Ad-sp, Air dryer troubleshooting chart (continued) – Bendix Commercial Vehicle Systems AD-SP SYSTEM PURGE AIR DRYER 10/04 User Manual

Page 19

19

AD-SP

™

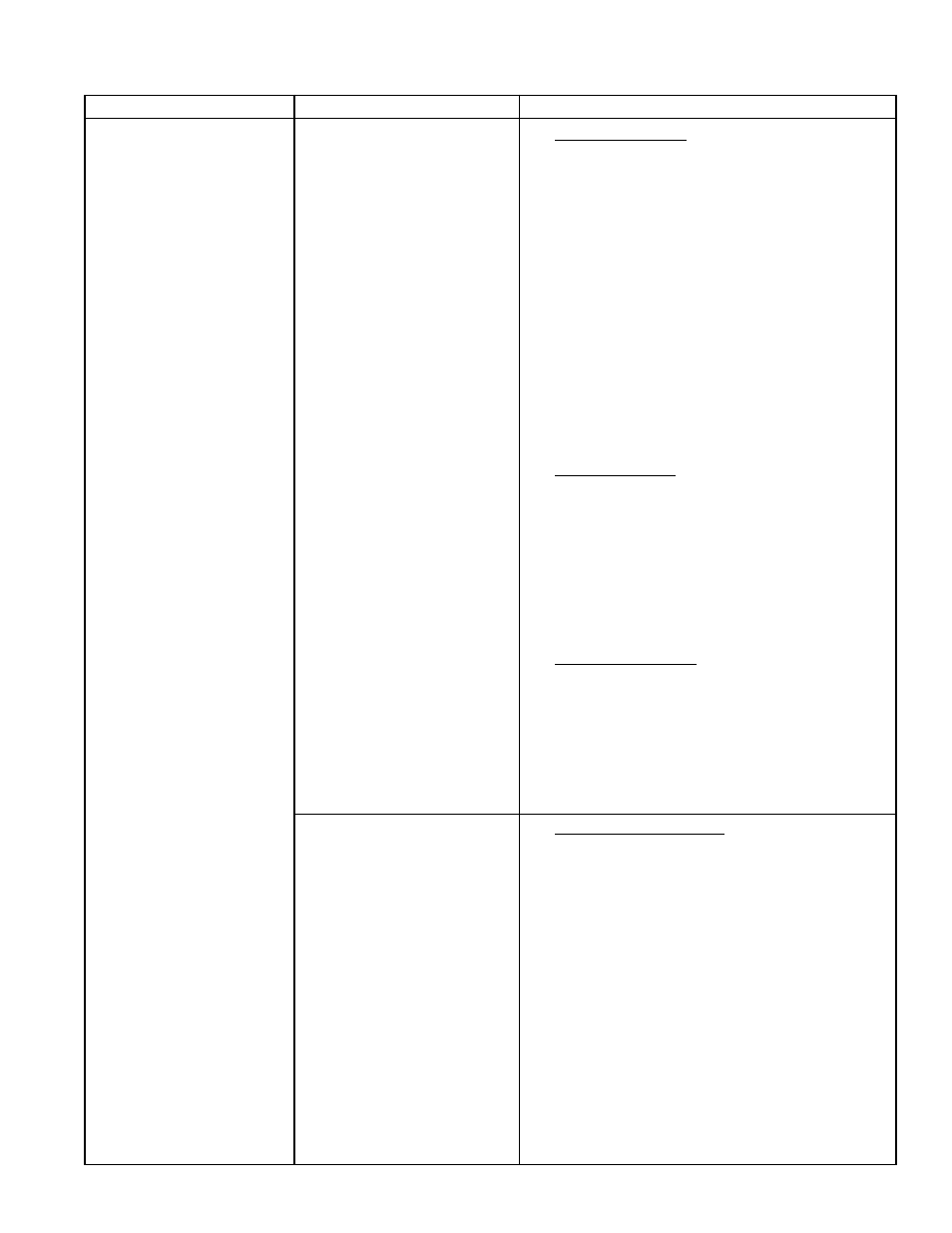

AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS

CAUSE

REMEDY

NOTE: Duty Cycle is the

ratio of time the compressor

spends building air to total

engine running time. Air

compressors are designed

to build air (run “loaded”) up

to 25% of the time. Higher

duty cycles cause

conditions that affect air

brake charging system

performance which may

require additional

maintenance. Factors that

add to the duty cycle are: air

suspension, additional air

accessories, use of an

undersized compressor,

frequent stops, excessive

leakage from fittings,

connections, lines,

chambers or valves, etc.

Charge Cycle Time - The AD-SP

™

air dryer is

designed to provide clean, dry air for the brake

system. When a vehicle’s air system is used to

operate non-brake air accessories it is

necessary to determine that; during normal,

daily operation the compressor should recover

from governor “cut-in” to governor “cut-out”

(usually 100 psi to 120 psi) in 90 seconds or

less at engine RPM’s commensurate with the

vehicle vocation. If the recovery time consistently

exceeds this limit, it may be necessary to

“bypass” the air accessory responsible for the

high air usage. An example of where a by-pass

system would be required is when the

compressor is used to pressurize a tank trailer

for purposes of off-loading product. Consult your

local authorized Bendix parts outlet or sales

representative for additional information.

Purge Cycle Time - During normal vehicle

operation, the air compressor must remain

unloaded for a minimum of 30 seconds. This

minimum purge time is required to ensure

complete regeneration of the desiccant material.

If the purge time is consistently less than the

minimum, an accessory by-pass system must

be installed. Consult your local authorized

Bendix parts outlet or sales representative for

additional information.

Air Compressor Size - Although the AD-SP

™

air

dryer can be used in conjunction with larger

compressors, it was designed primarily for units

rated for up to 30 CFM. It is recommended that

when using the AD-SP

™

air dryer with a

compressor which has a rated displacement

exceeding 30 CFM that an authorized Bendix

parts outlet or Bendix marketing representative

be contacted for assistance.

F. Restricted discharge line. See Appendix A, Table

A, column 1 & 2 for recommended sizes. If

discharge line is restricted or more than 1/16"

carbon build up is found, replace the discharge

line. Replace as necessary.

Discharge Line Freeze-Up: The discharge line must

maintain a constant slope down from the

compressor to the air dryer inlet fitting to avoid low

points where ice may form and block the flow. If,

instead, ice blockages occur at the air dryer inlet,

insulation may be added here, or if the inlet fitting is

a typical 90 degree fitting, it may be changed to a

straight or 45 degree fitting. For more information on

how to help prevent discharge line freeze-ups, see

Bendix Bulletins TCH-08-21 and TCH-08-22. Shorter

discharge line lengths or insulation may be required

in cold climates.

F. Air compressor

discharge and/or air

dryer inlet temperature

too high.