S&S Cycle Pistons User Manual

Page 2

2

GENERAL INFORMATION

1- For maximum piston and ring life, fit pistons using close fit dimensions. Close fit requires absolute adherence to new engine break-in as

described on page 7.

2- For immediate drag strip use, fit pistons using loose fit dimensions. Break in rings and pistons with 50 easy miles if possible. Piston and ring life

will be reduced with loose fit dimensions.

3- Measure all pistons at widest point across thrust face, perpendicular to wristpin hole. Several measurements should be taken to locate widest

point. Typically, this will be at bottom of piston skirt for pre-1984 big twins, and approximately 1⁄2" below level of wristpin hole in pistons for

Harley-Davidson® Evolution® and Twin Cam 88® engines. If pre-1984 piston is notched for placement in rear cylinder, use measurement directly

above notch for skirt measurement.

4- S&S® recommends #220-#280 grit stone for final honing of stock bore and Sidewinder®, S&S T124 and S&S big bore cylinders. #320 grit stone is

recommended for engines using S&S 92-4500, 92-4510, or 92-4520 pistons.

5- Follow procedure recommended in Harley-Davidson® service manual for boring and honing stock bore big twin and Twin Cam 88® cylinders.

Follow instructions included with S&S Cylinder Torque Plate Kit when boring and honing S&S 35⁄8" or 4", 41⁄8" bore cylinders. Torque plates must

be used to simulate compressive stress in an assembled engine. Cylinders will distort if torque plates are not used.

Failure to follow instructions and perform required clearancing, installation and/or break-in procedures may result in damage to pistons

and/or other engine components not covered under warranty.

Piston

CAUTION

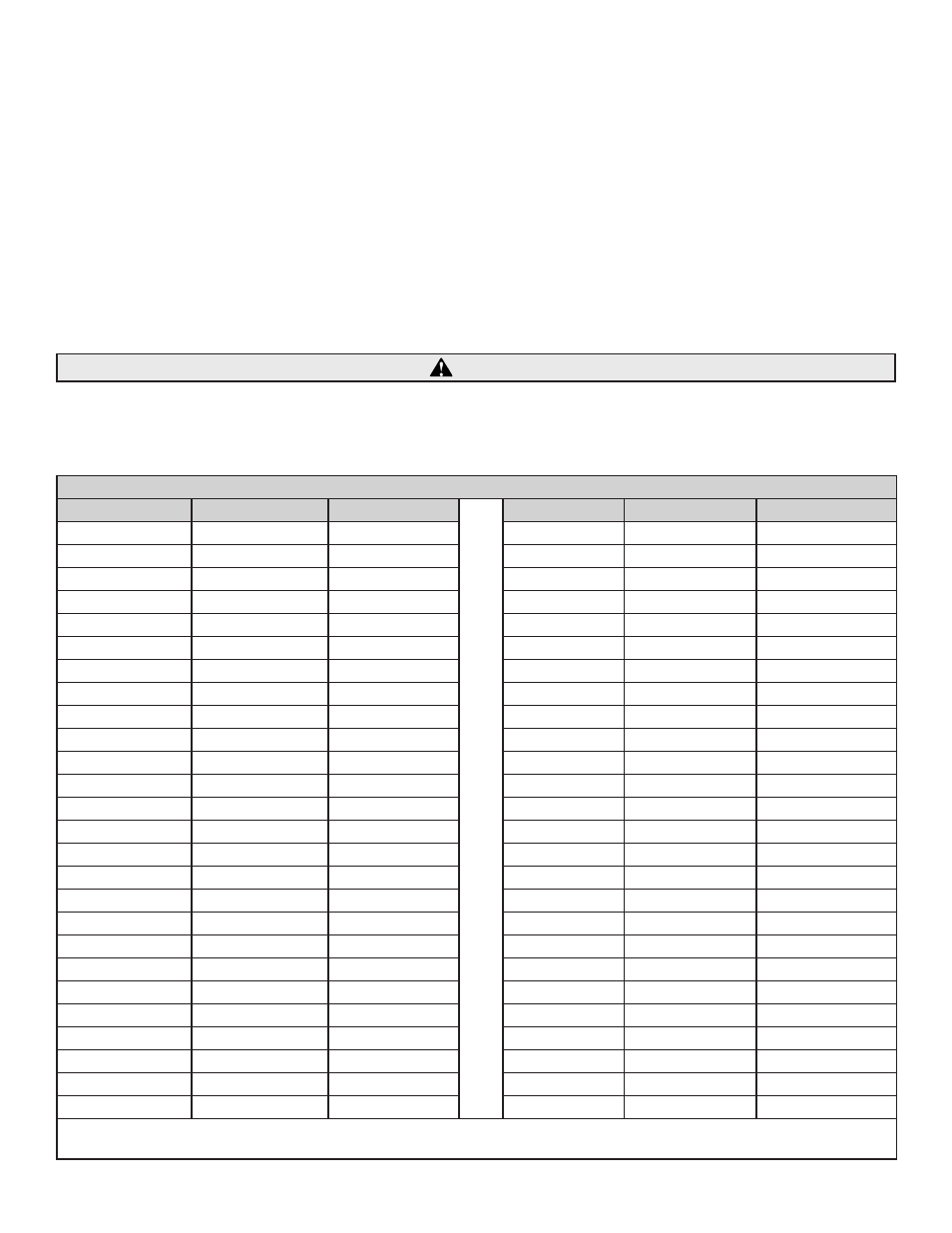

Piston Fitment Chart

Piston Series

Close Fit

Loose Fit

Piston Series

Close Fit

Loose Fit

92-1060

.0023" to .0025"

.0035" to .0045"

92-1900

.002" to .0025"

.003" to .004"

92-1080

.0023" to .0025"

.0035" to .0045"

92-1910

.002" to .0025"

.003" to .004"

92-1100

.0023" to .0025"

.0035" to .0045"

92-1930

.002" to .0025"

.003" to .004"

92-1110

.0023" to .0025"

.0035" to .0045"

92-1940

.002" to .0025"

.003" to .004"

92-1120

.0023" to .0025"

.0035" to .0045"

92-2000

.002" to .0025"

.003" to .004"

92-1130

.0023" to .0025"

.0035" to .0045"

92-2010

.002" to .0025"

.003" to .004"

92-1200

.002" to .0025"

.0032" to .0045"

92-2020

.002" to .0025"

.003" to .004"

92-1210

.002" to .0025"

.0032" to .0045"

92-2030

.002" to .0025"

.003" to .004"

92-1400

.002" to .0025"

.0032" to .0045"

92-2040

.002" to .0025"

.003" to .004"

92-1410

.002" to .0025"

.0032" to .0045"

92-2050

.002" to .0025"

.003" to .004"

92-1420

.002" to .0025"

.0032" to .0045"

92-2420

.0008" to .0013"

.002" to .0025"

92-1430

.002" to .0025"

.0032" to .0045"

92-2440

.0008" to .0013"

.002" to .0025"

92-1436

.002" to .0025"

.0032" to .0045"

92-2460

.0008" to .0013"

.002" to .0025"

92-1550

.002" to .0025"

.0032" to .0045"

92-2500

.002" to .0025"

.003" to .0035"

92-1556

.002" to .0025"

.0032" to .0045"

92-2510

.002" to .0025"

.003" to .0035"

92-1560

.002" to .0025"

.0032" to .0045"

92-2600

.002" to .0025"

.003" to .0035"

92-1620*

.002" to .003"

.0035" to .004"

92-2610

.002" to .0025"

.003" to .0035"

92-1630***

.0015" to .002"

.0025" to .0035"

92-2700***

.0015" to .002"

.0025" to .0035"

92-1630*

.002" to .003"

.0035" to .004"

92-2720*

.002" to .003"

.0035" to .004"

92-1640***

.0015" to .002"

.0025" to .0035"

92-2730*

.002" to .003"

.0035" to .004"

92-1640*

.002" to .003"

.0035" to .004"

92-2800***

.0025" to .003"

.0045" to .0055"

92-1800***

.0025" to .003"

.0045" to .0055"

92-2800*

.0035" to .004"

.005" to .006"

92-1800*

.0035" to .004"

.005" to .006"

92-2900*

.0035" to .004"

.0035" to .004"

92-1830*

.0035" to .004"

.005" to .006"

92-3700

.003" to .0035"

.0045" to .0055"

92-1840*

.0035" to .004"

.005" to .006"

*** - With Slotted Oil Ring Groove * - With holed Oil Ring Groove