S&S Cycle Pistons User Manual

Page 4

4

Failure to remove burrs may cause engine damage.

Incorrect installation of rings may result in poor performance, excessive oil consumption or engine damage.

3- For ring kits in which section #2 above does not apply, compression rings may be of plain cast iron type, chrome faced cast iron type, moly

faced cast type or chrome type.

A- The most common combinations are:

1- Two chrome faced cast rings

2- One chrome faced cast ring & one plain cast ring.

3- One moly faced cast ring & one plain cast ring.

B-

Install as follows:

1- Chrome faced or moly faced ring always goes in top groove

2- Plain cast ring usually goes in second groove. Plain cast type is usually a reverse torsion ring distinguished by an inside diameter bevel

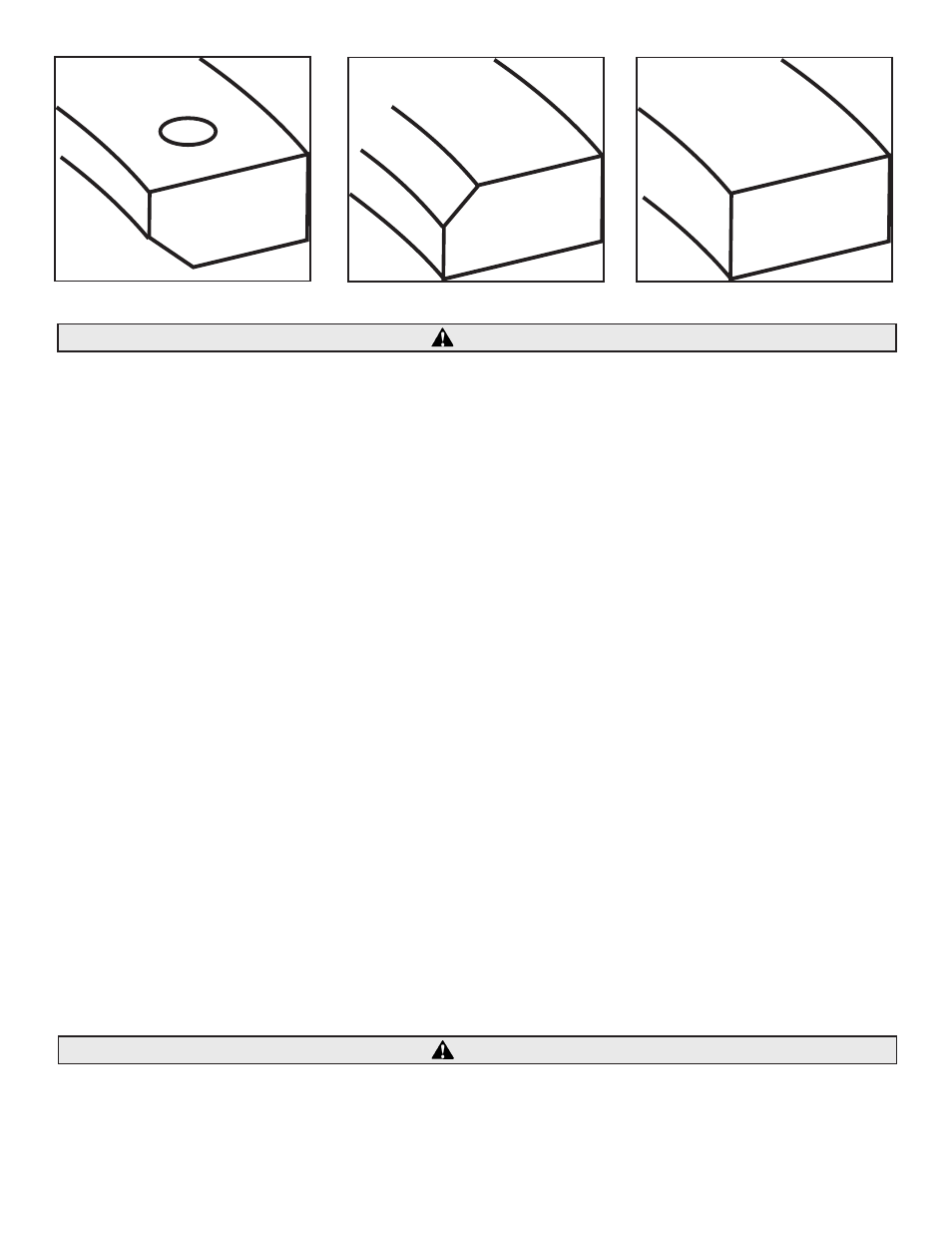

on one side of ring and a "dot" or oversize mark on other side. See Figure 1 above. If two cast iron compression rings are supplied in a

set, check to see if one is reverse torsion style ring with dot and bevel. Reverse torsion style ring always goes in second groove with dot

up if present.

C- The following rules apply to compression ring identification and placement. Rules are listed in order of priority. In other words, if both

Rule #2 and Rule #4 apply, for example, Rule #2 will be followed and Rule #4 ignored.

1- Chrome or moly ring goes in top groove.

2- Cast iron regular or reverse torsion ring goes in second groove.

3- Any identifying "pip" marks, dots or oversize marks go to top of piston.

4- Ring with one dot goes in top groove, ring with two dots goes in second groove.

5- If both rings are identical and have one dot or two dots, either ring can go in either groove.

6- If ring has dot and inside diameter bevel, dot goes to top of piston. See Figure 1above.

7- If ring has no dot but does have inside diameter bevel, bevel goes to top of piston. See Figure 2 above.

8- If ring has no dots and no bevel, it can go either way. See Figure 3 above.

4- Ring Gap Measurements

A- Compression ring end gap on big twins with 31⁄2" bore is .014" to .022".

B- End gap on all other compression rings is .016" to .024".

C- Oil ring rail end gap on big twins with 31⁄2" bore is .015" to .035".

D- Oil ring rail end gap on all others is .015" to .035".

E- Compression ring end gap on big twins with 41⁄8" bore is .017" to .025".

F- Oil ring rail end gap on big twins with 41⁄8" bore is .015" to .035".

NOTE: In certain instances, the next oversize ring set may be supplied with pistons, for example + .060" oversize rings with +.050" pistons. In this case end

gaps must be measured and rings filed as necessary. Ends must then be carefully deburred.

Failure to deburr rings may result in engine damage.

Piston Series 92-1210, 92-1550, 92-1556, and 92-1560 have a ring support rail that needs to be installed before any other rings are

installed.

CAUTION

Figure 1

Figure 2

Figure 3

CAUTION