Opération, Pour un fonctionnement sécur, Procédure de rodage – Briggs & Stratton 203721GS User Manual

Page 10: Operation, Notice, Warning

10

BRIGGSandSTRATTON.COM

Operation

If you have any problems with operation of your air

compressor, call air compressor helpline at (800) 743-4115.

If calling for assistance, please have the model, revision, and

serial number from the data tag available.

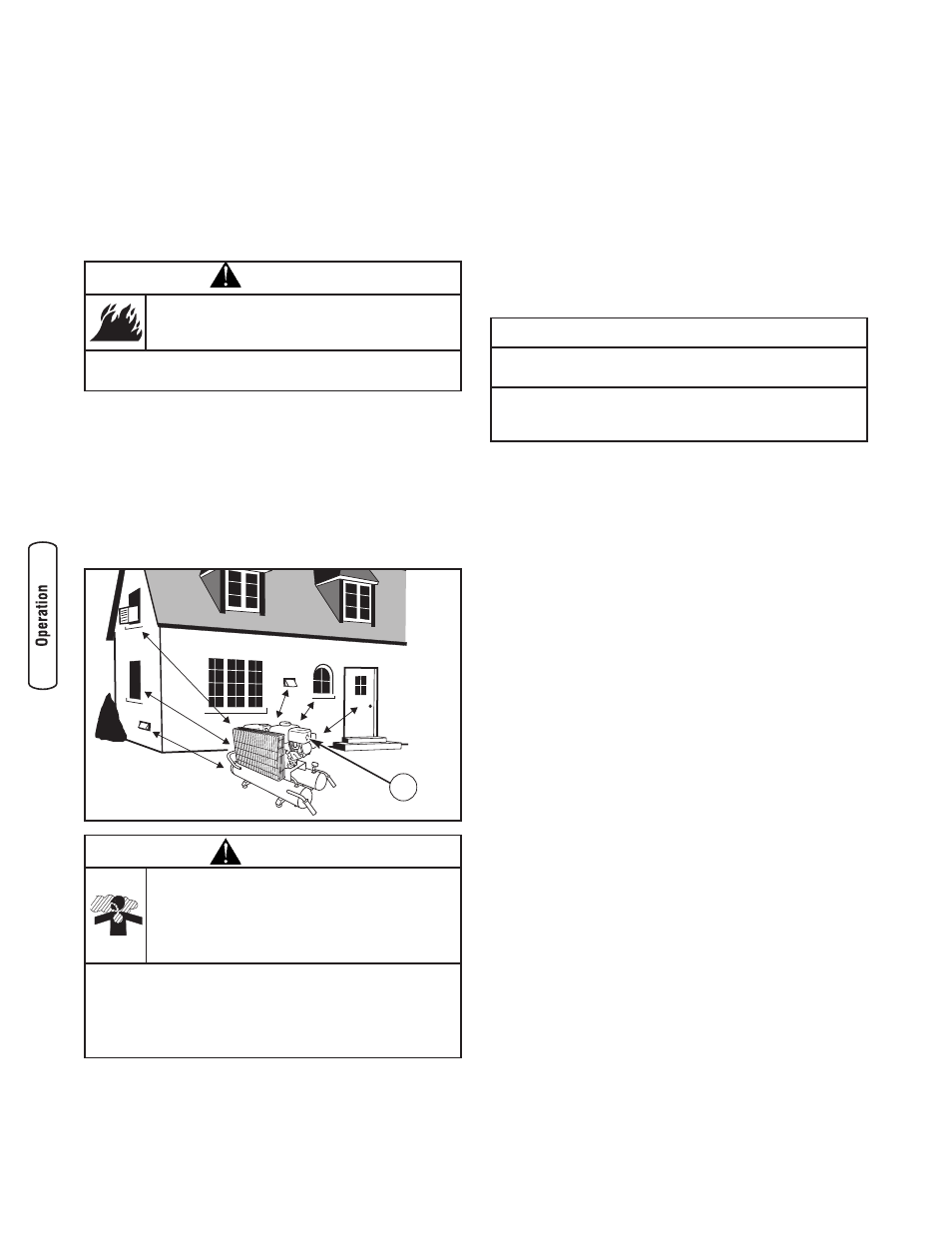

Air Compressor Operating Location

Clearances and Air Movement

Place air compressor outdoors in an area that will not

accumulate deadly exhaust gas. DO NOT place air

compressor where exhaust gas (A) could accumulate and

enter inside or be drawn into a potentially occupied building.

Ensure exhaust gas is kept away from any windows, doors,

ventilation intakes, or other openings that can allow exhaust

gas to collect in a confined area. Prevailing winds and air

currents should be taken into consideration when positioning

air compressor.

The air compressor pump is designed to allow for proper

cooling. The ventilation openings on the compressor are

necessary to maintain proper operating temperature. DO

NOT place rags or containers on or near these openings.

Keep the air filter clear of obstructions that could reduce

airflow to the air compressor.

Operate the air compressor with unit located on a flat surface

to ensure that it receives proper lubrication.

Break-In Procedure

Before first use of this equipment, the system must undergo

a break-in operation, as described in this section.

1. Open both drain valves (rotate fully counterclockwise)

to prevent air pressure build-up in air tank during

break-in period.

NOTE: Always drain air tank over a washable surface or in a

suitable container to prevent damaging or staining surfaces.

2. Start your air compressor following steps 1 through 7

in the section Starting Your Air Compressor.

3. Run compressor for 15 minutes. Make sure start valve

and drain valves remain open.

4. After 15 minutes, with air compressor running, close

start valve (flip pin down to a horizontal position) and

both drain valves (rotate fully clockwise). Air tanks will

fill to “cut-out” pressure and engine speed will slow to

idle.

NOTE: If you hear leaking air, pull quick connect coupler

back until it clicks to reset coupler valve.

5. Turn your air compressor off as described in Stopping

Your Air Compressor.

NOTE: Check oil level in compressor after break-in.

The compressor has completed the break-in procedure and

is ready for normal use.

NOTICE

Serious damage may result if the break-in instructions are

not closely followed.

• This procedure is required before the air compressor is put into

service and when the check valve or a complete compressor

pump has been replaced.

WARNING

Exhaust heat / gases can ignite combustibles,

structures or damage fuel tank causing a fire.

• Keep at least 5 ft. (1.5 m) clearance on all sides of air

compressor including overhead.

A

WARNING

Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting or death.

• Operate air compressor ONLY outdoors.

• Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes, or other openings.

• DO NOT start or run engine indoors or in an enclosed area, even

if windows and doors are open.