Schwank ecoSchwank Millivolt User Manual

Page 10

ecoSchwank-MILLIVOLT / IL-MILLIVOLT Manual

IM090128

RD: JAN 2009

RL: 1D

BA

8. TROUBLE SHOOTING GUIDE

SYMPTOMS

POSSIBLE CAUSES OR CORRECTION

1. Pilot will not light

a. Make certain the gas supply is turned on.

b. Air in line. Continue to relight until air is purged.

c. Check for a blocked pilot orifice.

2. Pilot outage

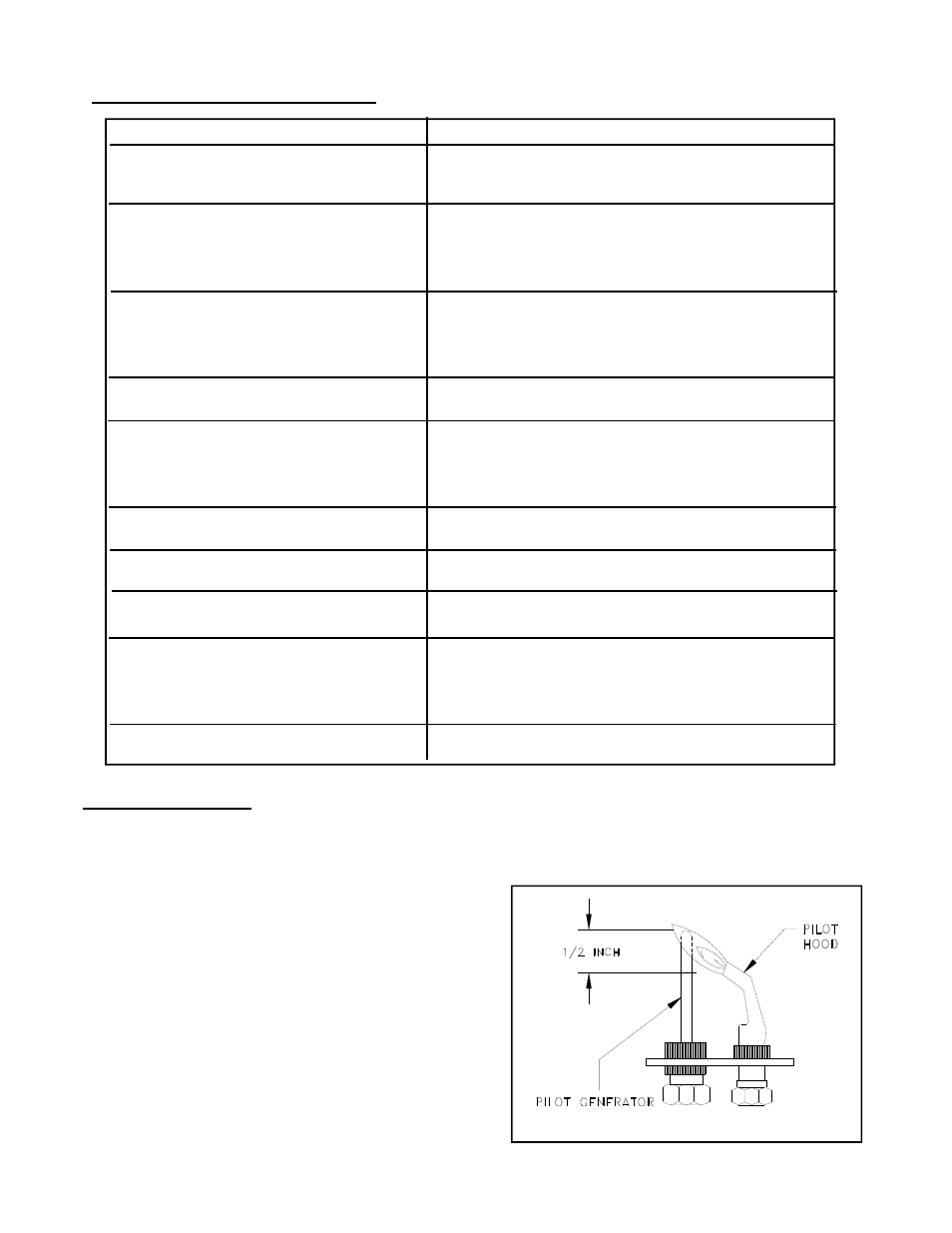

a. Improper pilot flame adjustment. Refer to Figure 7.

b. Check pilot generator contacts and tighten if necessary.

c. Defective pilot generator—replace.

d. Defective valve—replace

3. Pilot flame will not stay lit when valve

a. Improper pilot flame adjustment. Refer to figure 7.

knob is released

b. Remove pilot orifice—check and clean—reinstall.

c. Defective thermostat—replace.

d. Defective valve—replace.

4. Burner goes out.

a. Thermostat satisfied—normal operation.

b. Defective valve—replace.

5. Main burner and pilot goes out.

a. Improper venting or blocked flue. Correct venting

problem and relight.

b. Strong Wind conditions.—restart heater.

c. Make sure the gas supply is turned on.

6. Burner back-flashes or makes noise.

a. Check burner and orifice for damage. Replace if necessary.

b. Check for cracked tile. Replace if necessary.

7. Yellow main burner flame.

a. Check and clean burner and orifice.

b. Check line and manifold gas pressure.

8. Yellow pilot flame.

a. Small yellow tip—normal operation.

b. Remove pilot orifice – check and clean—replace.

9. Poor thermostatic control.

a. Check for proper setting.

b. Check wall thermostat section or gas valve assembly.

c. Replace thermostat section or gas valve assembly.

d. Check wall thermostat location.

10. Main burner will not light

a. Check thermostat setting.

b. Check to see if valve is in the ON position.

8.1 MAINTENANCE

The efficiency of the heater can be impaired if it gets dirty. If the heaters are installed in areas where consider-

able dust is present in the air, periodic burner cleaning may be necessary. Dust may be entrained in the primary

air supply and deposited on the back side of the ceramic tiles. This can be very easily removed by cleaning the

ceramic face and the air inlet with a blast of low pressure

air, a maximum of 20 psi. Do not direct the air stream at

the gasket material between the tiles and burner body.

Occasionally pilots or the main burner refuse to function

properly after a summer shutdown. For the pilot, this prob-

lem can be corrected by removing the pilot burner and

cleaning out the gas passageways. The main burner pas-

sageways can be cleaned out by using a flexible brush

comparable to the type used to clean glass bottles. (In

several instances, small cocoons or spider webs have

been found present in these areas.) Preventative mainte-

nance is the best policy

.

Heaters should be cleaned once

a heating season.

FIG. 7

Page 7

(Thermocouple)