Bendix Commercial Vehicle Systems EverSure Spring Brake with No Touch Technology User Manual

Page 3

3

The diaphragm is held between the adapter base and non-

pressure plate by a two piece clamp ring.

Different size brake chambers are identified by numbers,

which specify the effective area of a diaphragm. For

example, a Type 30/30 Spring Brake has 30 square inches

of effective area on each diaphragm.

The standard diaphragm material is a compound of natural

rubber with a fabric interior of nylon.

WARNING!

• Spring brake chambers contain a loaded

compression spring. Property damage, serious

injury or death may occur if instructions are not

followed completely.

• When performing any maintenance on the spring

brakes, make sure to block the wheels to prevent

vehicle rollaway.

• DO NOT SERVICE A SPRING BRAKE CHAMBER

IF IT HAS STRUCTURAL DAMAGE OF ANY KIND.

Replace the complete assembly. Dismount a

damaged spring brake by first cutting the service

push rod with an acetylene torch to relieve any

force it might have.

• Do not strike any part of a spring brake chamber

for any reason. This may cause structural damage.

• Be careful not to drop a spring brake chamber at

any time. If dropped, inspect for signs of structural

damage. Replace complete assembly if damaged.

• Spring brake chambers cannot have the emergency

diaphragm replaced. Replace the whole spring

brake chamber.

• Always work from the side of the spring brake

chamber. Never work from the front or back.

3. PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended

warranty may be voided if intrusive maintenance is

performed during this period.

Because no two vehicles operate under identical conditions,

maintenance intervals will vary. Experience is a valuable

guide in determining the best maintenance interval for a

vehicle.

3.1. EVERY 300 OPERATING HOURS,

8,000 MILES, OR ONE (1) MONTH:

3.1.1. See Figure 2. Check push rod travel and adjust

travel at the slack adjuster if needed (only where manual

slack adjusters are used). Push rod travel should be as

short as possible without the brakes dragging (consult

the manufacturer’s installation instructions for the slack

adjuster. Excessive push rod travel reduces braking

efficiency, shortens diaphragm life, gives slow braking

response, and wastes air.

3.1.2. Check push-rod-to-slack-adjuster alignment from

release to full stroke position to be sure the push rod

moves out and returns properly without binding at the non-

pressure plate hole or with other structures. Also, check

the angle formed by the slack adjuster arm and push rod.

It should be greater than 90 degrees when the chamber

is in the released position and approach 90 degrees at

maximum readjustment stroke.

3.1.3. Check tightness of mounting nuts. Torque on the

non-pressure plate mounting nuts should be 133-155 ft/

lbs.

3.1.4. Check cotter pins to ensure they are in place.

3.1.5. Check all hoses and lines. They should be secure

and in good condition with sufficient length to allow for axle

movement.

3.2. EVERY 3,600 OPERATING HOURS,

100,000 MILES OR ONE (1) YEAR:

3.2.1. Carefully inspect all metal parts for cracks, distortion

or damage.

3.2.2. Perform the Leakage Test (4.2). As necessary,

install a new diaphragm or any other parts if they are worn

or deteriorated. All diaphragm sealing surfaces should

be smooth and clean. Perform the steps outlined in

"12. Replacing the Service Diaphragm". When the service

diaphragm, service return spring, or both are replaced, they

should also be replaced in the corresponding chamber on

the same axle.

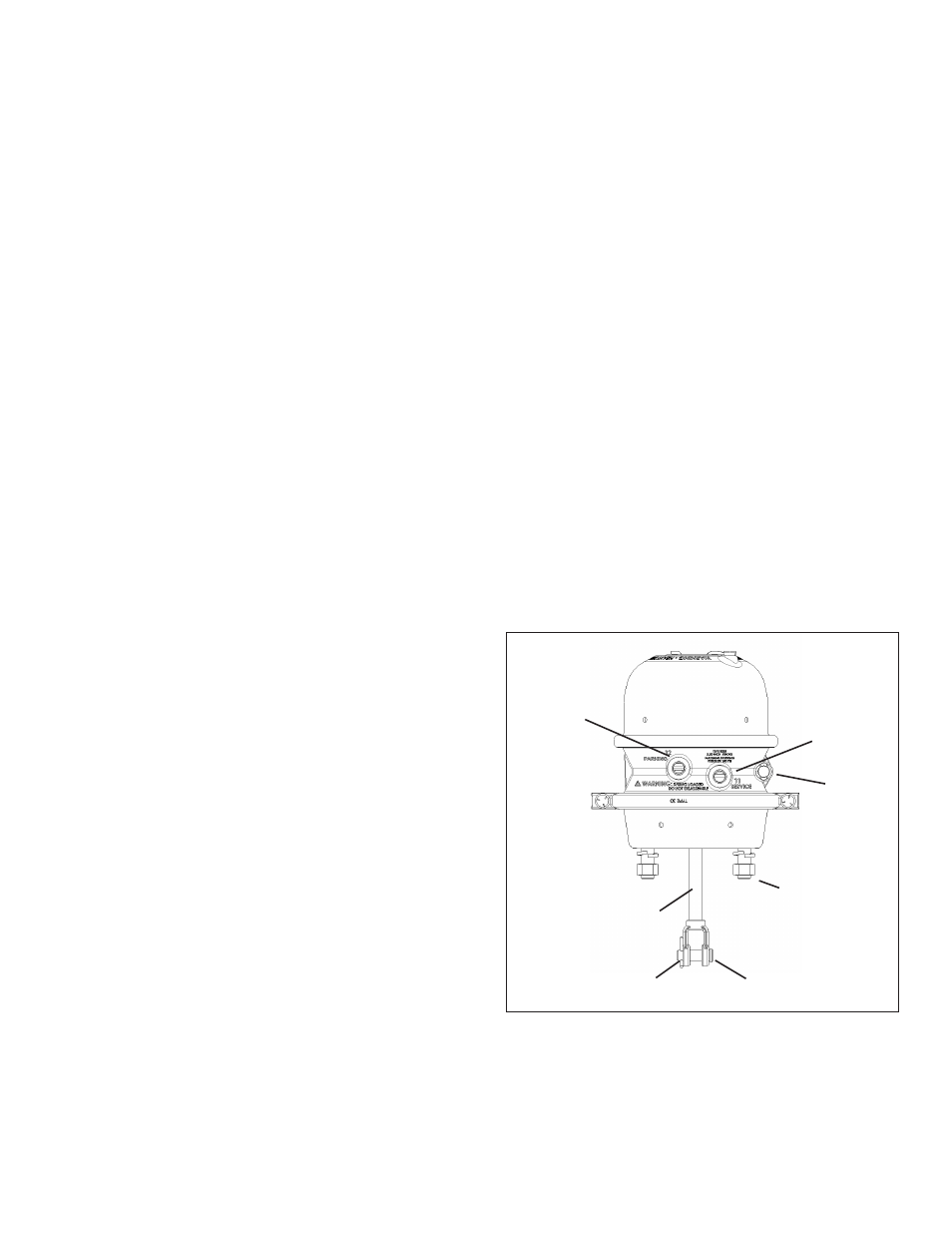

RELEASE

TOOL

SIDE

PARKING/

EMERGENCY

PORT

SERVICE

PORT

MOUNTING NUT

COTTER PIN

YOKE

SERVICE

PUSH ROD

FIGURE 2 - SPRING BRAKE EXTERNAL VIEW