S&S Cycle Big Bore Kits 97 & 106 for 1999–06 & 2007–Up Big Twins User Manual

Page 2

2

INSTALLATION AND REASSEMBLY

A- Setting Ring End Gaps

NOTES

•

Important! The gap of the second ring should be larger than the top ring;

this will help keep the top ring seated for improved performance.

•

Each ring should be fitted to the particular cylinder in which they will be

installed.

•

Oil rails can be installed without adjusting the end gap. The minimum

gap should be 0.010"

•

Never alter the end gap of the oil expander ring.

•

Always install the ends of the expander facing up as shown in Picture 3,

top of next page.

1- Thoroughly wash cylinders with hot soapy water, then wash with

brake cleaner and wipe with a clean white towel. Repeat until

towel does not show evidence of debris and apply a light coat

of oil immediately.

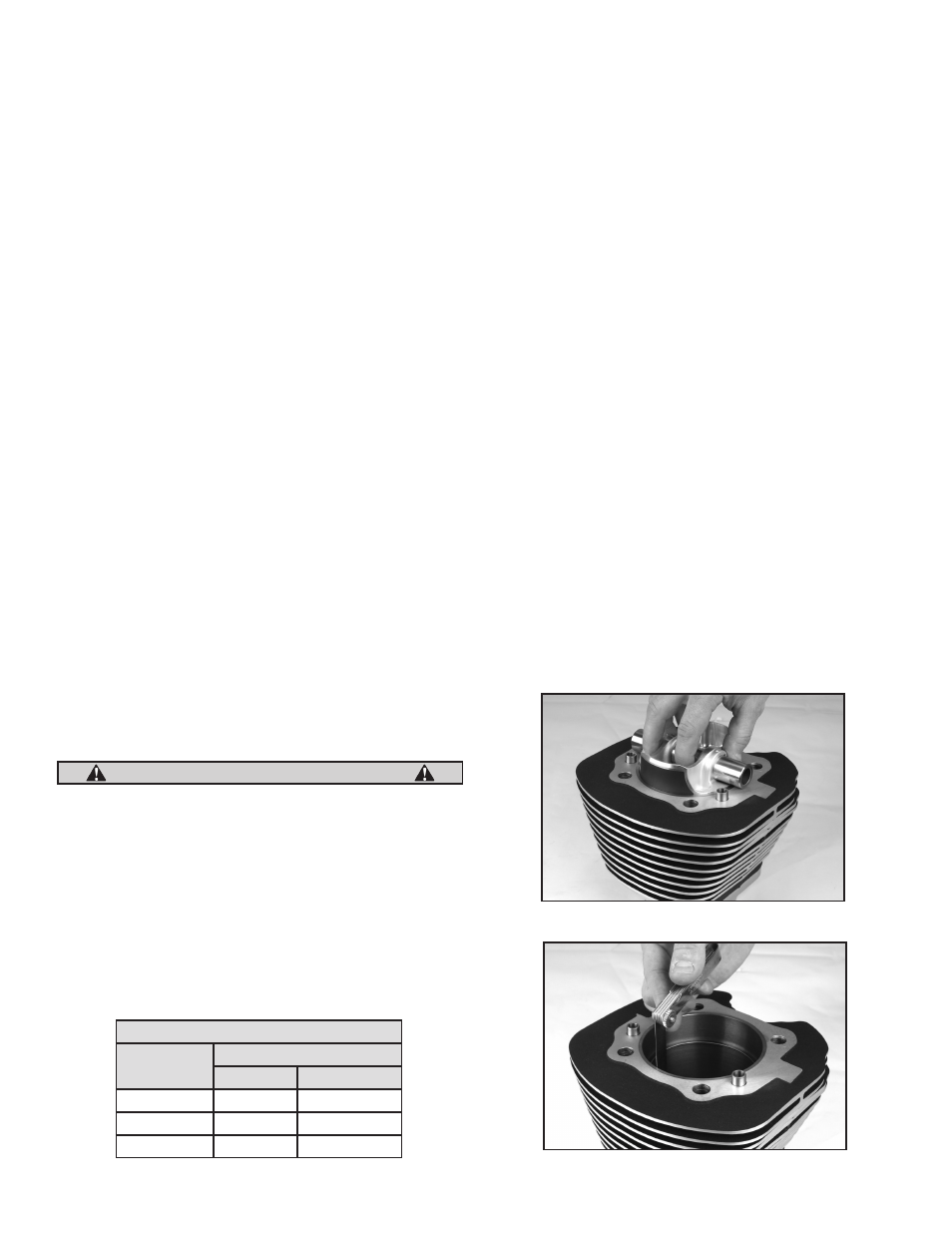

2- Check the ring end gap by placing the ring into the cylinder. Use

a piston or caliper to ensure that the ring is placed squarely in

the bore.

3- Measure the ring end gap with a feeler gauge.

4- See table for proper end gap measurement. If adjustment to the

gap must be made, use a proper ring end gap filing tool.

5- Always file from the ring face towards the inside diameter to

avoid damaging the face coating.

6- Remove material from only one end of the ring.

GENERAL INFORMATION

•

Thoroughly read and understand all the instructions before

starting installation.

•

S&S 106" big bore kits contain 3.927" bore pistons with 1.090" deck

height. These kits are intended for stock stroke (4.375") 2007–up

big twin engines.

•

S&S 97" big bore kits contain 3.927" bore pistons with 1.270" deck

height. These kits are intended for stock stroke (4.000") 1999–’06

big twin engines.

•

Pistons are the same for the front and rear cylinders and can be

used with either cylinder.

•

The 3.927" piston is marked with an arrow that should point to the

front of the engine when installed.

•

The pistons are machined during manufacturing, to provide the

correct running clearance when cylinders are bored to nominal

size of 3.927". In other words the clearance it built into the

piston diameter. If you wish to confirm piston diameter be sure

to measure the piston only at the micrometer windows on the

front and rear skirts of the piston. Measuring the piston in areas

with non-stick coating applied will result in incorrect readings.

Cylinder measurements must be taken with the cylinder in torque

plates with bolts tightened at correct torque value to simulate

conditions in an assembled engine.

•

In all cases it is the engine builder’s responsibility to confirm

proper clearances when assembling an engine. This is especially

critical with performance components such as larger valve, high

performance heads and high lift camshafts.

•

In addition to clearances mentioned, 0.060" valve to piston

clearance must be confirmed.

CAUTION

Failure to follow instructions and perform required clearancing,

installation and/or break-in procedures may result in damage

to pistons and or other engine components not covered under

warranty. The proper break-in procedure is in Section 4 of these

instructions.

DISASSEMBLY

Refer to the Harley-Davidson® manual for your specific motorcycle for

the correct disassembly procedure.

The engine should be disassembled to the short block i.e. induction

system, exhaust system, cylinder heads, cylinders, and pistons should

be removed.

KIT CONTENTS

(2) 3.927" pistons (front and rear pistons are the

same)

(2) 0.927" piston pins

(4) Piston pin clips

(2) Ring packs which include the top, second,

oil rail, and expander rings

(2) Cylinders

(2) MLS (Multi Layer Steel) head gaskets

(2) Cylinder base O-rings

(2) Cylinder base dowel O-rings

(2) Exhaust gaskets

SPECIAL TOOL REQUIREMENTS

• Harley-Davidson® service manual for the

specific model you are working on

• Piston C-clip installer

• Piston ring compressor

• Piston ring expander

• Piston ring end gap filing tool

• Digital or dial calipers

• Feeler gauge

INSTRUCTION CONTENTS

General Information

Disassembly

Installation and Reassembly

A- Setting Ring End-Gap

B- Piston Ring Installation

C- Piston Installation

D- Cylinder Installation

E- Cylinder Head Installation

F- Final Assembly

E- Break-in Procedure

Picture 1

Picture 2

Suggested ring end gaps

Ring

Ring Gap Tolerance (inches)

Min

Max

Top

0.016

0.022

2nd

0.016

0.026

Oil ring rails

0.010

0.050