S&S Cycle IST Ignition System for S&S V-Series Engines with Flywheel Machined for Crank Trigger User Manual

Page 11

Overview of check engine light operation.

Initial start sequence.

The check engine light will flash in one of the three ways listed below each time the key is turned on, and the off/run switch is set to run.

• If no faults are detected, the IST ignition will turn the check engine light on for 4 seconds, then off.

• If a fault is present at that time, the check engine light will turn on for four seconds, then turn off for four seconds, then turn on

continuously.

• If a fault has occurred and been corrected within the past 50 key on/off cycles, the check engine light will turn on for four seconds, then

off for four seconds, then on for eight seconds, then off.

• When a fault is detected while the motorcycle is running, a code is stored in memory, and the check engine light comes on

continuously.

Retrieving and displaying codes using the Check Engine light.

a. Turn key and off/run switch to off.

b. Remove seat or side cover to expose the OEM datalink connector, located near the ignition module.

c. Remove rubber plug from OEM datalink connector.

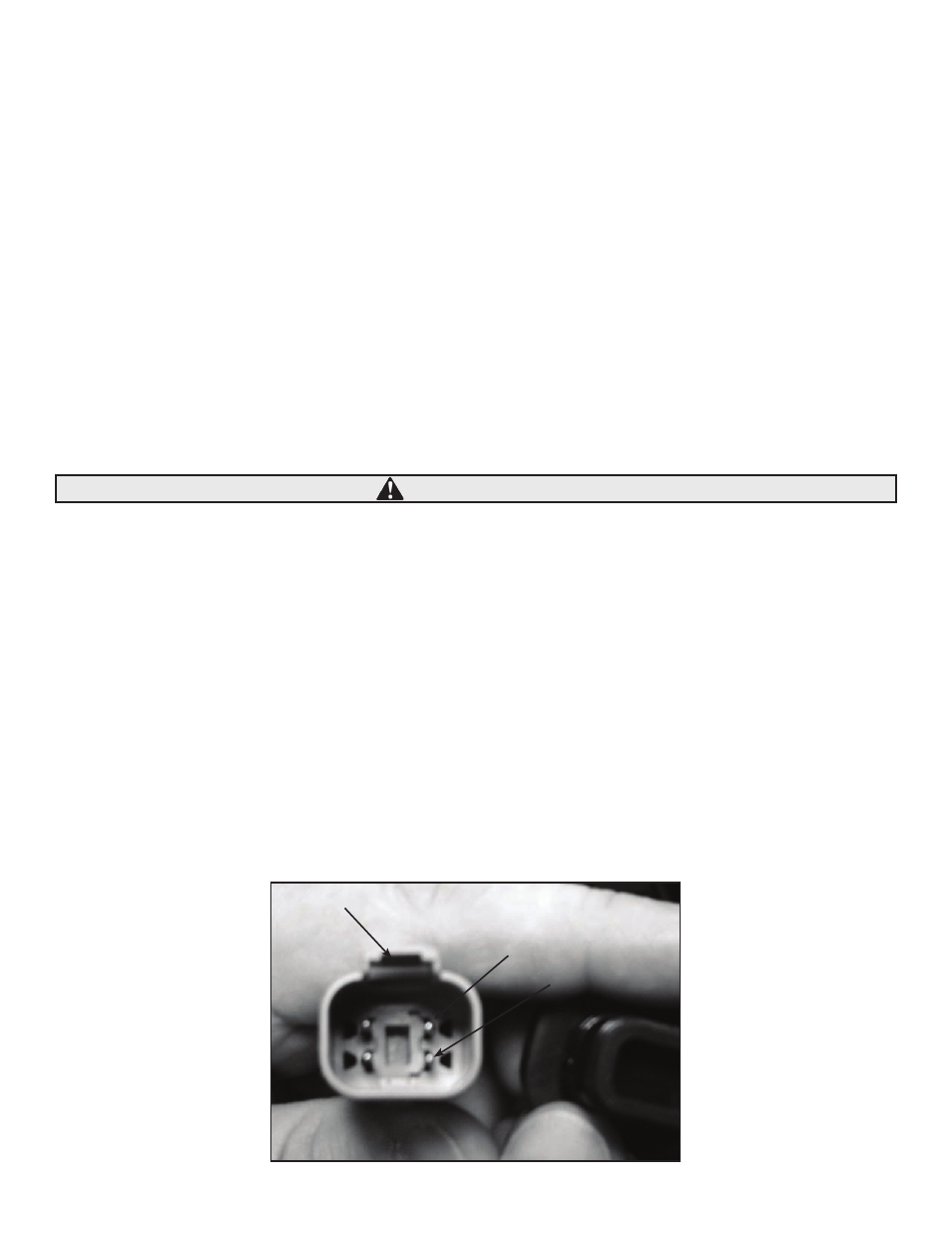

d. Connect pins 1 and 2 of the datalink connector with a jumper wire. Pins have to remain jumpered together during the code retrieval

process.

See Picture 12, below, for pin locations. Do not cross any other pins except pins 1 & 2.

e. Turn key to on Set off/run switch to run, but do not start engine.

f. The check engine light will flash through its initial start sequence, as described above.

g. After the initial sequence of flashes, stored trouble codes will then be sent out as a series of flashes. Trouble codes are stored as two digit

numbers. The first digit of the trouble code is equal to the number of times the light flashes. There is then a 1.2 second pause, then the

second digit of the trouble code is flashed, the second digit being equal to the number of times the light flashes. After three seconds, if

additional codes are stored, they will flash in the same manner as the first, until all codes have been displayed, then the sequence will

repeat continuously. If only one code is stored, it will repeat continuously.

EXAMPLE: After flashing the initial start sequence (as described above) there will be a pause, then flash, flash, flash, flash, (1.2 second

pause) flash. (3 second pause) sequence repeats. This indicates code 41, meaning there is a problem with the crank position sensor.

NOTE: See chart for definitions of fault codes supported by the S&S® ignition module.

h. After retrieving codes, turn ignition key and run switch to off.

i. Remove jumper wire and replace datalink connector plug.

11

Picture 12

Note position of connector lock

Pin 1

Pin 2

CAUTION