Schwank ecoSchwank Millivolt User Manual

Page 6

ecoSchwank-MILLIVOLT / IL-MILLIVOLT Manual

IM090128

RD: JAN 2009

RL: 1D

BA

The maximum supply pressure must be limited to 14" W.C. (0.51 psi). If the line pressure is above 14"

W.C., then a separate pressure reducing regulator must be used. The minimum pressure at the inlet to

the heater regulator must be equal to or greater than 6.0" W.C. for natural gas and 11.0" W.C. for pro-

pane gas.

A sealed regulator is supplied with the heater which maintains the proper manifold pressure when the

main burner is operating under the following pressure:

2.7 GAS SUPPLY LINE INSTALLATION

A. All piping must be installed according to local

codes.

B. It is recommended to install an approved

flexible connector between the heater and gas

piping available as option from Schwank.

C. A drip-pocket at the inlet connection must be

provided.

D. On propane-fired units, a main line filter is

recommended.

E. Piping joint compounds must be resistant to

the action of liquefied petroleum gases.

F. All piping joints should be tested for leaks

with a soap and water solution.

Do not install any gas piping in heat zones. Do not subject heater controls

to leak test pressures when checking the main supply piping.

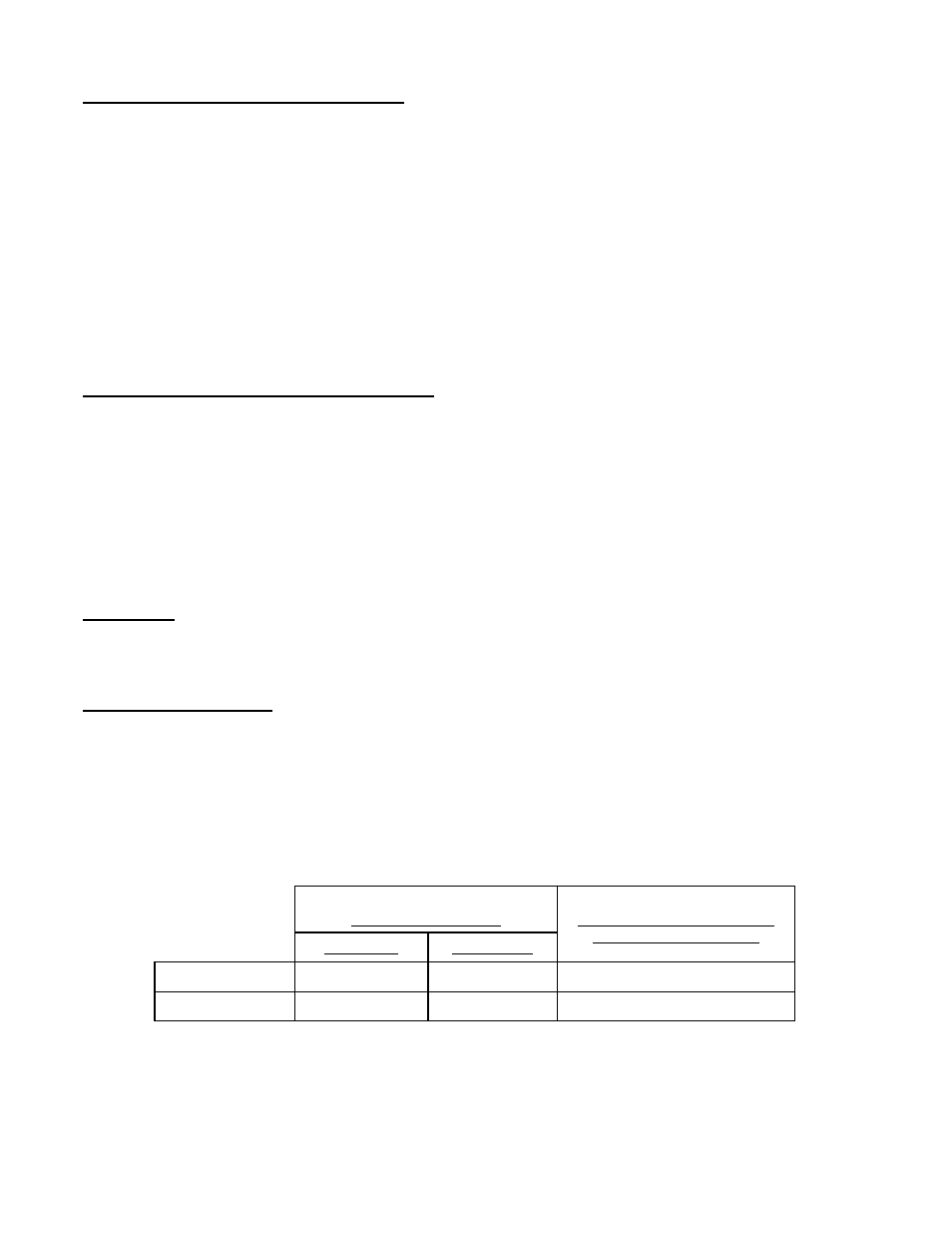

2.8 GAS PRESSURE

LINE PRESSURE IWC

MANIFOLD PRESSURE IWC

AT TAP IN GAS VALVE

MINIMUM

MAXIMUM

NATURAL GAS

6.0

14.0

5.0

PROPANE GAS

12.0

14.0

10.0

The heater orifice is sized for the following fuel gas heat content:

Natural gas: 1,000 BTU/CU FT.

Propane gas: 2,500 BTU/CU FT.

2.6 VENTILATION REQUIREMENTS

Canada: it is required by law that an unvented heater be electrically interlocked to an independent ex-

haust fan by means of an Air Proving Switch. The exhaust fan must be sized to create 3 cfm for every

1000 Btu/hr or fraction thereof, of total input of installed equipment. Consult CSA.B149.1 latest edi-

tion for requirements.

USA: when a heater is installed unvented the system requires the exhausting of at least 4 cfm per 1000

Btu/hr on NG, and 4.5 cfm per 1000 Btu/hr for LP. By natural or mechanical means, or to an independ-

ent exhaust fan, for the total input of all heaters installed. Exhaust openings for removing flue products

shall be above the level of the heaters.. Consult your local codes and ANSI Z223.1 latest edition.

CAUTION:

Page 3