Bendix Commercial Vehicle Systems AD-IS EVERFLOW ASSEMBLY User Manual

Page 8

8

CLEANING & INSPECTION

Consult the service data sheet for the dryer used in your

AD-IS

®

EverFlow

™

assembly. The service data sheet

contains information useful for maintenance and service

of the air dryers.

1. Use a suitable solvent to clean all metal parts, and

use a cotton swab to clean the bore (Note: Do not use

abrasives or tools to clean the bore: any scratches

caused may necessitate replacing the AD-IS

®

air

dryer.) Superfi cial external corrosion and/or pitting is

acceptable.

2. Clean the o-rings with a clean dry cloth. Do not use

solvents.

3. Inspect for physical damage to the bore and the check

valve seat. If the bore is damaged (by scratches etc.

that would prevent delivery check valve from seating),

replace the AD-IS

®

air dryer.

4. Inspect the delivery check valve, o-rings, etc. for wear

or damage. Replace if necessary using the check valve

replacement kit available at authorized Bendix parts

outlets.

5. Inspect all air line fi ttings for corrosion and replace as

necessary.

Guidelines outlined on pages 5-6 in this document. Also,

always depressurize the air dryer purge reservoir before

servicing the air dryer.

This procedure does not require removal of the AD-IS

®

air

dryer from the vehicle.

1. Remove the line from governor and mark for easy

reinstallation.

2. Remove the bolts attaching the governor to the AD-IS

®

air dryer and retain for reassembly.

3. Remove the governor from the air dryer. Be aware that

a short puff of trapped air may vent when the governor is

removed. Retain the governor gasket for reassembly if

a new governor gasket is not available. Remove and

retain the o-ring from the adapter.

4. The spring/delivery check valve can now be removed.

A second delivery check valve is located in the dryer

without a governor. This check valve is located behind a

hex head plug near the control line from the EverFlow

™

module to the air dryer. Carefully remove the hex plug

and follow the instructions that follow.

5. Remove and retain the o-ring from check valve body.

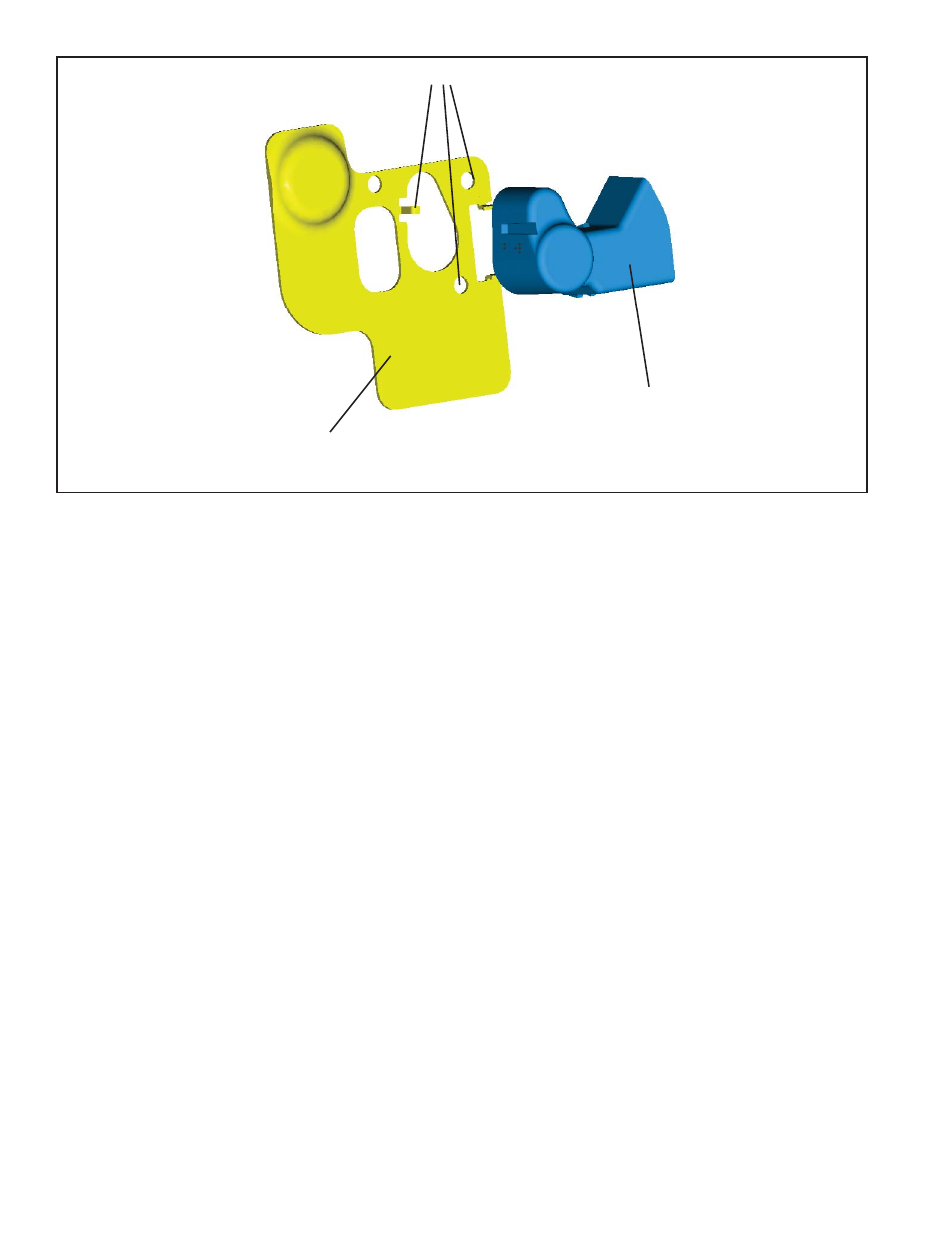

FIGURE 5 - SPLASH SHIELD BRACKET AND COVER - (EXPLODED VIEW)

SPLASH

SHIELD

BRACKET

SPLASH

SHIELD

COVER

LOCK TABS