System start-up, Vii. system start-up – Burnham LEDV SERIES User Manual

Page 22

22

VII. System Start-up

A.

ALWAYS INSPECT INSTALLATION BEFORE

STARTING BURNER.

B

. FILL HEATING SYSTEM WITH WATER. Refer to

Section III, G.

C.

CHECK CONTROLS, WIRING AND BURNER to be

sure that all connections are tight and burner is rigid,

that all electrical connections have been completed and

fuses installed, and that oil tank is filled and oil lines

have been tested.

D

. LUBRICATION — Follow instruction on burner and

circulator label to lubricate, if oil lubricated. Most

motors currently used on residential type burners

employ permanently lubricated bearings and thus do

not require any field lubrication. Water lubricated

circulators do not need field lubrication.

Do not over-lubricate. This can cause as much trouble

as no lubrication at all.

E

. SET CONTROLS with burner service switch turned

“OFF”.

1. SET ROOM THERMOSTAT about 10° above

room temperature.

2. PRESS RED RESET BUTTON on R8184P Oil

Primary Control and release.

3. Set high limit dial on L8148 at temperature to suit

requirements of installation.

F

.

BURNER START-UP

1. VERIFY burner settings.

a. Refer to Table 4.

2. Open all shut-off valves in the oil supply line to the

burner.

3. Attach a plastic hose to fuel pump vent fitting and

provide a container to catch the oil.

4. REMOVE GAUGE PORT PLUG from fuel pump

and install pressure gauge.

5. REMOVE TEST PLUG IN FLUE COLLAR.

6. Close the service switch to start the burner. If the

burner does not start immediately, check the

manual overload switch on the motor, if so

equipped, and the safety switch of the burner

primary control.

WARNING

All boilers equipped with burner swing door have a potential hazard w hich can cause severe

property damage, personal injury or loss of life if ignored. Before opening swing door, turn off

service switch to boiler to prevent accidental firing of burner outside the combustion chamber.

Be sure to tighten swing door fastener completely when service is completed.

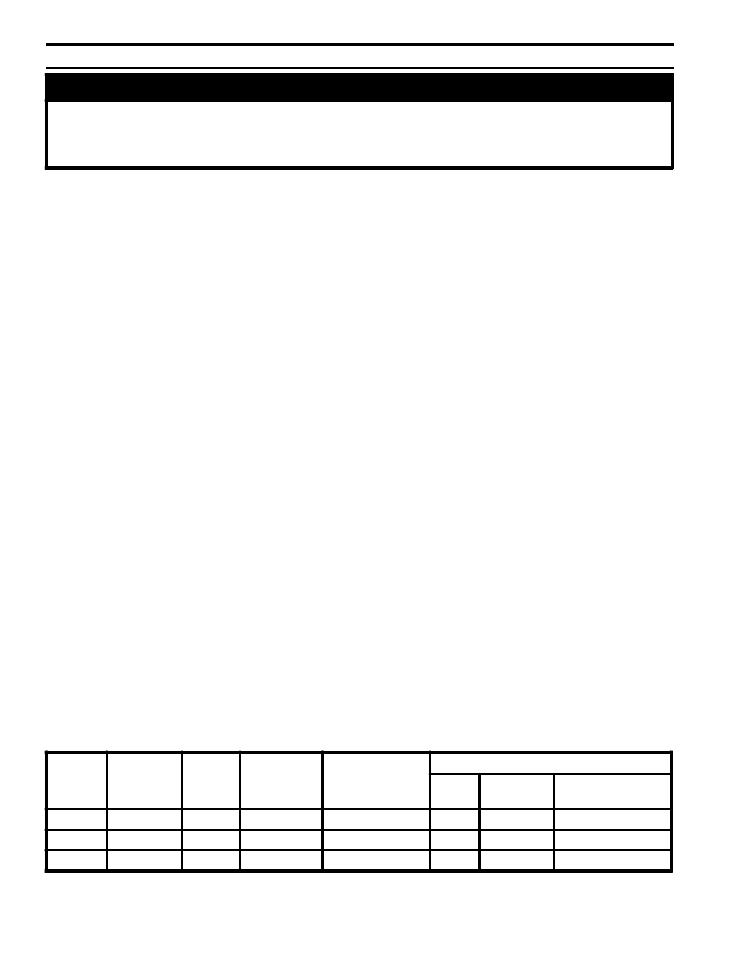

TA B LE 4 : BE C K ETT A FII B U R N ER

Boiler

Model

F iring Rate

(GPH)

Burner

Air Tube

Com bi nati on

Delavan Nozzle

Setti ngs

A ir

Head

( stop s cr ew)

Pump Pr essu re

(P SIG)

LEDV -1

0.60

AFII 85

HLX 50HD

0.50 x 70° B

2.5

#2

140

LEDV -2

1.00

AFII 150

HLX5 0HE

0.85 x 60° B

3.5

#3

140

LEDV -3

1.25

AFII 150

HLX5 0HE

1.00 x 60° B

4.0

#5

140