Warning – Bendix Commercial Vehicle Systems AD-IS EVERFLOW ASSEMBLY User Manual

Page 7

7

TESTING THE AD-IS

®

EVERFLOW

™

ASSEMBLY

Before placing the vehicle in service, perform the following

tests.

1. Close all reservoir drain valves.

2. Build up system pressure to governor cut-out and note

that one AD-IS

®

air dryer purges with an audible burst of

air, followed immediately by approximately 30 seconds

of air fl owing out of the purge valve.

3. “Fan” the service brakes to reduce system air pressure

to governor cut-in. Note that the system once again

builds to full pressure and is followed by a purge at the

other AD-IS

®

air dryer exhaust.

4. It is recommended that the total air system be tested

for leakage to assure that the AD-IS

®

air dryer will not

cycle excessively.

See Bendix publication BW5057 “Air Brake Handbook" for

additional information.

BRAKING SYSTEM PROTECTION

The AD-IS

®

EverFlow

™

assembly allows the system to

maintain one brake circuit up to about 100 psi even after

a pressure loss in the other brake circuit. This allows a

vehicle to be moved (in an emergency), but with reduced

braking capacity. Compare this to a conventional system

where a loss of pressure in one service tank leaves the

vehicle with a limited number of reduced braking capacity

applications before the parking brakes automatically apply

and stay on.

ROADSIDE INSPECTION

In the event of a roadside inspection the system behavior

will be as follows: When the system is charged to

governor cut-out, and then one reservoir drain valve is

opened, initially both reservoir gauges will fall, however,

the AD-IS

®

EverFlow

™

assembly primary and secondary

pressure protection valves will close at pressures above

70 psi, protecting the remaining brake circuit from further

loss of pressure.

TEMPORARY AIR DRYER BYPASS

To temporarily bypass the EverFlow

™

assembly, the

following procedure needs to be followed.

Follow the General Safety Guidelines outlined on pages

5-6 in this document.

Make sure that all residual pressure has been released and

the air dryer purge reservoir has been drained to 0 p.s.i.,

then remove the air supply line from the compressor to the

inlet port (1 IN). Remove the safety valve from the AD-IS

®

air dryer body (see Figure 1 for location). Note that a short

puff of trapped air may vent from the safety valve port when

the valve is being removed. Install a T-fi tting into the port.

Using any adapters necessary, reinstall the safety valve

in one of the branches of the T-fi tting. Using any adapters

necessary, install the air supply line into the remaining

T-fi tting port. After testing the T-fi tting for any air leakage,

by using a soap solution after charging to system cut-out

pressure (a 1” bubble in 10 seconds is acceptable), the

vehicle may be returned to temporary service.

Note: This is a temporary bypass of the air dryer, and

full repair of the unit must be carried out at the earliest

opportunity. With the EverFlow

™

assembly removed from

the system, contaminants will be entering the air system:

reservoirs will need to be manually drained daily until

the repairs are completed. At end of each working day,

park vehicle and slowly drain pressure through the drain

valves – leave open to the atmosphere, for several hours

if possible. When repairs are carried out, be sure to check

that all reservoirs (including the air dryer purge reservoir)

are emptied of all contaminants.

If after bypassing the EverFlow

™

assembly the system

pressure still does not build, use the following procedure

to remove, clean and reinstall the delivery check valve.

DELIVERY CHECK VALVE CLEANING PROCEDURE

(Note: This is only required if system pressure does not

build after temporary bypass is completed.)

Refer to Figure 6 throughout this procedure. Depressurize

the air brake system following the General Safety

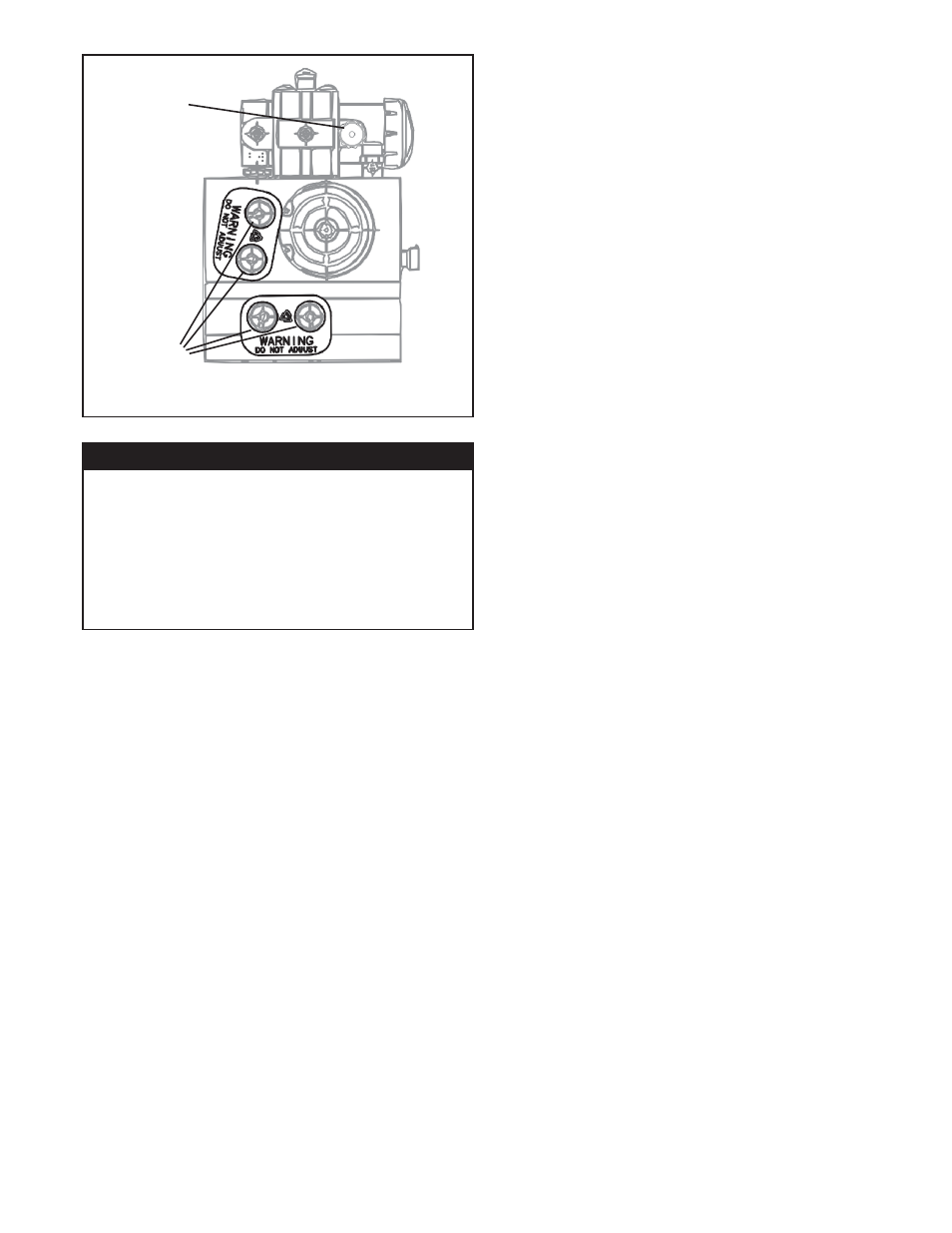

FIGURE 4- PRESSURE PROTECTION VALVE LOCATIONS

PRESSURE

PROTECTION

VALVE

LOCATIONS

AD-IS

®

AIR DRYER

GOVERNORS

ARE NON-

ADJUSTABLE

AND FEATURE A

BREATHER VALVE

IN THIS PORT

WARNING:

DO NOT ATTEMPT TO ADJUST OR

SERVICE THE PRESSURE PROTECTION

VALVES. INCORRECT PRESSURE

PROTECTION VALVE SETTINGS CAN

RESULT IN AUTOMATIC APPLICATION

OF VEHICLE SPRING BRAKES WITHOUT

PRIOR WARNING.