Flow measurement, Operation, Fig. 5 – Watts TDV User Manual

Page 3: Fig. 6

Valve Size

2

1

⁄

2

3

4

5

6

8

10

12

Number of Rings

5

5

6

9

10

12

18

28

(valve full open)

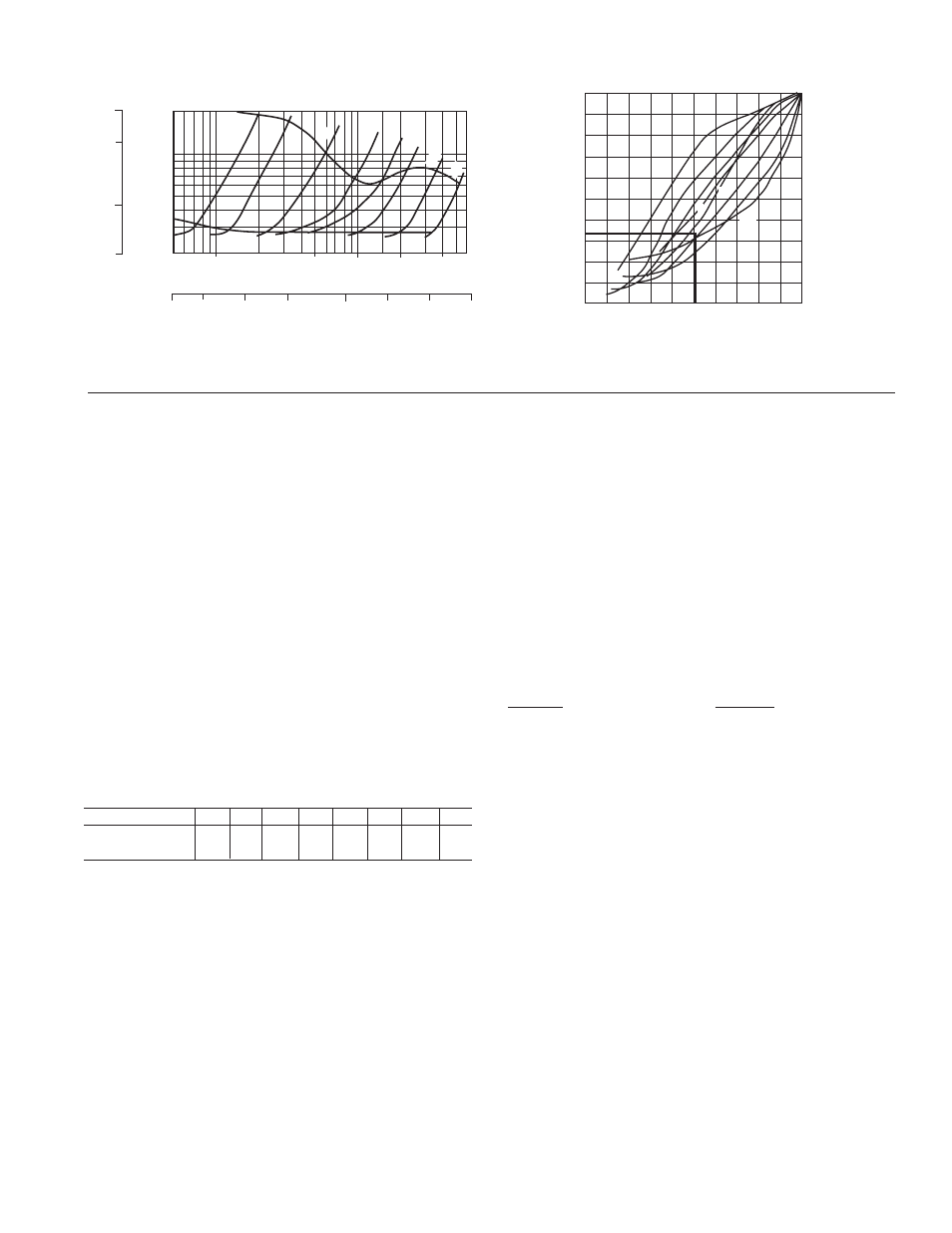

Flow Measurement

1. Where approximate indication of flow is acceptable the Watts

Series TDV valve can be used.

2. Flow Measurement Valve in Wide Open Position

1. Measure and record the differential pressure across the

valve using a Watts Series PG meter.

CAUTION: Safety glasses should be used.

2. Refer to Series TDV Performance Curves with valve in full

open position (Fig. 5).

Locate Pressure Differential on left hand side of chart and

extend line horizontally across to valve size being used.

Drop line vertically down and read flow rate from bottom of

chart.

3. Determining Flow Rate with Valve in Throttled Position

1. Record the size of valve and stem position using the Flow

Indicator Scale (on page 3) Calculate percentage of valve

opening referring to table below:

2. Measure and record the differential pressure across the

valve in the throttled position.

3. Locate percentage of valve opening on the bottom scale of

Flow Characteristic Curve (Fig. 6). Project line vertically up

to intersect with the Valve Characteristic Curve and from

this point project line horizontally across to the left of the

chart and record the percentage of maximum flow rate.

4. On the Series TDV Performance Curve (Fig. 5) locate the

differential pressure obtained in Step 6.3.2 and project line

horizontally across to intercept with Valve Performance

Curve. Drop a line vertically down to read the flow rate at

the bottom of the chart.

5. To calculate flow rate of valve in the throttled position, mul-

tiply the flow rate from Step 6.3.4 by the percentage flow

rate from Step 6.3.2 divided by 100.

Example: Valve size 4 in.

Differential Pressure in 5.4 ft. (1.65m)

Number of rings open = 3, 3 rings ÷ 6 rings x 100 =

50% throttled

• From the Performance Curve (Fig. 5), a 4 in. valve

with 5.4 ft. pressure drop (1.65m) represents a flow of

400 USgpm (25.2 l/s).

• From Flow Characteristic Curve (Fig. 6), a 4 in. valve,

50% open, represents 34% of maximum flow.

• Approximate flow of a 4 in. valve, with a 5.4 ft. (1.65m)

pressure drop when 50% throttled is:

400 x 34 = 136 USgpm

(25.2 x 34

= 8.57 l/s)

100

100

NOTE: To prevent premature valve failure it is not recommended

that the valve operate in the throttled position with more than

25 ft. pressure differential. Instead the pump impeller should be

trimmed or valves located else where in the system to partially

throttle the flow.

Operation

1. To assure tight shut off the valve must be closed using a

wrench with 25 to 30 ft./lbs. of torque.

2. To assure trouble-free check valve operation and shut off

operation, the valve should be periodically opened and

closed to keep valve seat and valve disc guide stem free of

build up of system contaminants.

3

Fig. 5

Pressure Drop (MH

2

O)

20

10

5.0

2.0

50

100

500

1000

2000 4000 6000

3.0

5.0

10

20

50

100 200

400

20

10

5.0

2.0

Flowrate (USGPM)

Pressure Drop (Ft.

WG)

Fig. 6

100

80

60

40

20

0

0

20

40

60

80

100

12”

8”

10”

6”

5”

4” 3”

2

1

⁄

2

”

Percent of Max Flow

Inherent Flow Characteristic Curve with Valve in Throttled Position

Series TDV Performance Curve with Valve in Full Open Position

Percent of Full Open

5

3

1

.5

Flowrate (L/Sec)

2

1

⁄

2

”

3”

4”

5”

6”

8”

10”

12”