.

1

Adjusting a Clevis

• Pull the silicone tube from the clevis to the linkage.

• Carefully spread the clevis and put the clevis pin in a selected hole in the

control

horn.

• Move the tube to tighten the clevis on the control horn.

2

Adjusting a Ball link

• Connect the ball link to the ball installed on the control horn using pliers or

ball link pliers.

• Install the linkage in a hole in the servo arm using a link cover.

A

D

E

F

B

C

1

A

B

C

D

2

Adjusting a Clevis or Ball link

A

13