S&S Cycle Big Bore Kits 97 & 106 for 1999–06 & 2007–Up Big Twins User Manual

Page 3

3

7- Ensure that ring end gaps are square.

8- Remove sharp edges and burrs.

9- Recheck gap measurement and adjust as necessary.

10- Repeat procedure with the other rings.

B- Piston Ring Installation

Order of installation

1- Oil ring expander (ends must face up as shown in Picture 3, above)

2- Oil ring rails

3- 2nd ring

4- Top ring

1- Install the oil ring expander to the bottom groove of the piston.

The expander ring has a gold finish. Make sure the end of the

expander ring is butted together and not overlapping (Picture

3, above). If the tips are overlapped, excessive oil consumption

will occur. Orient the expander gap such that it can be viewed as

it enters the cylinder. See Picture 5c, bottom right.

2- Install oil rails. The oil rails are the thinnest of all the rings. Either

side can be placed up. Use a ring expander to install the rails into

the groove. Install one rail above the expander, and one below.

Orient the gaps according to Picture 5a, top right.

3- Install the 2nd ring with the dot facing up (see Picture 4, below).

The 2nd ring has a dull black finish and is the thickest of all the

rings. Use an expander to install the ring to the 2nd groove in the

piston. Orient the gap according to Picture 5a, top right.

4- The top ring must be installed with the dot or letter facing up.

If there is no marking, the top ring can be installed with either

face up. The top ring has a chrome edge and is thicker than the

oil rails. Use a ring expander tool to install the ring to the top

groove. Orient the gap according to Picture 5a, top right.

C- Piston Installation

NOTES

•

Pistons are identical and can be installed in either cylinder. Each piston

is stamped “FWD" or has an arrow which must point toward the front of

the engine when assembled.

•

Check piston pin to connecting rod bushing clearance. Clearance should

be between 0.0007" and 0.0012". Bushing should be replaced if clearance

exceeds 0.002".

1- Place rubber tubing over the cylinder studs to prevent damage

to the pistons and rings during assembly.

2- Place a clean sheet of plastic over the crankcase openings to

prevent anything from dropping into the crankcase.

3- Install one of the piston pin clips into each of the pistons. Make

sure the piston pin clip opening is facing up when installed.

4- Lightly oil the piston pin, piston pin bore and upper connecting

rod bushing with clean 20W-50 oil or assembly lube.

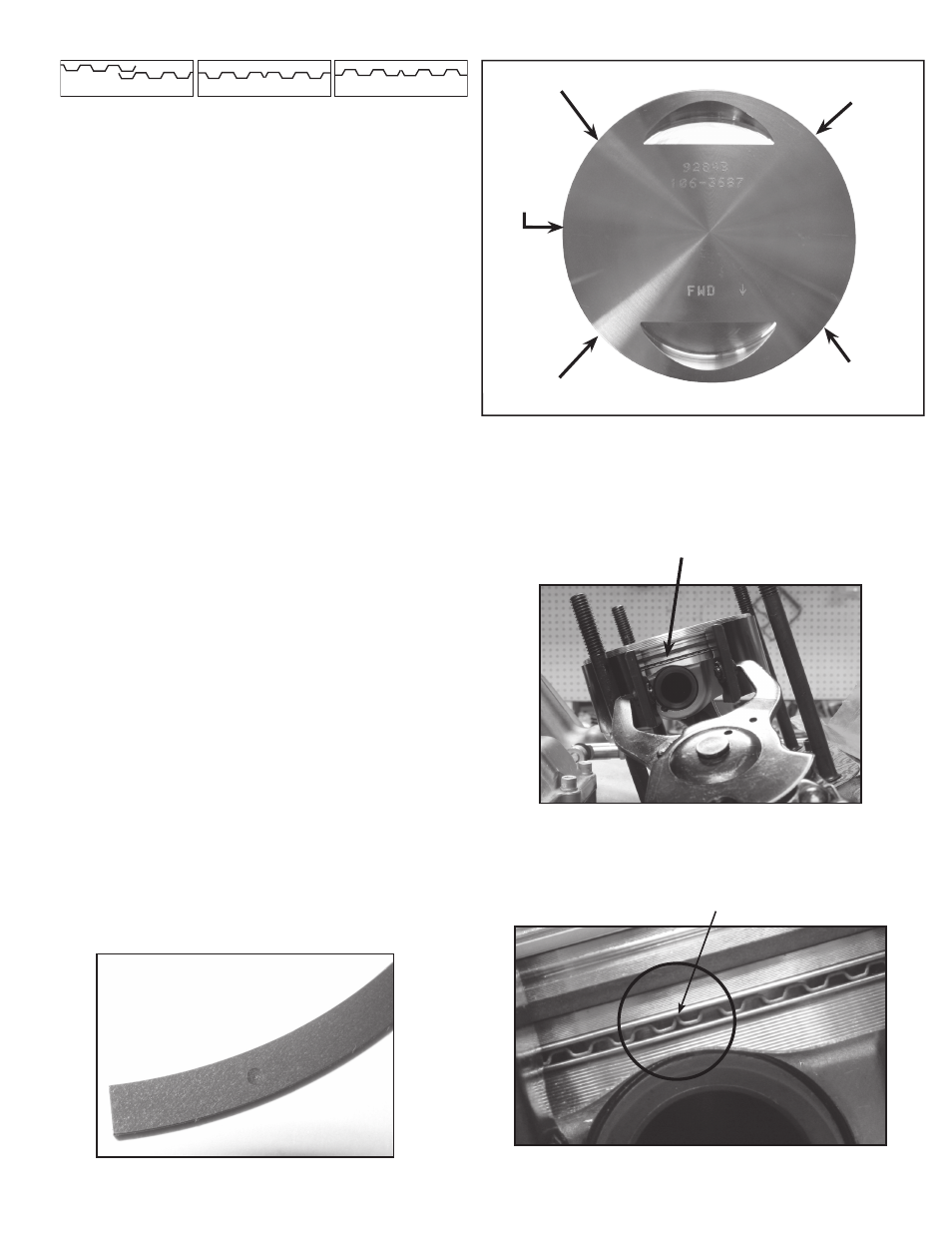

Picture 3

Incorrect orientation

Incorrect overlap

Correctly butted tips facing up

Picture 4

Picture 5a

Top Ring Gap

Expander

Ring Gap

Top Oil Rail Gap

Second Ring Gap

Bottom Oil Rail Gap

C

AM

SI

D

E

DR

IV

E S

IDE

Picture 5c

Picture 5b

Expander ring gap