S&S Cycle Lloydz Motorworkz 107 and 114 Big Bore Kit for Victory Motorcycles User Manual

Page 7

7

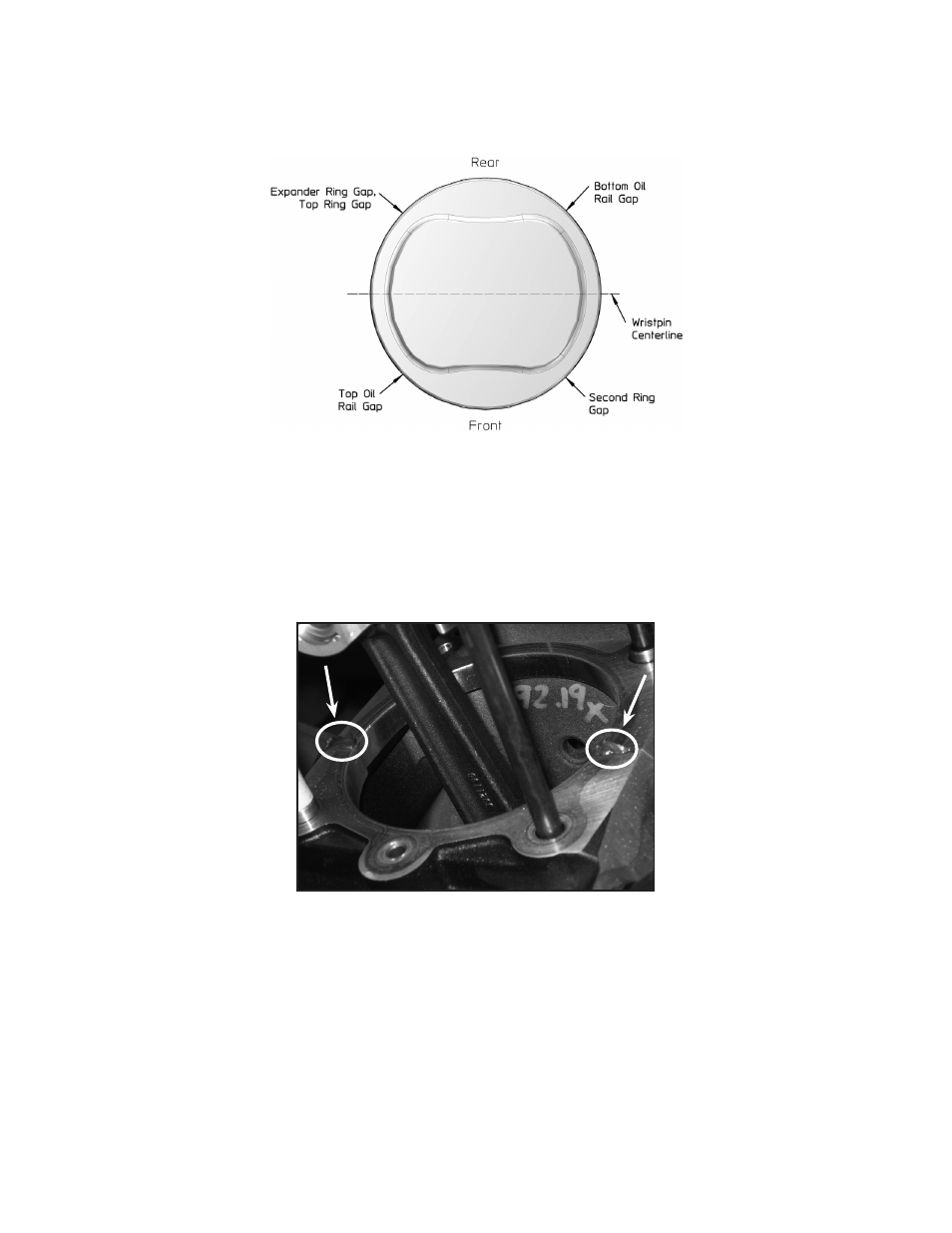

PISTON RING ORIENTATION

1- Piston ring gaps will need to be oriented to proper position before the cylinder is installed. Follow the diagram below for proper orientation of

piston ring gaps.

2 – Once the front and rear piston ring gaps are properly oriented you can move on to cylinder installation.

FRONT CYLINDER INSTALLATION

1- Remove plastic sheeting from crankcase and wipe the engine case base gasket surface clean of any oil or debris on both front and rear gasket

surfaces.

2- Apply Loctite® 598 sealer or an equivalent sealer to the crankcase parting line where the front base gasket will be placed as illustrated in Picture 8.

3- Remove the rubber tubing from the front cylinder studs and install a new Polaris® base gasket, Polaris part number 5244365.

4- With the front piston at Top Dead Center (TDC) apply a light coating of oil to the piston, rings and cylinder walls.

5- Verify that the ring gaps are orientated correctly and install a piston ring compressor around the piston and rings and compress the rings so

the cylinder can be installed.

6- Install cylinder over piston and piston rings and remove ring compressor.

7- Finish sliding the cylinder down until it seats against the base gasket.

8- If there is excess oil from cylinder installation on the head gasket surface of the cylinder wipe it off at this time.

9- Install one of the supplied head gaskets on top of the cylinder. Both head gaskets are the same and can only be installed in one direction. Head

gaskets are designed to be installed dry. Make sure there is no oil on the machined cylinder gasket surface or the head gasket.

10- Install the cylinder head followed by the cam carrier.

NOTE: If the cam is installed into the cam carrier assembly, make sure the lobes of the cam are facing down so the rocker arms are not opening the valves

when torqued down.

Picture 8