Materials, Pressure - temperature, Installations – Watts 800M4FR User Manual

Page 2: Dimensions – weights standards, Approvals, Notice

Materials

Springs

Stainless Steel

Bonnet

Celcon

Vent Disc

Silicone Rubber

Disc Holder Float Polypropylene

Check Valve Disc Silicone Rubber

Check Valve Seat Noryl Plastic

Body Bronze

Pressure - Temperature

Temperature Range: 33°F to 140° (1°C to 60°C)

Maximum Working Pressure: 150psi (10.3 bar)

Installations

This valve is designed for installation in a continuous pressure

potable water supply system 12” above the highest point of the

downstream piping. The valve must be installed with the supply

connected to the bottom and in a vertical position. Allow adequate

space for periodic inspection, servicing or testing. The valve should

not be installed in an area where freezing or spillage will cause

damage. Adequate drainage/freeze protection must be provided in

cold weather applications. 1.5psi (.10 bar) must be exerted against

the float spring to seal the float and air inlet. Do not undersize sup-

ply and discharge piping.

Vacuum breakers are not desiged, tested or

approved to protect against backpressure backflow or water ham-

mer shock. For protection against backpressure backflow, install

Watts 909/009 Reduced Pressure Zone Backflow Preventer. For

Protection against water hammer shock install a Watts Series 15

Water Hammer Arrestor utilizing good plumbing practice.

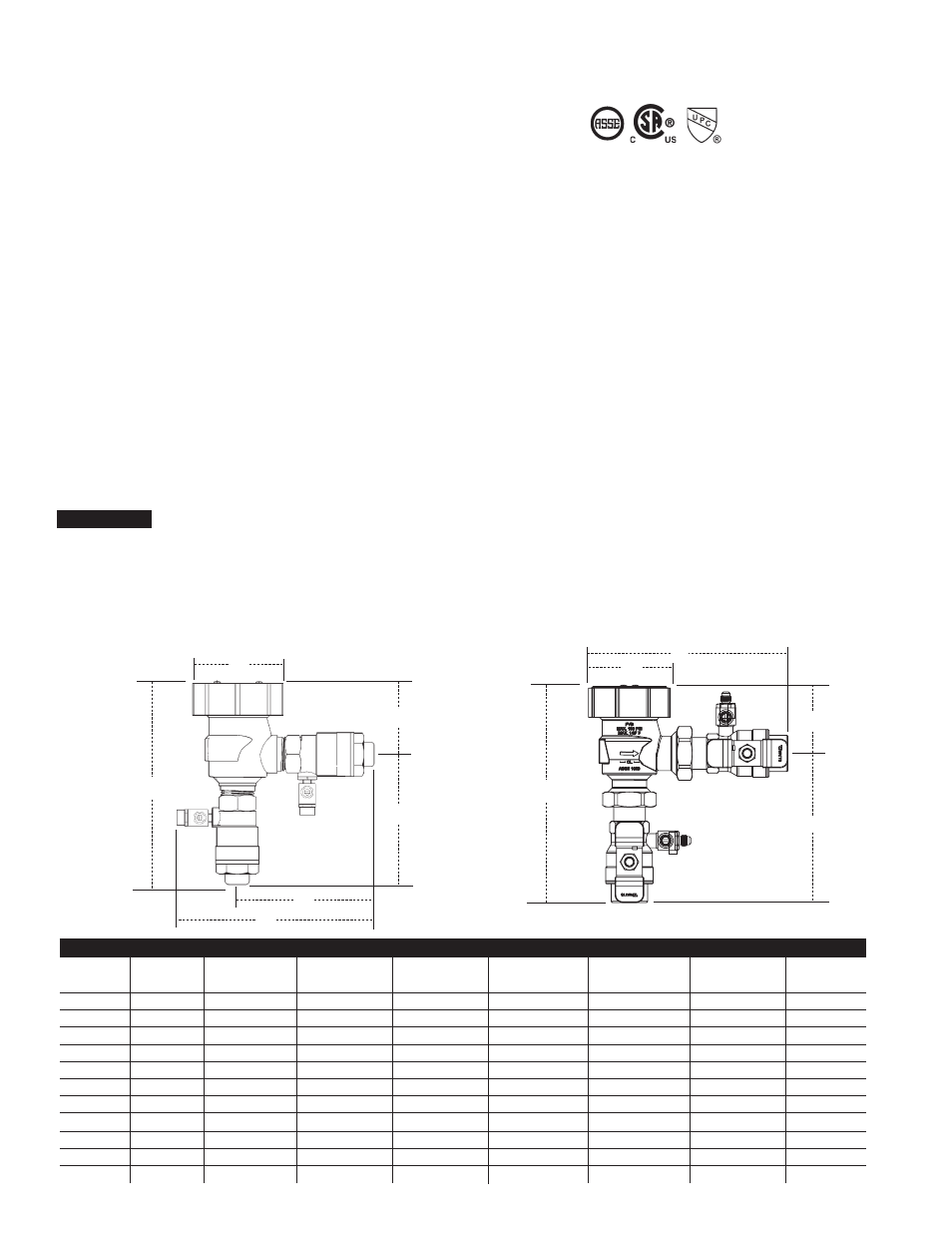

Dimensions – Weights

Standards

ANSI, IAPMO, USC Manual Section 10

Approvals

IAPMO

Approved by the foundation for Cross-Connection Control and

Hydraulic Research at the University of Southern California,

Manual Section 10. QC models are not ASSE 1020 approved.

1020

B64.12

C

D

A

G

B

U800M4FR

D

C

E

A

G

B

800M4FR

moDEl

SizE (DN)

DimENSioNS

WEiGht

A B C D E G

in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kg.

800M4FR

1

⁄

2

15 6

1

⁄

8

156 6

1

⁄

4

159 2

9

⁄

16

65 3

11

⁄

16

94 3

7

⁄

8

98 2

1

⁄

4

57 4 1.8

800M4FR

3

⁄

4

20 6

1

⁄

2

165 6

1

⁄

2

165 2

9

⁄

16

65 3

15

⁄

16

100 4

1

⁄

8

105 2

1

⁄

4

57 4 1.8

800M4FR 1 25 7

1

⁄

2

191 7

1

⁄

2

191 2

3

⁄

4

70 4

3

⁄

4

121 4

7

⁄

8

124 3

7

⁄

16

87 6 2.7

800M4FR 1

1

⁄

4

32 8

7

⁄

8

225

9 229 3

1

⁄

4

83 5

3

⁄

4

146 6

1

⁄

8

156

5 127 11 5.0

800M4FR 1

1

⁄

2

40 9

1

⁄

4

235 9

1

⁄

2

241 3

1

⁄

4

83 6

1

⁄

4

159 6

3

⁄

8

162

5 127 14 6.3

800M4FR 2 50 10

5

⁄

8

270 9

5

⁄

8

245 3

1

⁄

4

83 6

3

⁄

8

162 7 178

5 127 19 8.6

U800M4FR

3

⁄

4

20 6

3

⁄

8

163 7

9

⁄

16

192 2

1

⁄

8

55 5

7

⁄

16

138 – – 2

1

⁄

4

57 4 1.8

U800M4FR 1 25 8

5

⁄

16

211

9 229 2

13

⁄

16

71 6

3

⁄

16

158 – – 3

7

⁄

16

87 6 2.7

800M4FRQC

1

⁄

2

15

7

7

⁄

8

199

8 203 2

13

⁄

16

71

5

7

⁄

16

138

5

5

⁄

8

144

3

7

⁄

16

87

4.5 2.0

800M4FRQC

3

⁄

4

20

8

1

⁄

2

216 8

1

⁄

2

216

2

13

⁄

16

71

5

11

⁄

16

144

6

1

⁄

8

156

3

7

⁄

16

87

4.7 2.1

800M4FRQC 1 25 9

1

⁄

2

241

9

1

⁄

2

241

2

13

⁄

16

71

6

3

⁄

4

171

6

7

⁄

8

175

3

7

⁄

16

87

6.6 3.0

NOTICE