Bendix Commercial Vehicle Systems Vertical and Lateral Alignment of Bendix Radar Sensors User Manual

Page 3

3

Magnetic

Attachments

Lateral Alignment

Laser Level

Radar Sensor

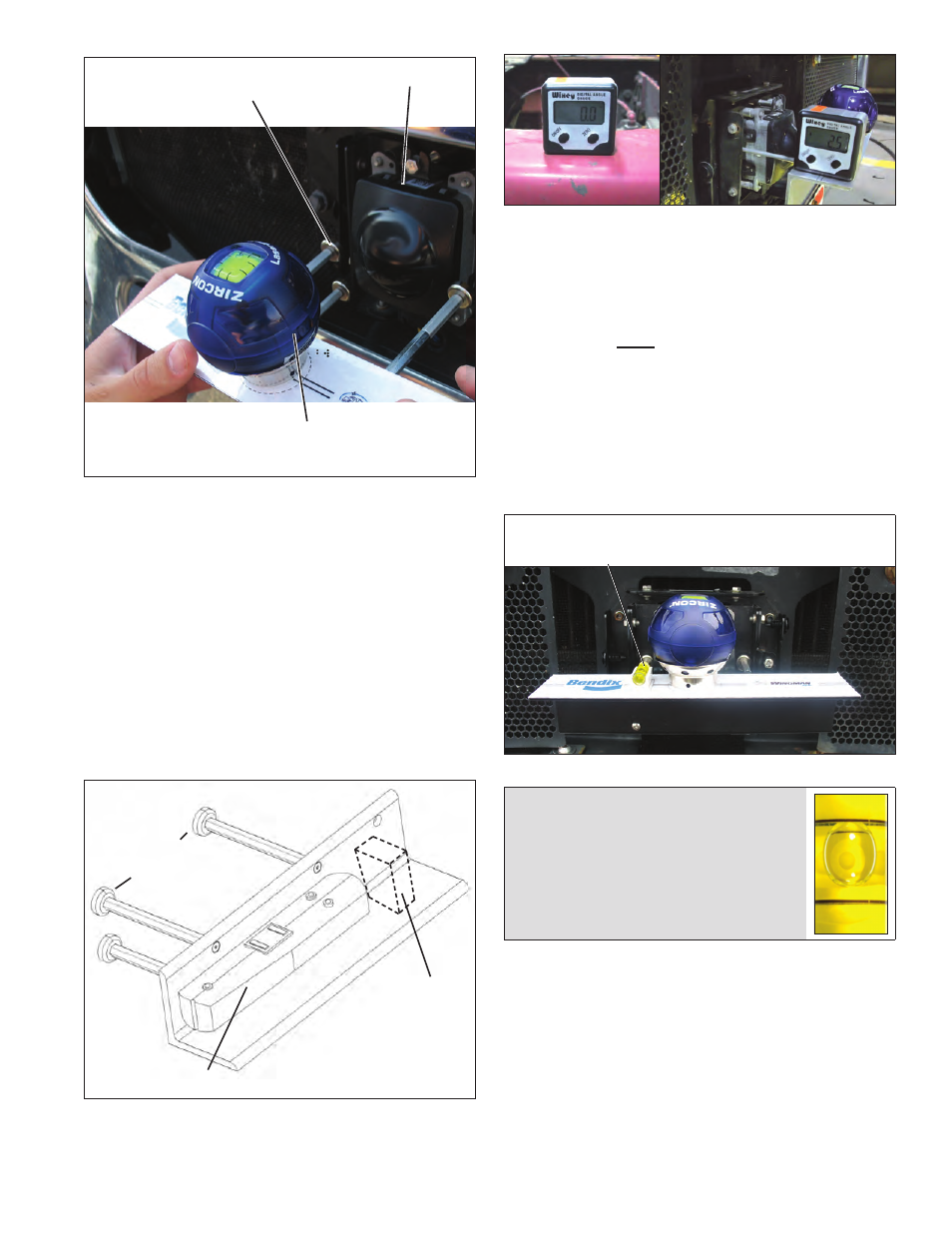

FIGURE 27 - ATTACHING THE ALIGNMENT TOOL (SHOWS

TOOL K041451 OR K041227)

6.07.5

Check the vertical Alignment.

Using the standard tool K065284. With the air

suspension charged and set to “level”, calibrate (“zero”)

the inclinometer on a horizontal section of the frame rail.

Follow the manufacturer’s instructions (typically digital

inclinometers have a “SET” button for this purpose).

Check the alignment with the alignment tool in position

so that it straddles the radar sensor. Verify that the

radar alignment is within the range of -0.5° to -2.0°

(downward) when measured by an inclinometer set to

zero on the vehicle’s frame. If the sensor is not aligned

correctly, follow the instructions in section 6.08.

Lateral Alignment Laser

Typical Location

for Digital

Inclinometer

(Preferred

Method)

Magnetic

Attachments (3)

FIGURE 28 - VERTICAL ALIGNMENT TOOL (K065284)

FIGURE 29 - INCLINOMETER

6.07.6

If you have the original design of alignment

tool K041451 or K041227 (See Figure 26):

Where a digital inclinometer is available — or if a flat,

level location is not available (in which case a digital

inclinometer must be used) — do not use the bubble

level. Verify that the ACB sensor alignment is within

the range of -0.5° to -2.0° (downward) when measured

by an inclinometer set to zero on the vehicle’s frame.

Where the bubble-level may be used, verify that the

bubble just touches the line nearest the vehicle. This

shows that an incline of approximately one half of a

degree downward has been set. See Figure 31.

Vertical Alignment

Bubble Level

FIGURE 30 - VERTICAL ALIGNMENT BUBBLE LEVEL

Ideal bubble position - just touching the

line nearest to the vehicle.

FIGURE 31 - USING THE BUBBLE POSITION TO CHECK

THE VERTICAL ALIGNMENT (VEHICLE ON LEVEL GROUND)

If the sensor is not aligned correctly, follow the

instructions in section 6.0.8