Materials, Pressure - temperature, Installations – Watts 800M4QT User Manual

Page 2: Dimensions – weights, Standards, Approvals, Notice

Materials

Springs

Stainless Steel

Bonnet

Celcon

Vent Disc

Silicone Rubber

Disc Holder Float Polypropylene

Check Valve Disc Silicone Rubber

Check Valve Seat Noryl Plastic

Body

Bronze

Pressure - Temperature

Temperature Range: 33°F to 140° (0.5°C to 60°C)

Maximum Working Pressure: 150psi (10.3 bar)

Installations

This valve is designed for installation in a continuous pressure

potable water supply system 12" above the highest point of

the downstream piping. The valve must be installed with the

supply connected to the bottom and in a vertical position. Allow

adequate space for periodic inspection, servicing or testing.

The valve should not be installed in an area where freezing or

spillage will cause damage. Adequate drainage/freeze protec-

tion must be provided in cold weather applications. 1.5psi (10

kPa) must be exerted against the float spring to seal the float

and air inlet. Do not undersize supply and discharge piping.

Vacuum breakers are not designed, tested or

approved to protect against backpressure backflow or water ham-

mer shock. For protection against backpressure backflow, install

Watts 909/009 Reduced Pressure Zone Backflow Preventer. For

Protection against water hammer shock install a Watts Series 15

Water Hammer Arrestor utilizing good plumbing practice.

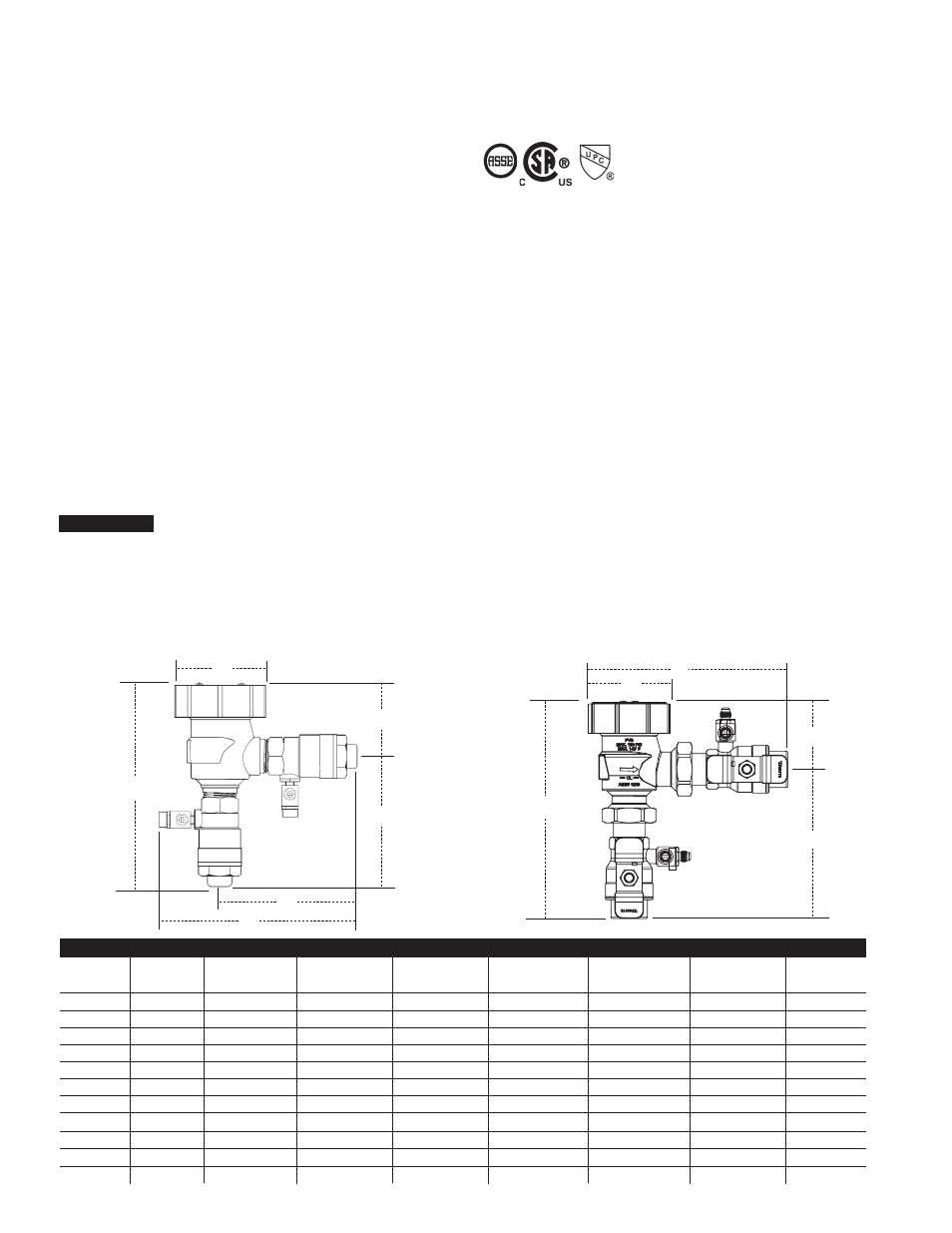

Dimensions – Weights

800M4QT

Standards

ANSI, USC

Approvals

Approved by the foundation for Cross-Connection Control and

Hydraulic Research at the University of Southern California. (

1

⁄

2

"

– 2" (15 - 50mm) 800M4QT only)

CSA (

1

⁄

2

" – 2" (15 - 50mm) 800M4QT only).

**QC models have quick-connect adapters which attach sepa-

rately to the approved 800M4QT

D

C

E

A

G

B

C

D

A

G

B

moDEl

SizE (DN)

DimENSioNS

WEiGht

A B C D E G

in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kg.

800M4QT

1

⁄

2

15 6

1

⁄

8

156 6

1

⁄

4

159 2

9

⁄

16

65 3

11

⁄

16

94 3

7

⁄

8

98 2

1

⁄

4

57 4 1.8

800M4QT

3

⁄

4

20 6

1

⁄

2

165 6

1

⁄

2

165 2

9

⁄

16

65 3

15

⁄

16

100 4

1

⁄

8

105 2

1

⁄

4

57 4 1.8

800M4QT 1 25 7

1

⁄

2

191 7

1

⁄

2

191 2

3

⁄

4

70 4

3

⁄

4

121 4

7

⁄

8

124 3

7

⁄

16

87 6 2.7

800M4QT 1

1

⁄

4

32 8

7

⁄

8

225

9 229 3

1

⁄

4

83 5

3

⁄

4

146 6

1

⁄

8

156

5 127 11 5.0

800M4QT 1

1

⁄

2

40 9

1

⁄

4

235 9

1

⁄

2

241 3

1

⁄

4

83 6

1

⁄

4

159 6

3

⁄

8

162

5 127 14 6.3

800M4QT 2 50 10

5

⁄

8

270 9

5

⁄

8

245 3

1

⁄

4

83 6

3

⁄

8

162 7 178

5 127 19 8.6

U800M4QT

3

⁄

4

20 6

3

⁄

8

163 7

9

⁄

16

192 2

1

⁄

8

55 5

7

⁄

16

138 – – 2

1

⁄

4

57 4 1.8

U800M4QT 1 25 8

5

⁄

16

211

9 229 2

13

⁄

16

71 6

3

⁄

16

158 – – 3

7

⁄

16

87 6 2.7

800M4QT-QC

1

⁄

2

15

7

7

⁄

8

200

8 203 2

13

⁄

16

71

5

7

⁄

16

138

5

5

⁄

8

144

3

7

⁄

16

87

4.5 2.0

800M4QT-QC

3

⁄

4

20

8

1

⁄

2

216 8

1

⁄

2

216

2

13

⁄

16

71

5

11

⁄

16

144

6

1

⁄

8

156

3

7

⁄

16

87

4.7 2.1

800M4QT-QC 1 25

9

1

⁄

2

241

9

1

⁄

2

241

2

13

⁄

16

71

6

3

⁄

4

171

6

7

⁄

8

175

3

7

⁄

16

87

6.6 3.0

1020

U800M4QT

NOTICE

**

**

**