Troubleshooting- faults – B&D Mfg Smart User Manual

Page 16

16

ALL THE PUMP YOU NEED AND MORE

Revised 7-5-12

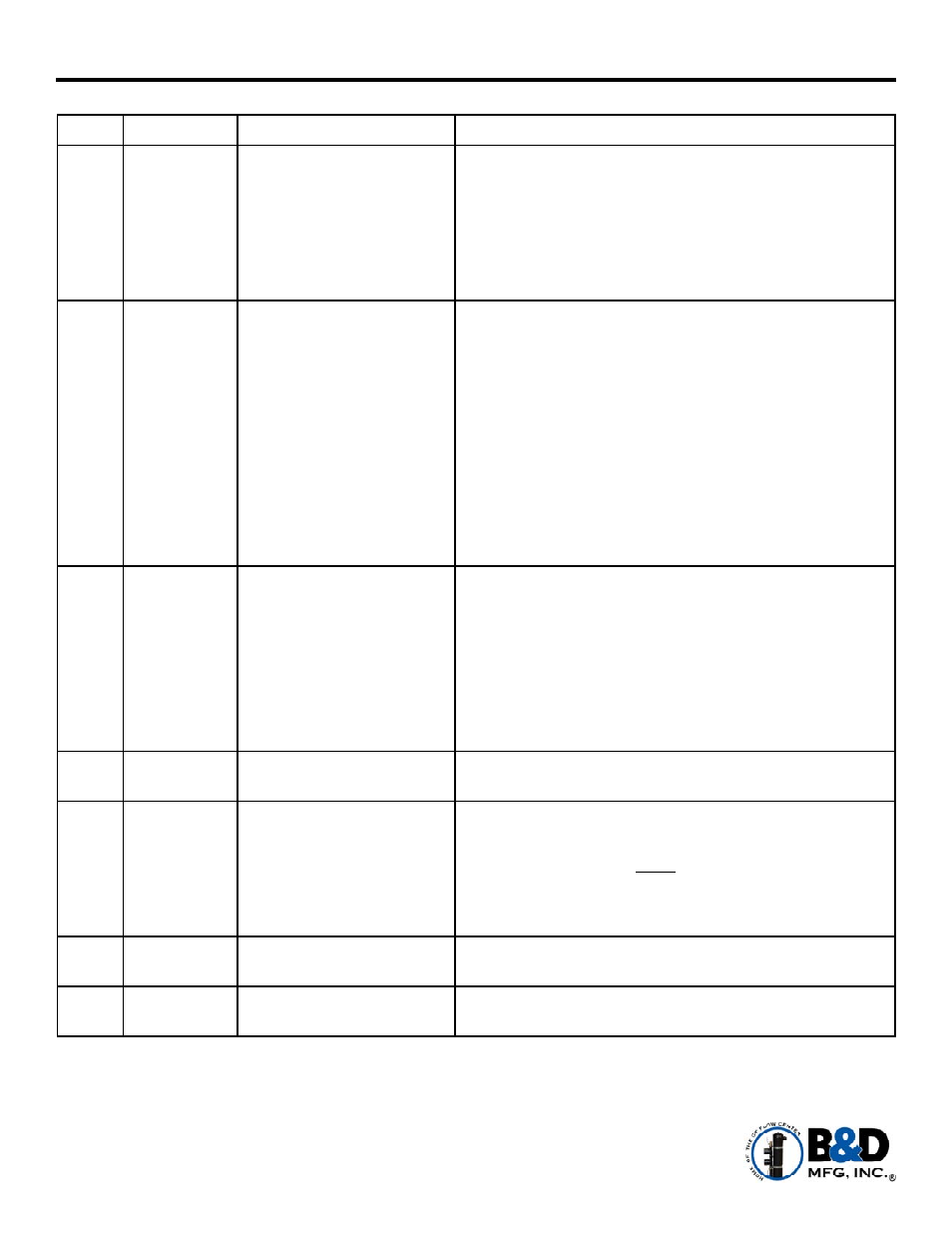

Troubleshooting- Faults

Faults Description

Suggestion(s)

oL1/

oL2

Motor/Drive

Overload

Leave power to drive off for three minutes. Check to make

sure the motor coupling spins freely by hand.

System may not be balanced for flow.

Exceeding the flow rate of the pump design.

Supply voltage too low.

oC Over

Current

Meg the motor to determine the insulation resistance is

within specification (refer to back of manual).

Inspect the motor leads and terminal wires for exposed

shorts or grounds.

Leave power to drive off for three minutes. Check to make

sure the motor coupling spins freely by hand.

Maximum PSI Ratings:

CR32-1-1 = 30 PSI

CR32-1 = 35 PSI

CR45-1-1 = 39 PSI

FbL

Feedback

Loss

Make sure the wiring for the transducer is correct. Check

for loose wires on the connection of the transducer “+V”

and “A2”.

+V = Brown

A2 = Black

Check water level in canister.—Must have a minimum of

three feet of water above inlet.

OH

Heatsink Over

Temperature

Make sure the fan is in operation when the drive is

operating.

Uu Under

Voltage

Make sure voltage supply (1x230) to the V1000 is

between 200 and 240 volts.

Reason(s)

Motor/Drive current has

exceeded service factor

amps.

Motor insulation damage.

One of the motor cables

has shorted.

Load too heavy.

Pressure set too high.

Transducer out of range.

Temperature limit of the

drive is exceeded.

Main out of range.

oU

Over Voltage Main out of range.

Make sure voltage supply (1x230) to the V1000 is

between 200 and 240 volts.

LF

Phase Loss on

Output Side

of Drive

Wiring issue.

Make sure all leads to motor are connected to the drive

and are solid connections. Motor may be incorrectly wired

for 3x460V, the motor MUST be wired for 3x230V.

Wire connections in motor terminal box may be loose,

double check connections.