Dimensions — weights – Watts MGH User Manual

Page 2

ES-G/GH/MG/MGH 0434

© Watts Regulator Co., 2004

Printed in U.S.A.

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.wattsreg.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscda.com

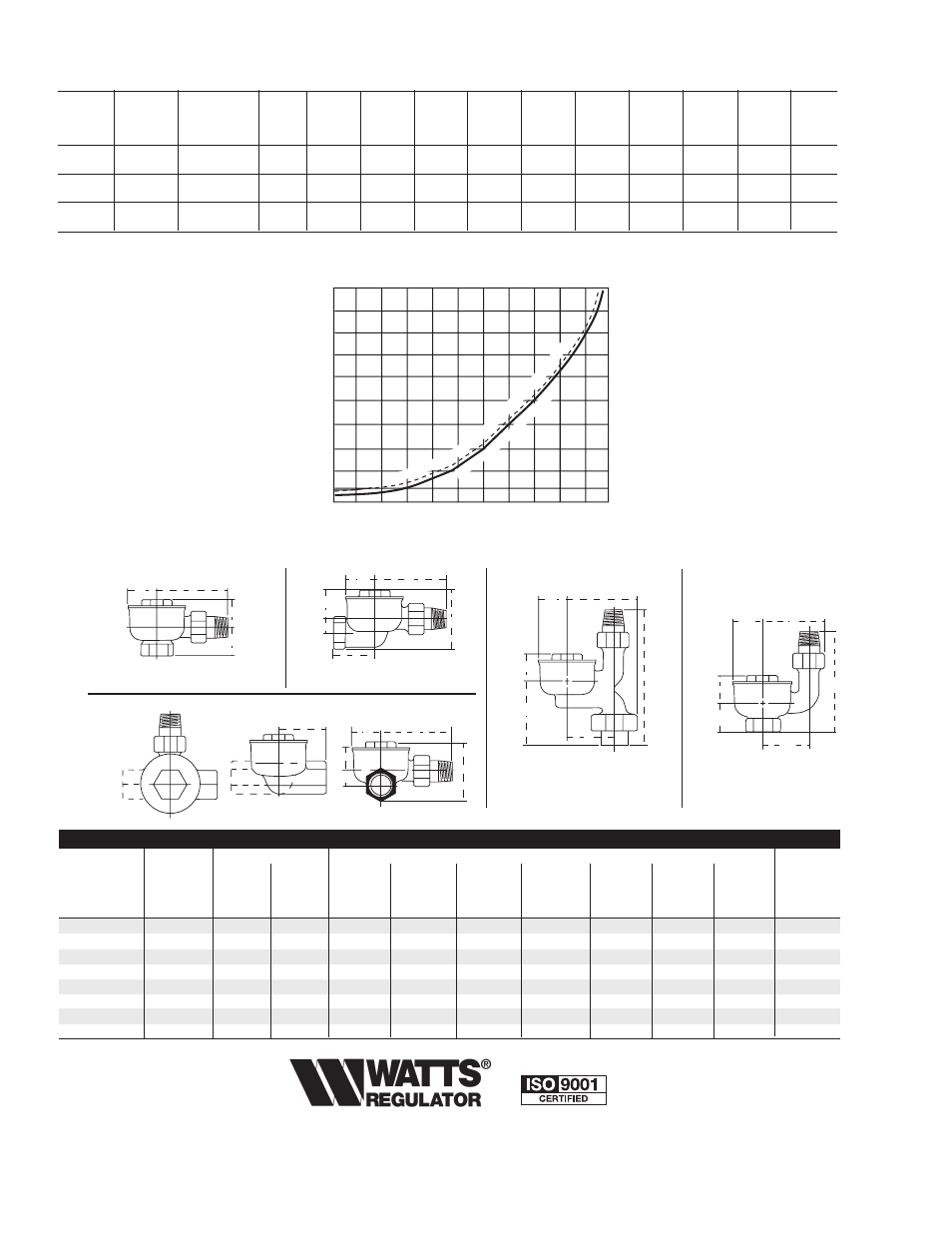

C

A

D

B

D

C

E

A

F

G

Angle Pattern

1GAP, 3GHAP, 5MGHAP

Straightway Pattern

1GHSW, 3GHSW

Corner Pattern

1GLHC, 1GRHC

- - - LEFT HAND

—— RIGHT HAND

Vertical Pattern

Double Union

1 VGDU

Vertical Pattern

Single Union

1VG

C

G

F

B

D

D

B

E

F

C

G

F

A

C

D

E

G

E

MODEL

PATTERNS

TAPPING

DIMENSIONS

WEIGHT

Male

Inlet

Outlet

Tailpiece

A

B

C

D

E

F

G

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

lbs.

kgs.

1GAP-1MGAP

Angle

1

⁄

2

15

1

⁄

2

15

2

7

⁄

8

73

1

1

⁄

8

29

1

3

⁄

16

35

1

3

⁄

8

35

–

–

–

–

–

–

1.2

.54

1GRHC-1GLHC

Corner

1

⁄

2

15

1

⁄

2

15

2

7

⁄

8

73

–

–

1

3

⁄

16

35

1

3

⁄

8

35

9

⁄

16

14

2

5

⁄

8

67

1

5

⁄

8

41

1.4

.64

1GSW-1MGSW

Straightway

1

⁄

2

15

1

⁄

2

15

2

7

⁄

8

73

–

–

1

3

⁄

16

35

1

3

⁄

8

35

9

⁄

16

14

2

5

⁄

8

67

1

5

⁄

8

41

1.2

.54

1VG

Vert. S.U.

1

⁄

2

15

1

⁄

2

15

–

–

1

1

⁄

8

29

1

3

⁄

16

35

1

3

⁄

8

35

1

7

⁄

8

48

4

102

2

5

⁄

8

67

1.4

.64

1VGDU

Vert. D.U.

1

⁄

2

15

1

⁄

2

15

–

–

2

9

⁄

16

65

1

3

⁄

16

35

1

3

⁄

8

35

1

7

⁄

8

48

5

3

⁄

8

137

2

3

⁄

4

70

1.7

.77

3GH-3MGH

Angle

3

⁄

4

20

3

⁄

4

20

3

1

⁄

8

79

1

3

⁄

8

35

1

3

⁄

16

35

1

5

⁄

8

41

–

–

–

–

–

–

1.5

.68

3GH-3MGH

Straight

3

⁄

4

20

3

⁄

4

20

3

1

⁄

8

79

–

–

1

3

⁄

16

35

1

9

⁄

16

40

3

⁄

8

10

2

3

⁄

4

70

1

7

⁄

8

48

1.5

.68

5MGH

Angle

1

25

1

25

3

5

⁄

8

92

1

1

⁄

2

38

1

1

⁄

2

38

1

11

⁄

16

43

–

–

–

–

–

–

2.5

1.13

Maximum Trap Capacities - Pounds condensate per hour, MBH, and square feet EDR

Pressure

Tapping

Differential

Model

(NPT)

(psi)

1

⁄

4

1

⁄

2

1

1

1

⁄

2

2

5

10

15

25

50

65

1G

Lbs. Cond

1 MG

1

⁄

2

"

Per Hour*

21.0

29.7

40.9

49.6

58.4

92.4

133.6

162.5

212.0

309.2

357.3

3GH

Lbs. Cond.

3MGH

3

⁄

4

"

Per Hour*

40.8

56.9

81.8

99.3

115.5

182.3

264.7

330.2

436.8

618.4

858.7

Lbs. Cond.

5MGH

1"

Per Hour*

71.8

101.5

143.8

173.7

201.2

319.7

463.9

584.0

688.7

789.5

820.0

* Ratings are in accordance with the recommended standards adopted by the Steam Heating Equipment Manufacturers Association. Select trap directly

from table for the lowest differential that may exist in the system. Traps may be applied directly and no safety factor need by applied.

St

ea

m

Pr

es

su

re

- T

em

pe

ra

tu

re

Cu

rv

e

Bala

nce

d In

tern

al P

re

ss

ur

e -

Te

m

pe

ra

tu

re

Cu

rv

e

of

Th

er

m

os

ta

tic

D

ia

ph

ra

gm

100

120

160

140

180

200

220

240

260

280

300 320

70

60

50

40

30

20

10

0

10

20

Temperature – Degrees F.

Pressure – PSIG

Vacuum – In., HG.

Dimensions — Weights