Schwank 2-Stage Series User Manual

Page 16

16

SET(U)-F / ITT(U)-F Manual

IM091221

RD: FEB 2014

RL: 8B

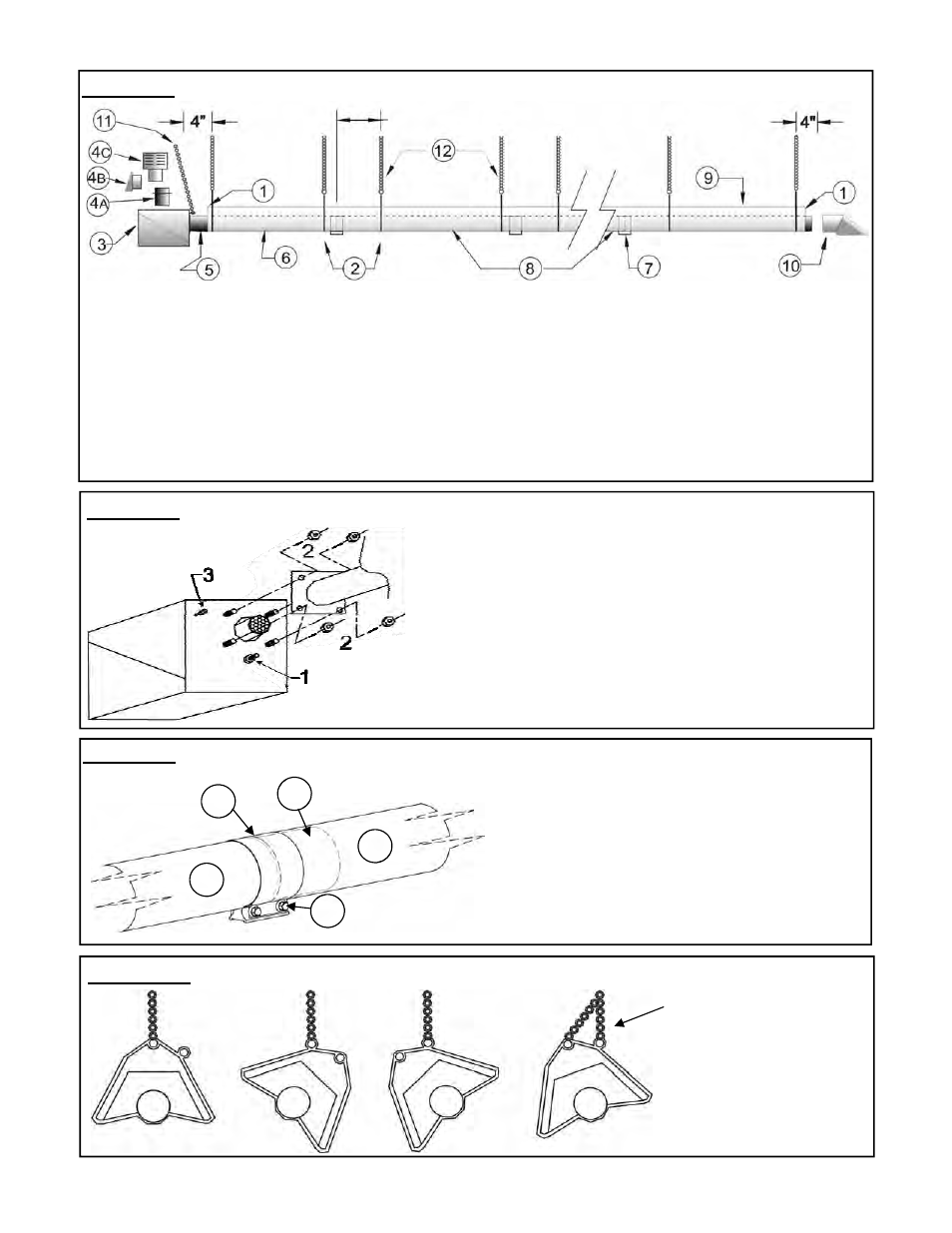

FIGURE 9: COUPLER INSTALLATION (NOTE: See Section 9.3 for ‘Special Couplers’ at

first tube joint: 100,000 x 20 ft & 175 / 200,000 models)

1. Tube

2. Swaged end of upstream tube

3. Tube

Coupler

4. Centre coupler over tube joint

Tighten coupler bolts to 40 ft-lbs.

Note: Flange Gasket not required between burner and

tube flange

1. Fifth Nut (Holds Inner Burner to Housing - Do Not

Loosen or Remove)

2. Insert four burner bolts through the tube flange,

secure tightly with lock nuts.

3. Secure suspension chain to eye bolt to stabilize

burner

FIGURE 8: BOLT BURNER TO TUBE FLANGE

FIGURE 10: HANGER / REFLECTOR ORIENTATION HORIZONTAL TO 45

0

FOR ANGLE LESS

THAN 45° USE

CHAIN TO BOTH

EYES ON HANGER

45°

45°

4

3

1

1

2

FIGURE 7: STRAIGHT TUBE TYPICAL HANGER & SUPPORT SPACINGS

8 - STEEL TUBE(S)

9 - REFLECTOR

10 - FLUE VENT TERMINAL

11 - BURNER SUPPORT CHAIN

12 - HANGER SUPPORT

CHAINS

4B - JS-0532-VC 4” WALL CAP

4C - JA-0528-XX 4” ROOF CAP

5 - SIGHT GLASS

6 - ALUMINIZED TUBE WITH

FLANGE

7 - TORCTITE TUBE COUPLER

1 - END CAP

2 - WIRE HANGER

3 - BURNER ASSEMBLY

4 - COMBUSTION AIR OPTIONS:

4A - JS-0532-SE 4” INTAKE

ADAPTER

SUSPEND ALL TUBES BY TWO (2) HANGERS PER 10’ LENGTH, LOCATE HANGERS BETWEEN 6”

to 24” FROM EACH TUBE CONNECTION.

1ST & 2ND TUBES FROM BURNER END: INSTALL WELDED SEAM FACING DOWNWARD.

6” MIN. to 24” MAX.