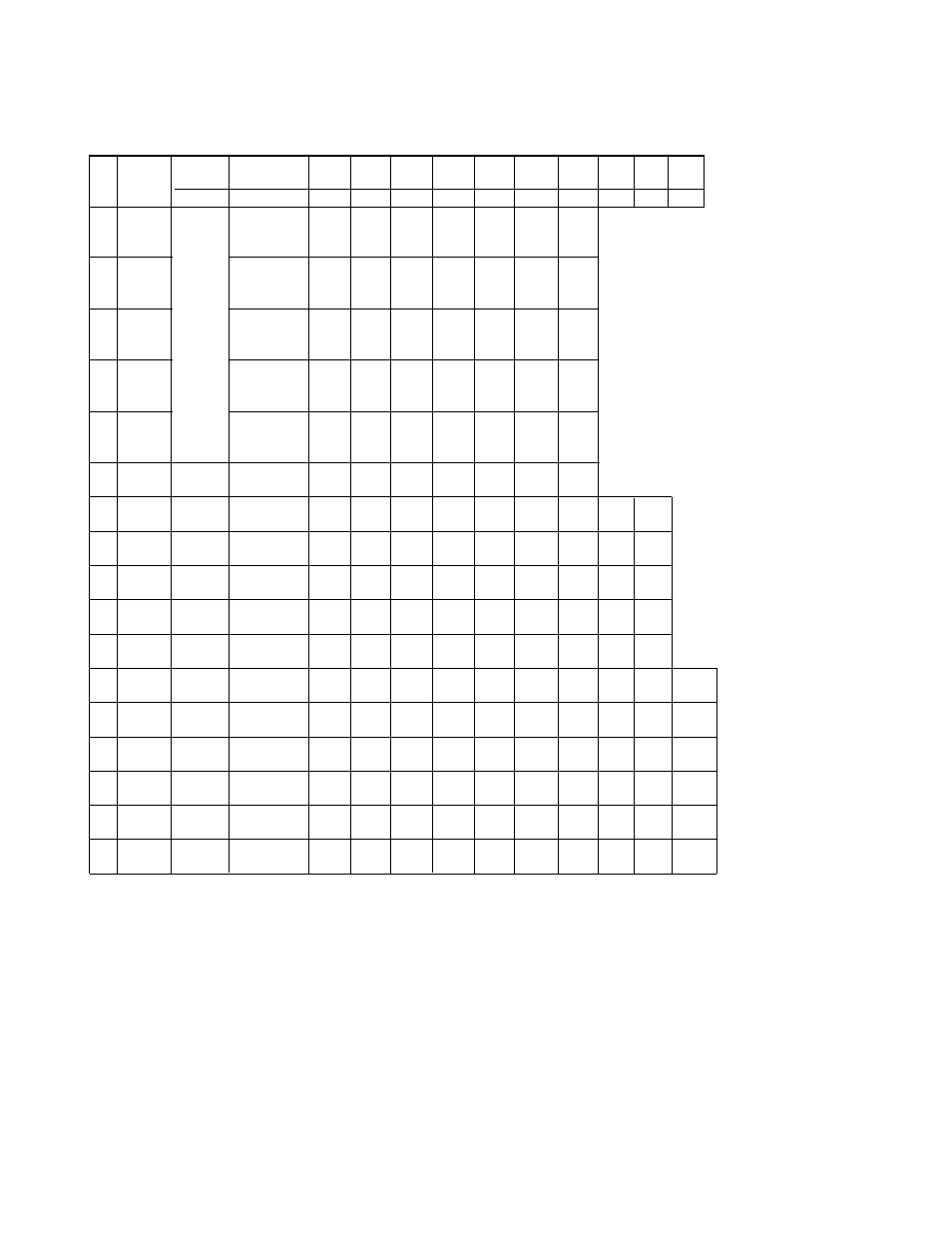

Maximum trap capacities – Watts MG User Manual

Page 3

Valve Seat

Pressure

1

⁄

4

1

⁄

2

1

2

5

10

15

20

30

50

Orifice

Differential

Size Model

Diameter

Lat. Ht. Value

969.8

969.3

968

966

961

952

945

939

929

912

Lbs. Cond./Hr.

70

100

140

200

210

220

230

3

⁄

4

6G-15

MBH

68

97

136

193

202

209

217

EDR

282

404

566

804

841

870

904

Lbs. Cond./Hr.

175

250

350

500

525

550

575

1

7G-15

MBH

170

242

339

483

505

524

543

EDR

708

1008

1413

2012

2104

2183

2263

Lbs. Cond./Hr.

425

600

850

1200

1260

1320

1280

1

1

⁄

4

8G-15

MBH

412

582

823

1159

1211

1257

1304

EDR

1717

2423

3428

4830

5045

5236

5434

Lbs. Cond./Hr.

850

1200

1700

2400

2520

2640

2760

1

1

⁄

2

91G-15

MBH

824

1163

1646

2318

2422

2513

2608

EDR

3435

4847

6857

9660

10091

10472

10868

Lbs. Cond./Hr.

1775

2500

3550

5000

5250

5500

5750

2

101G-15

MBH

1721

2423

3436

4830

5045

5236

5434

EDR

7172

10096

14318

20125

21021

21817

22641

2

111MG-15

21

⁄

32

Lbs. Cond./Hr.

2200

2900

3920

5200

7600

10100

12000

MBH

2133

2811

3795

5023

7304

9615

11340

1

7MG-30

1

⁄

8

Lbs. Cond./Hr.

95

127

170

228

335

445

530

600

700

MBH

92

123

165

220

322

424

501

563

650

1

1

⁄

4

8MG-30

5

⁄

32

Lbs. Cond./Hr.

156

210

280

375

550

740

870

980

1160

MBH

151

204

271

362

529

704

822

920

1078

1

1

⁄

2

91MG-30

19

⁄

64

Lbs. Cond./Hr.

525

700

940

1250

1850

2450

2930

3300

3900

MBH

509

679

910

1208

1778

2332

2769

3099

3623

2

101MG-30

11

⁄

32

Lbs. Cond./Hr.

670

890

1180

1580

2340

3120

3700

4150

4900

MBH

650

863

1142

1526

2249

2970

3497

3897

4552

2

111MG-30

15

⁄

32

Lbs. Cond./Hr.

1300

1750

2340

3120

4600

6100

7200

8200

9700

MBH

1261

1696

2265

3014

4421

5807

6804

7700

9011

3

⁄

4

6MG-50

3

⁄

32

Lbs. Cond./Hr.

52

69

92

122

180

240

285

320

380

470

MBH

50

67

89

118

173

228

269

300

353

429

1

7MG-50

7

⁄

64

Lbs. Cond./Hr.

81

108

143

190

280

375

440

500

590

730

MBH

79

105

138

184

269

357

416

470

548

666

1

1

⁄

4

8MG-50

1

⁄

8

Lbs. Cond./Hr.

102

138

182

245

355

475

565

630

750

920

MBH

99

134

176

237

341

452

534

591

697

839

1

1

⁄

2

91MG-50

15

⁄

64

Lbs. Cond./Hr.

360

480

640

860

1260

1680

2000

2250

2670

3300

MBH

349

465

620

831

1211

1599

1890

2113

2480

3010

2

101MG-50

9

⁄

32

Lbs. Cond./Hr.

460

610

820

1100

1600

2140

2520

2841

3350

4150

MBH

446

591

794

1063

1538

2037

2381

2667

3112

3785

2

111MG-50

21

⁄

64

Lbs. Cond./Hr.

630

850

1140

1520

2220

2950

3500

3950

4700

5800

MBH

611

824

1104

1468

2133

2808

3308

3709

4366

5290

The basic capacity ratings are expressed in pounds conden-

sate per hour at various pressure differentials.

For ease of trap selection the tables also give the heating

value in MBH of the steam condensed. This is arrived at by

multiplying the condensate rating by the appropriate Latent

Heat Value and dividing by 1,000 to determine MBH.

Capacities are also expressed in square feet Equivalent

Direct Radiation. This is determined by dividing the heating

capacity in BTU/Hr. (MBH x 1,000) by 240 BTU/Hr./Square

Foot Equivalent Direct Radiation.

Example:

Select a trap for a Unit Heater with a heating capacity of 170

MBH operating on a 5 psi line. A 2 to 1 capacity factor is desired.

MBH rating for selection purposes =

2 x 170 = 340 MBH. Read down 5 psi

column and select the smallest trap whose

MBH rating exceeds 340 MBH.

The 1" 7G has a capacity of 505 MBH,

or 525 pounds of condensate per hour on

2,104 square feet Equivalent Direct

Radiation. 1" 7G is the correct trap for

this application.

Note: The condensate capacities for GF or MGF traps are the same as shown for G or MG float and thermostatic traps and selection should

be made in the same manner.

**Ratings are in accordance with the recommended standards adopted by the Steam Heating Equipment Manufacturers Association. Select trap directly from

table for the lowest differential that may exist in the system. Traps may be applied directly and no safety factor need be applied.

Maximum Trap Capacities

Pounds Condensate Per Hour, MBH, and Square Feet EDR

**Ca

pacities According

to

Recommended Shema Standards