The air brake charging system – Bendix Commercial Vehicle Systems TU-FLO 750 COMPRESSOR 6/08 User Manual

Page 4

4

DUTY CYCLE

The duty cycle is the ratio of time the compressor spends

building air to the total engine running time. Air compres-

sors are designed to build air (run "loaded") up to 25% of

the time. Higher duty cycles cause conditions that affect

air brake charging system performance which may require

additional maintenance. Factors that add to the duty cycle

are: air suspension, additional air accessories, use of an

undersized compressor, frequent stops, excessive leakage

from fi ttings, connections, lines, chambers or valves, etc.

Refer to Table A in the Troubleshooting section for a guide

to various duty cycles and the consideration that must be

given to maintenance of other components.

COMPRESSOR INSTALLATION

While the original compressor installation is usually com-

pleted by the vehicle manufacturer, conditions of operation

and maintenance may require additional consideration. The

following presents base guidelines.

DISCHARGE LINE

The discharge line allows the air, water-vapor and oil-vapor

mixture to cool between the compressor and air dryer or

reservoir. The typical size of a vehicle's discharge line,

(see column 2 of Table A in the Troubleshooting section)

assumes a compressor with a normal (less than 25%) duty

cycle, operating in a temperate climate. See Bendix and/or

other air dryer manufacturer guidelines as needed.

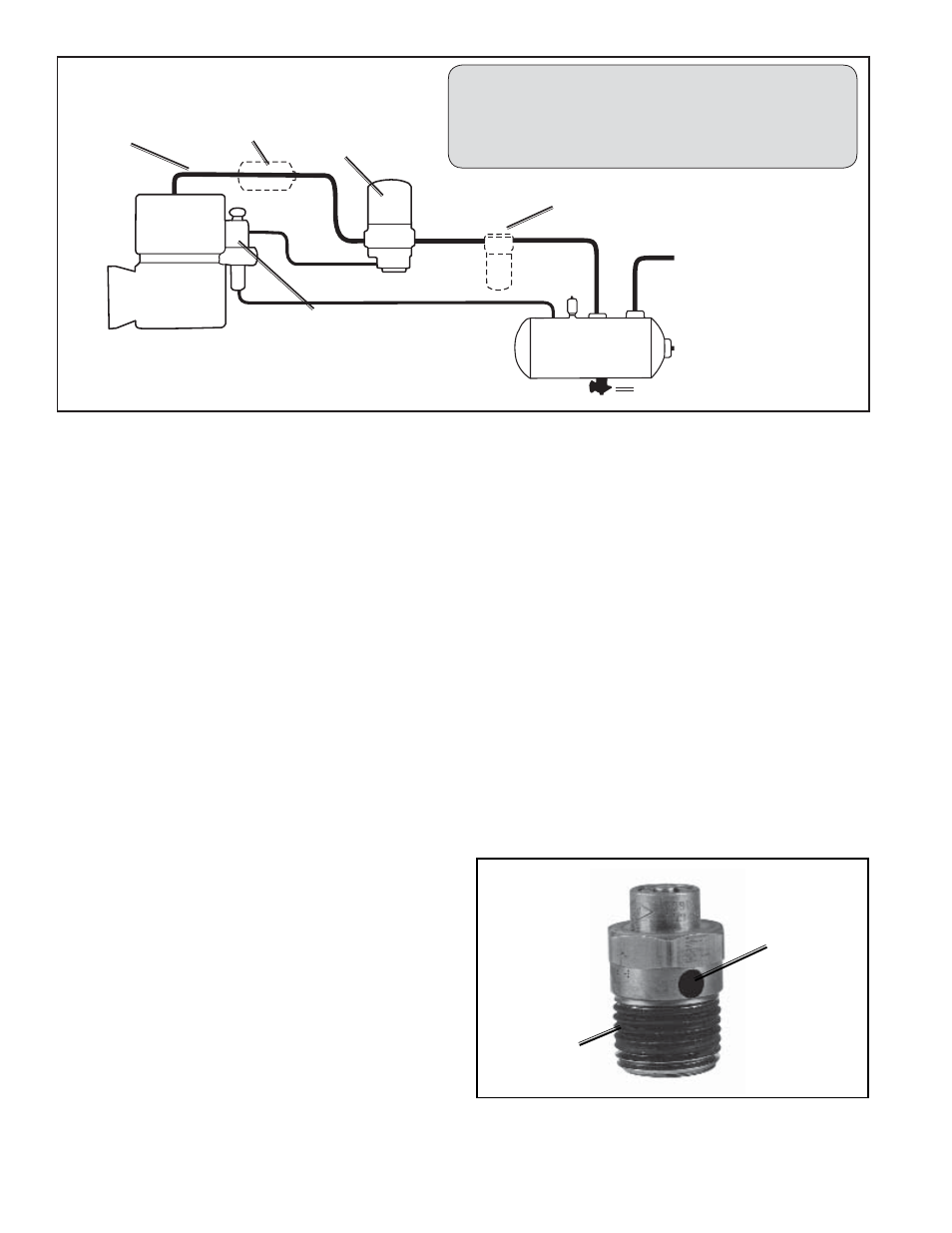

FIGURE 6A - SYSTEM DRAWING

Air Dryer

Reservoir Drain

Service Reservoir

(Supply Reservoir)

Compressor

Governor

(Governor plus Synchro valve

for the Bendix

®

DuraFlo

™

596

Compressor)

Discharge

Line

Optional “Ping” Tank

Optional Bendix

®

PuraGuard

®

QC

™

Oil Coalescing Filter

The Air Brake Charging System

supplies the

compressed air for the braking system as well as other air

accessories for the vehicle. The system usually consists

of an air compressor, governor, discharge line, air dryer,

and service reservoir.

The discharge line must maintain a constant slope down

from the compressor to the air dryer inlet fi tting or reservoir

to avoid low points where ice may form and block the fl ow.

If, instead, ice blockages occur at the air dryer or reservoir

inlet, insulation may be added here, or if the inlet fi tting is

a typical 90 degree fi tting, it may be changed to a straight

or 45 degree fi tting. Shorter discharge line lengths or

insulation may be required in cold climates.

While not all compressors and charging systems are

equipped with a discharge line safety valve this compo-

nent is recommended. The discharge line safety valve is

installed in the cylinder head (Tu-Flo

®

550/750) or close to

the compressor discharge port and protects against over

pressurizing the compressor in the event of a discharge

line freezeup.

FIGURE 6B - DISCHARGE LINE SAFETY VALVE

HOLE

THREAD