Bendix Commercial Vehicle Systems Vertical and Lateral Alignment of Bendix Radar Sensors User Manual

Page 5

5

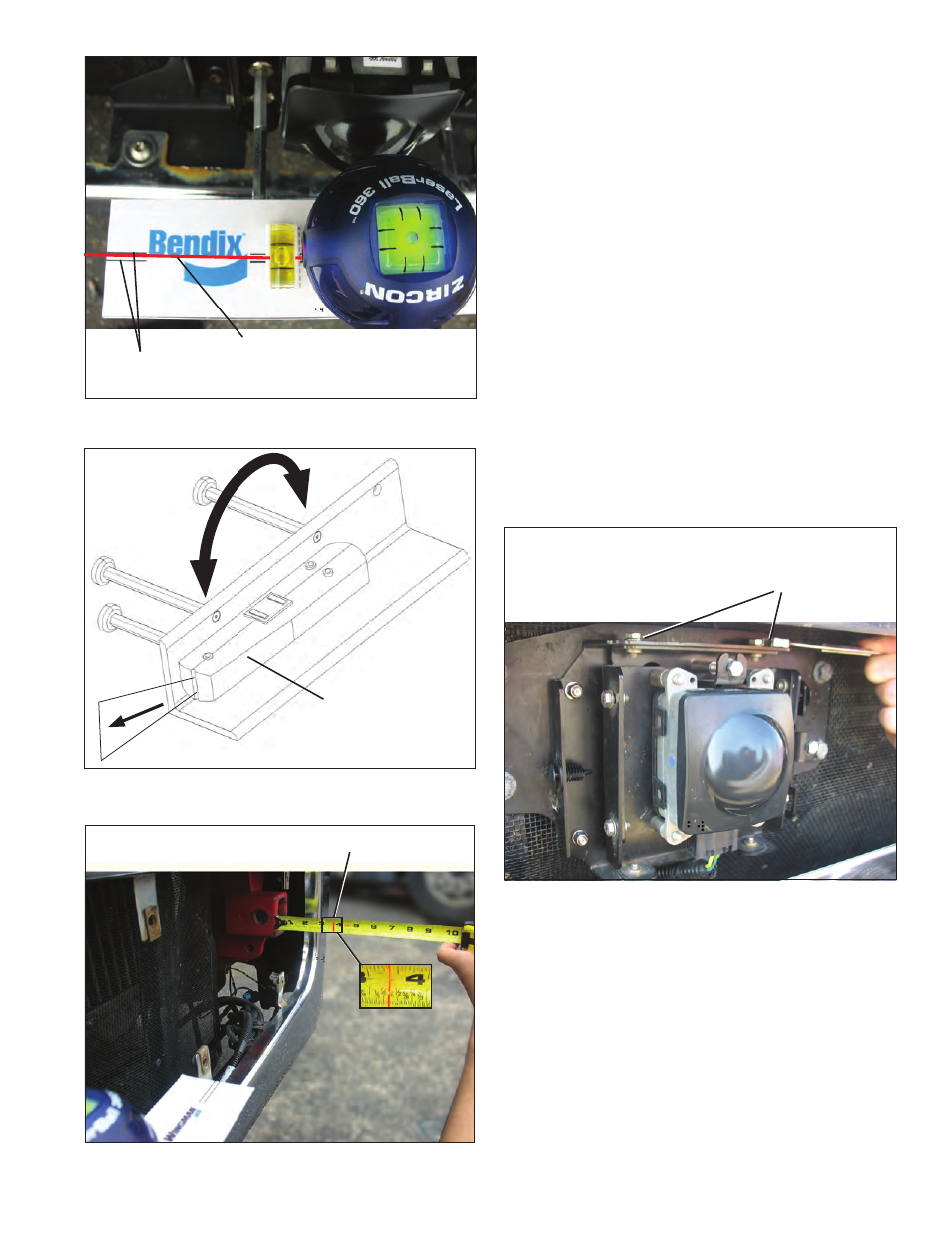

FIGURE 33 - POSITIONING THE LASER LEVEL (KITS

K041451 OR K041227)

Laser Light

Beam

Beam

Reference Lines

FIGURE 34 - USING THE LATERAL ALIGNMENT LEVEL

(KIT K065284)

Lateral Alignment

Laser

Laser

Light Beam

The Whole

Tool is

Reversed for

the Second

Measurement

FIGURE 35 - LATERAL ALIGNMENT VERIFICATION

Laser Light Line

NOTE: The lateral alignment also can be checked with

Bendix ACom

®

Diagnostics (version 6.3 or higher). A

value between -0.8° and 0.8 ° is acceptable and the

system should operate normally. A value between

-0.8° to -1.3° OR 0.8° to 1.3° means the radar sensor is

misaligned and system performance will be degraded.

The service technician should align the radar sensor

using the procedures noted in this section.

If the value is less than (<) -1.3°, or greater than

(>) 1.3°, the system will typically issue a Diagnostic

Trouble Code. The service technician should align

the radar sensor laterally. A positive value means the

radar sensor should be aligned toward the driver side.

A negative value means the radar sensor should be

aligned towards the passenger side. The vehicle must

be driven at least 20 miles between adjustments. See

“Alignment Value” in Figure 17.

6.10 LATERAL ADJUSTMENT PROCEDURE

NOTE: Complete these steps only if a vertical adjustment

is necessary.

1. Loosen the four lateral position screws. DO NOT fully

remove them. See Figure 36.

Four Lateral Position Screws

[Two (2) on the top and two (2) on the bottom]

Loosen - Do Not Remove

FIGURE 36 - LATERAL POSITION SCREWS