Equipment specifications, Installation, Start-up – Watts OF1665-75 User Manual

Page 3

3

Specifications

Inlet Connection

2” PVC Union with Socket.

Outlet Connection 2” PVC Socket

Temperature

40° - 110°F

pH

6.5 to 8.5

Ferrous Iron, Max* 0.3 mg/L

Manganese, Max* 0.05 mg/L

Copper, Max*

1.3 mg/L

Water Pressure

15 min, 100 max (PSI)

Equipment Specifications

OneFlow

®

systems are complete, self-contained,

loaded with media, and ready to use. A simple

inlet and outlet connection is all that is required

for installation. Please review operating pressures,

temperatures and water chemistry limitations to

ensure compatibility.

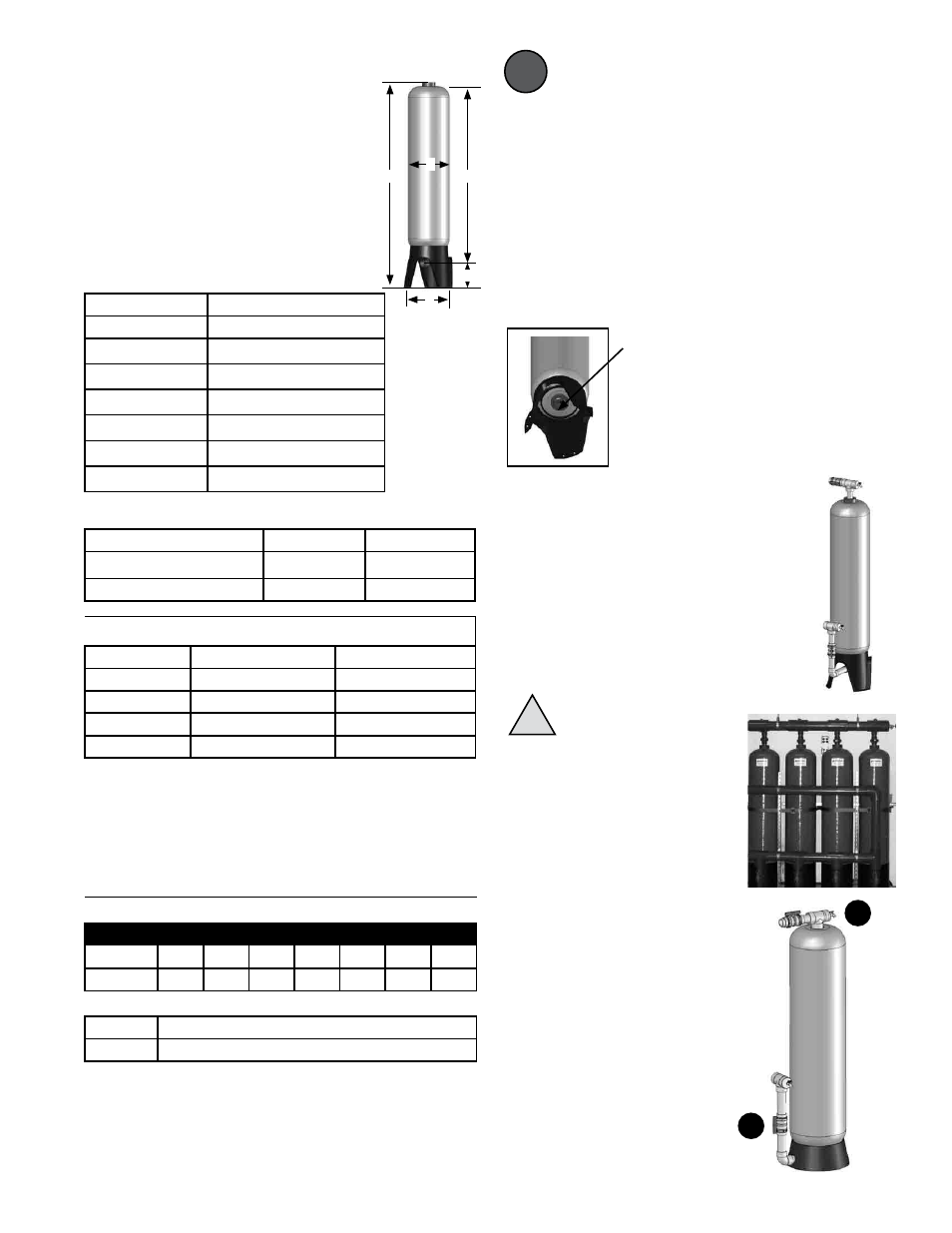

Mechanical Specifications

MODEL

1465

1665

Dry Weight (lbs)

54

68

Service Weight (lbs)

350

420

Dimensions

(nominal - inches)

a

17

17

b

14

16

c*

79

79

d

65

65

e*

10.25

10.50

* The overall height and the height of the inlet fitting varies due

to material variations and assembly tolerances. Please allow ad-

ditional clearance above the tank for making connections.

c

d

a

Installation

Tighten the Tank Bushings

Lay the tank down and check the bushings

on the inlet and outlet (bottom and top) of the

tank. It is common for them to loosen during

shipment. Tighten the bushings with a strap

wrench as needed

Install Piping

Connect the inlet and outlet plumbing according to

your preferences and any applicable local codes.

Include sample/drain ports with hose-bibb con-

nections on the inlet and outlet piping to facilitate

startup and service.

NOTE: We recommend the installation of a dual-union ball-valve

on the inlet and outlet to isolate the tank for servicing.

NOTE: A full bypass should be installed so that the full service

flow can be routed around the system as needed for servicing.

NOTE: The OneFlow

®

system operates in the Up-Flow mode

which is opposite of a conventional softener. The inlet is on the

bottom, the outlet on the top.

Important Notes!

!

i

Support the Piping

The full weight of the piping and

valves must be supported by uni-

strut, pipe hangers or other means.

The tank connections cannot sup-

port the weight of the piping. This

photo from a multi-tank system

installation shows properly supported

piping.

Tank bushing.

Rotate Clockwise

to tighten.

Start-Up

1

2

Connect a hose to the hose bibb on the

outlet of the tank. Run the hose to a drain.

Slowly / partially open the supply water

ball valve. Allow the tank to slowly fill with

water. When a steady stream of water ap-

pears at the drain, close the supply valve.

Open the inlet and outlet valves on the

system. Transfer the bypass valves from

Bypass to the Service position. Open

a nearby faucet downstream from the

OneFlow

®

system to relieve any air.

Check for leaks. Repair as needed.

The system is now ready for service.

MaximumServiceFlow(gpm)vs.Water

Temperature

ContinuousDutySystems:

System

40°F

45°F

50°F

55°F

60°F

65°F

70°F

14-65

40

44

48

50

50

50

50

16-65

45

51

56

59

63

69

75

IntermittentDutySystems:

14-65

50 GPM at all temperatures

16-65

75 GPM at all temperatures

* Intermittent duty is defined as less than 2 hours of Maximum

Flow per 24 hour period. Higher Flow rates can be achieved by

combining systems in an array.

e

b