S&S Cycle Lloydz Motorworkz 107 and 114 Big Bore Kit for Victory Motorcycles User Manual

Page 2

2

ENGINE SPECIFICATIONS AND GENERAL INFORMATION

•

The rear pistons are notched to accommodate a 108mm stroke crank with 175.5mm connecting rod.

•

The big bore kit is intended for all 2003 and up Victory® motorcycles.

•

Lloydz Motorworkz recommends using the stock 100” / 106” green clutch spring and the Variable Pressure Plate Clutch when installing the

107”/114” big bore kit.

•

It is up to the technician to ensure that the motorcycle is running the proper air/fuel mixture.

•

In all cases it is the engine builder’s responsibility to confirm proper engine clearances and thoroughly read and understand the assembly

instructions prior to assembly to ensure the proper tools and parts are present to complete the engine build.

•

Pistons are fit to the cylinders in which they are received and must be kept together.

•

The 107” and 114” big bore kits are intended to use stock Victory base gaskets, part number 5244365.

•

The 107” and 114” big bore kits are designed to use the supplied head gaskets in the kit.

•

Failure to follow instructions and perform required clearancing, installation and/or break-in procedures may result in damage to pistons and or

other engine components not covered under warranty.

CLEANING AND PREPARATION OF PISTONS AND CYLINDERS

Always wear eye protection when using parts cleaner and compressed air.

1- Thoroughly clean the front and rear cylinders for assembly. Lloydz Motorworkz recommends cleaning the cylinders in mineral spirits to clean

the oil from the cylinder walls and then clean with hot soapy water and a soft plastic brush or cloth wash rag. Rinse soap off with hot water and

blow dry with compressed air. Immediately coat the cylinder lines with a film of engine oil.

2- Wash pistons in mineral spirits to clean oil from the pistons and then with hot soapy water and wash rag. Rinse pistons with hot water and blow

dry with compressed air. Immediately coat the cylinder liners with a film of engine oil.

CHECKING AND SETTING RING END GAPS

NOTES:

•

Important! The gap of the second ring should be larger than the top ring; this will help keep the top ring seated for improved performance.

•

Each piston ring must be fit to the particular cylinder in which they will be installed.

•

Oil rails can be installed without adjusting the end gap. The minimum gap should be 0.010”

•

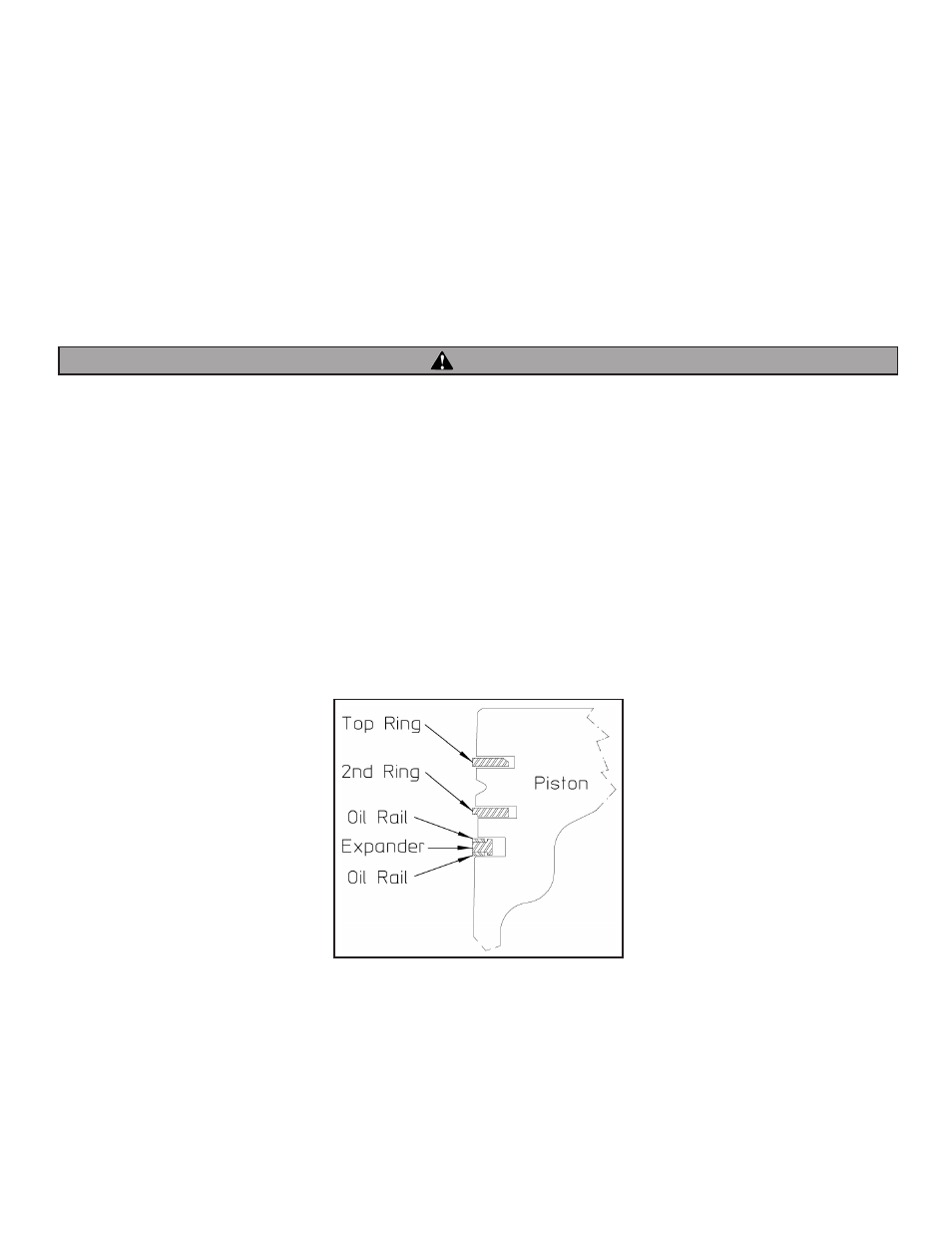

See diagram below for the order of piston rings assembled on the piston.

WARNING