Bendix Commercial Vehicle Systems AD-IS EVERFLOW ASSEMBLY User Manual

Page 3

3

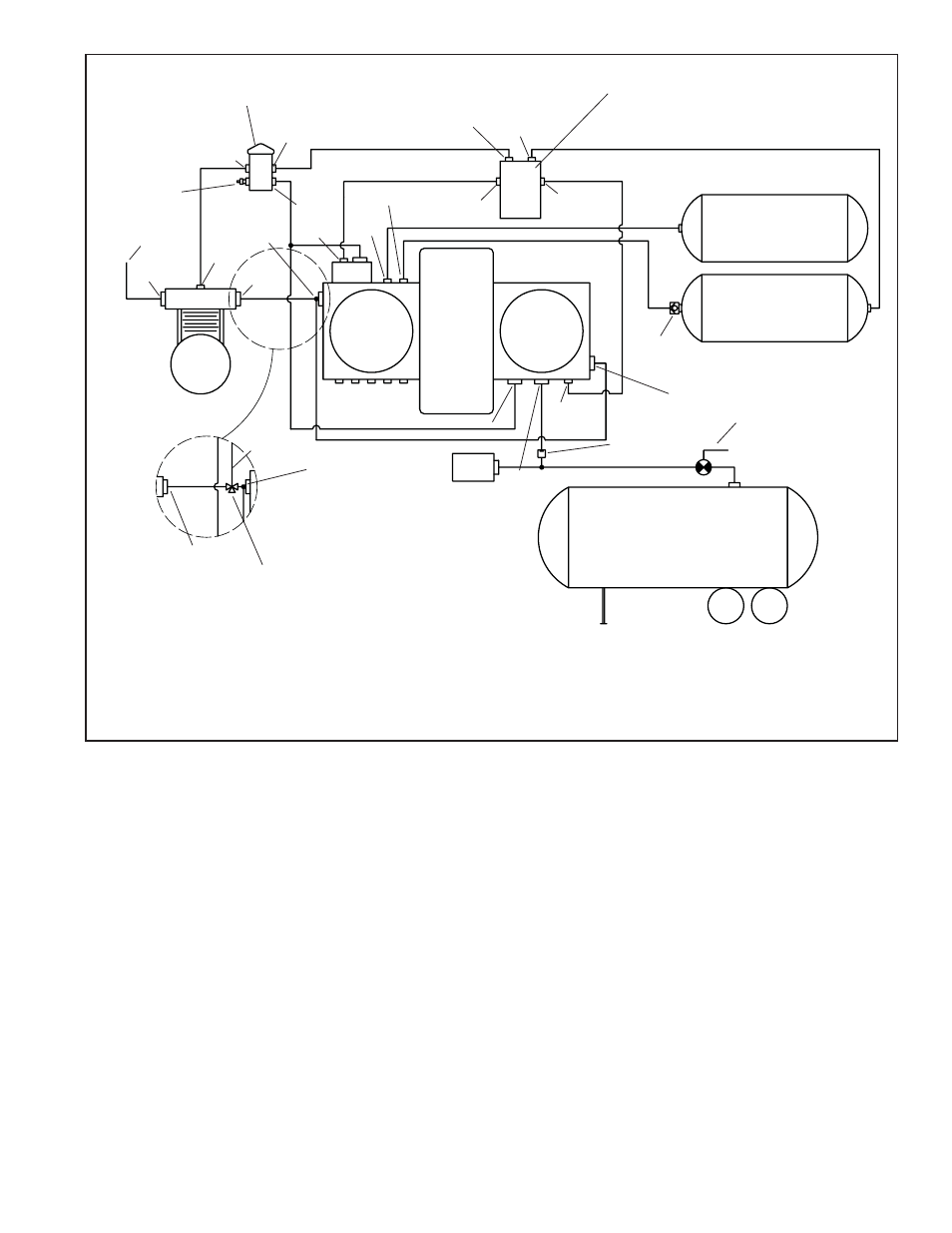

FIGURE 2 - AD-IS

®

AIR DRYER SYSTEM SCHEMATIC

charge cycle until the air brake system pressure builds

to the governor cut-out setting of approximately 130 p.s.i.

When air brake system pressure reaches the cut-out setting

of the governor, the governor unloads the compressor

and the electronic module sends a signal to one of the air

dryers to purge. The governor unloads the compressor by

allowing air pressure to fi ll the line leading to the compressor

unloader mechanism - causing the delivery of compressed

air to the AD-IS

®

EverFlow

™

assembly to be suspended.

Similarly, the governor also supplies air pressure to the

EverFlow

™

electronic module. The electronic module uses

this signal to determine the volume of air into the brake

system. If the volume is normal, the electronic module

sends a signal to the control port on the proper dryer. If the

volume is high, the electronic module switches the dryers

every 30 seconds until the air volume returns to normal.

The air dryer purge piston moves down in response to a

pneumatic signal from the EverFlow

™

electronic module,

causing the purge valve to open to the atmosphere and

Air then fl ows into the desiccant drying bed and becomes

progressively drier as water vapor adheres to the desiccant

material in a process known as “ADSORPTION.” Dry air

exits the desiccant cartridge through the delivery check

valve and also through an orifi ce into the purge reservoir.

The delivery check valve opens, supplying air to pressurize

the air brake system. The purge reservoir stores air that

will be used to reactivate the desiccant during the purge

cycle.

The air dryer will remain in the charge cycle until the air

brake system pressure builds to approximately 85 p.s.i. At

85 p.s.i. the EverFlow

™

electronic module is actuated and

begins the purge cycle. When the air pressure reaches

approximately 106 psi, the pressure protection valves

will open and air will be supplied to the primary reservoir,

secondary reservoir or other accessories. If the pressure

protection valves are preset to different values the valves

will open in order of lowest setting to highest setting when

charging a fl at system. The air dryer will remain in the

Note:

The AD-IS

®

air dryer purge piston has a purge control channel

drain. This allows any condensation in this area to fl ow past

a diaphragm in the top of the purge piston and out through a

channel in the middle of the central bolt of the purge assembly

to be drained. During the purge cycle this drain is closed.

Bulk Tanker

Secondary

Reservoir

Primary

Reservoir

CTI System

Pressure

Protection Valve

(Optional)

IN

CON

OUT

From

Engine

CON

RES

CON

AD-IS

®

EFM

Schrader

Valve

CON

RES

CON

GOV

3/8"

1/2"

1/2"

1/4"

CON

Bulk Offl oad CTI

Dryer OUT

Check

Valve

Supply

IN

SEC

PRI

Supply

IN

CON

Manual Valve

Accessories

Compressor

EverFlow

™

Module

Governor

Compressor

OUT

CON

EverFlow

™

IN

Discharge Line

Unloader Valve