S&S Cycle Three Piece Flywheel Assemblies for 1999-Up Harley-Davidson big twin engines and S&S T-Series engines User Manual

Page 2

SPECIAL TOOL REQUIREMENTS

• Harley-Davidson® service manual or S&S® service manual for

the specific model or engine you are working on

• Timken® bearing install tool - for engines with Timken sprocket shaft

bearings

• Feeler gauge

• Dial indicator

• Torque wrench

GENERAL INFORMATION

• Thoroughly read and understand the section that pertains to the

flywheels you are installing.

• If you don’t have the required tools or knowledge for installing these

flywheels you should have a qualified shop install them.

• It is the engine builder’s responsibility to confirm proper clearances

when assembling an engine.

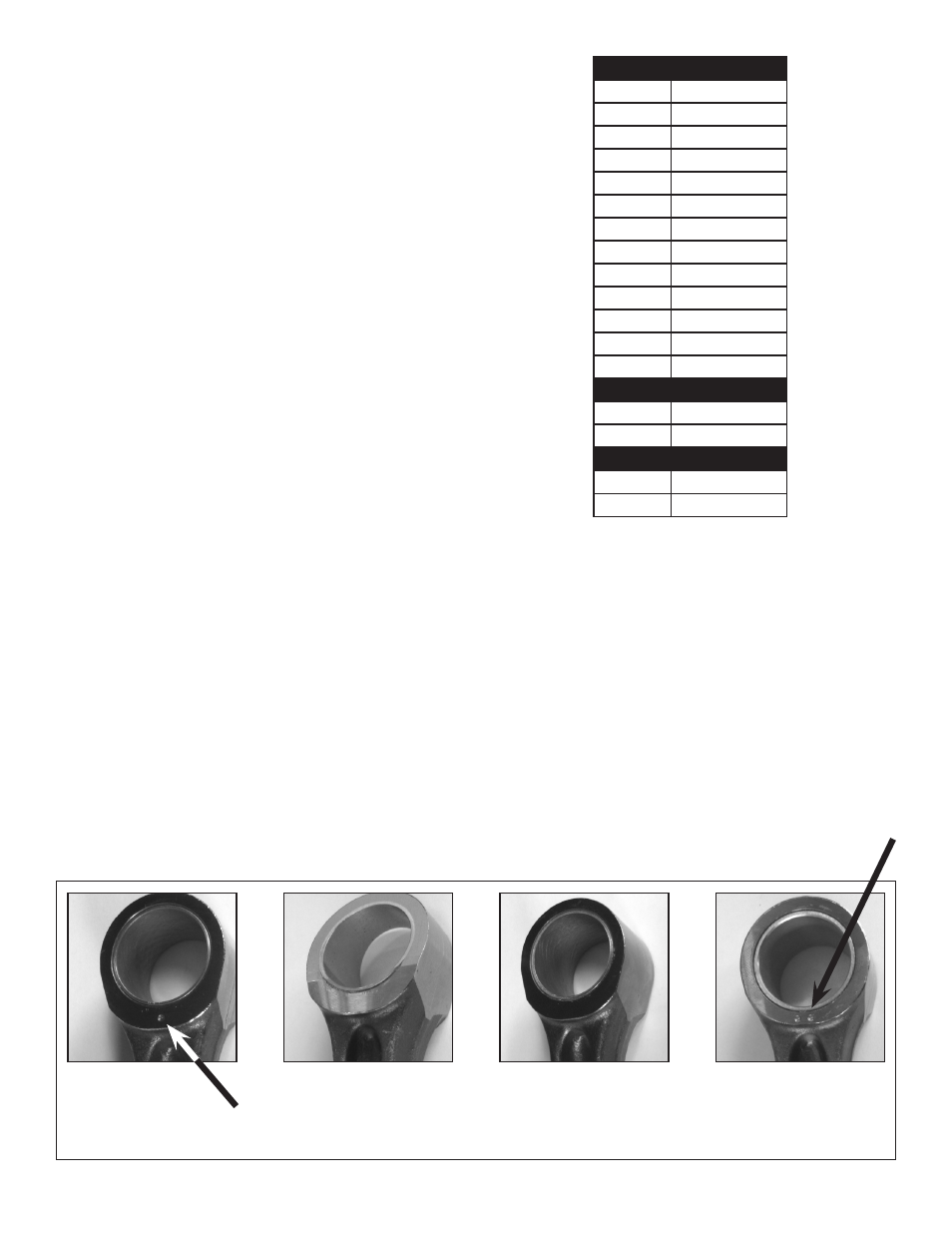

• S&S produces flywheel assemblies with connecting rods of three

different lengths. Make sure the connecting rods are correct for your

application: (See Picture 1, below)

• 1999–’06 — 7.667" length - marked with one dot

• 2007–up — 7.659" length - not marked (no dot) Tapered wristpin

end for stock pistons - straight wristpin end for performance pistons

• 120R Engines — 7.575" length - marked with two dots

• If using stock pistons for 2007 and later engines, connecting rods

must have tapered wristpin bosses to fit the internal profile of the

pistons. These rods are not rebuildable.

DISASSEMBLY

1. Refer to the Harley-Davidson service manual or S&S service manual

for the specific model or engine you are working on for the correct

disassembly procedure.

2. The engine will need to be removed from the frame of the motorcycle

and completely disassembled.

INSTALLATION

Preparation for Installation

1. Remove flywheel assembly from packaging material. Handle with

care to avoid dropping and potentially cutting your hands on sharp

edges.

2. Using a lint free cloth and lacquer thinner, thoroughly clean flywheel

assembly to remove rust preventative oil.

3. Do not immerse or wash the flywheel in a solvent tank. Connecting

rod bearings are coated in grease which may become contaminated

by dirt and debris if put in a solvent tank.

STROKE CODES

CODE

STROKE

-

3.600"

21

37/8"

17

4"

19

41/8"

9

43/16"

5

4¼"

1

43/8"

2

4½"

6

45/8"

3

4¾"

7

413/16"

4

5"

ENGINE STYLE

CODE

ENGINE STYLE

SF3

1999–UP BT

FLYWHEEL DIAMETER

CODE

DIAMETER

X

8¼"

4. If flywheel is checked for runout, measurements should be checked

at the bearing surfaces while fixtured on the mainshaft centers in a

truing stand. The total indicated runout (TIR) for new S&S flywheels

should be less than .0005".

5. Inspect flywheel assembly to make sure you have the correct style,

diameter, stroke, and mainshafts are correct for your application.

See identification chart above.

Flywheel Installation

1. Replace the pinion shaft bearing in the right side crankcase with a

new bearing. Follow factory procedures.

2. Check flywheel and connecting rod to crankcase clearances. This is

of particular importance with longer than stock strokes.

a. Install flywheel assembly in right crankcase only.

b. Assemble pistons without rings on their proper connecting rods.

Installation of wristpin clips is not necessary.

2

Picture 1

1999–’06

One Dot

2007–up

with stock pistons -

tapered crankpin boss -

No Dots

120R Engines

Two Dots

2007-up

with performance pistons -

straight wristpin end -

No Dots