S&S Cycle Three Piece Flywheel Assemblies for 1999-Up Harley-Davidson big twin engines and S&S T-Series engines User Manual

Page 4

14. Endplay should be between .001" and .005". If endplay is less than

.001" a thicker spacer must be used. If endplay is greater than .005"

a thinner spacer must be used. When the bearing end play is within

specification, the flywheels can be installed in the crankcases.

15. Support the flywheel assembly in a stand with the sprocket shaft

straight up. A coffee can or small bucket works well for this.

16. Use a sprocket shaft bearing installation tool (such as S&S PN 53-

0060) to press the inner bearing onto the sprocket shaft against the

flywheel.

17. Place the left crankcase half over the sprocket shaft.

18. Install the Timken bearing spacer and position the outer Timken

bearing on the shaft.

19. Use the sprocket shaft bearing installation tool to press the bearing,

shaft and case together.

20. Turn the left crankcase and flywheel assembly over so the pinion

shaft is straight up. Support the crankcase half so it is stable.

21. S&S® uses and recommends Threebond® 1184 to seal the joint

between left and right crankcases. Apply a consistent thin coat to

both cases, taking care not to get any material in a place where it

could get inside the engine. Take special care not to block oil return

passages.

22. Allow sealant to cure per the manufacturer’s instructions and install

the right crankcase half.

23. In order to assemble the right side case half S&S recommends the

use of a pinion shaft guide (Jims® #1288 or similar). The guide fits

over the pinion shaft as shown in Picture 4, above. The shaft

guide positions the rollers in the right crankcase bearing so the

shaft can slip through as the right case is lowered into place.

24. Install the case bolts and tighten the 5/16" fasteners to 18 ft-lbs.

The center case bolt in S&S crankcases in a ¼" bolt and should be

tightened to 120 in-lbs. Use the sequence in Fig. 1, above.

25. When the crankcase has been assembled, confirm that the flywheel

endplay specification is within .001"–.005".

26. Load the bearing with either a sprocket shaft nut and spacer or a

bearing installer tool.

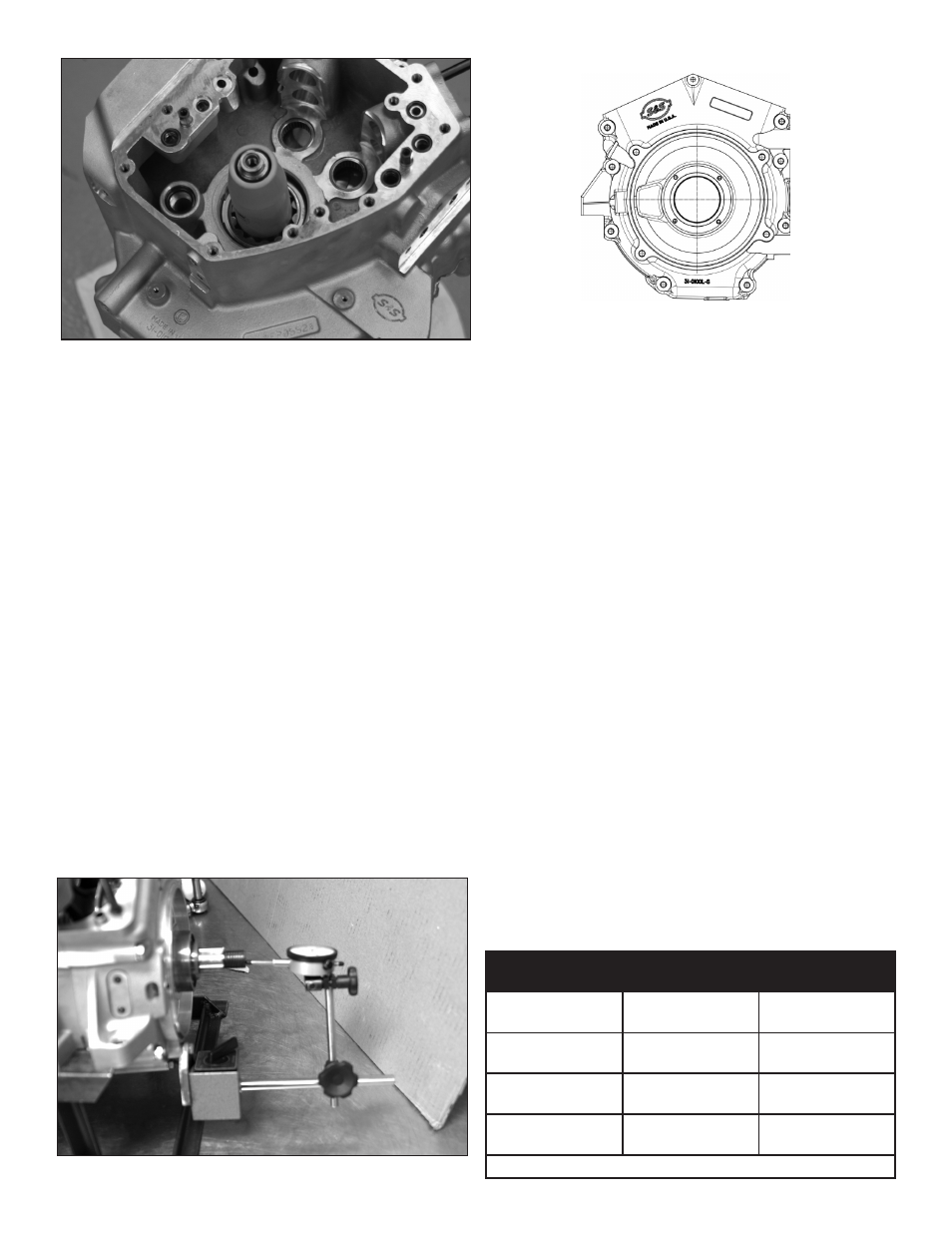

27. Mount a dial indicator on the right side of the lower end assembly.

Put the indicator on the pinion shaft so it measures in and out

horizontal shaft movement. See Picture 5, below left.

28. Rotate the shaft and push in on it, noting the indicator reading.

Rotate the shaft and pull on it, noting the dial indicator reading.

The difference between the two readings is the endplay—it should

be between .001" and .005".

29. If endplay is not within this range, the main bearing spacer must

be changed. Remember a thinner spacer will produce less endplay.

30. With the flywheel assembly installed in the crankcases, the rest of

the engine may be assembled. Follow steps outlined in stock or

S&S service manual. In addition, follow any special steps required

for any aftermarket or high performance components used in the

engine.

CLEARANCE SPECIFICATIONS

S&S® THREE PIECE FLYWHEEL ASSEMBLY

COMPONENT

FACTORY

SPECIFICATION

SERVICE

WEAR LIMIT

CONNECTING ROD

SIDEPLAY

.005"–.035"

.040"

WRISTPIN

CLEARANCE

.0007"–.0013"

.002"

PINION SHAFT

RUNOUT*

.003" MAX

-

*w/o compensator or charging system installed

4

1

3

5

7

6

8

2

4

9

Fig. 1

Picture 5

Picture 4