S&S Cycle Chain Drive Camshaft for 2007-Up Big Twin and 2006-Up Harley-Davidson Dyna User Manual

Page 3

3

SECURING THE MOTORCYCLE

Motorcycle must be adequately secured during the cam change operation! Use of tie down straps on both sides of the motorcycle is

recommended.

1- Place motorcycle on a suitable repair stand so that the motorcycle is stable and secure with the rear tire elevated.

2- Disconnect the negative terminal of the battery to eliminate potential sparks and inadvertent engagement of the starter while working on the

motorcycle.

3- Place motorcycle in top gear. Remove spark plugs. These steps are necessary so that the rear tire can be used to rotate the engine to correctly

align the cam timing marks during installation, and align the oil pump during reassembly.

DISASSEMBLY

Cutting the pushrods with a saw may result in metal chips entering the engine and causing extensive damage which will not be covered

under warranty.

Cutting pushrods without relieving valve spring force on the pushrods may result in injury.

1- Remove pushrods.

a- Remove pushrod cover clips with a small screwdriver and compress pushrod covers to expose pushrods. Lift rear tire of motorcycle with a

suitable jack. Rotate the engine until one of the cylinders is on “top dead center compression stroke” (TDCC). TDCC can be found by rolling

the rear tire forward while watching or feeling the pushrods move through their travel. When BOTH pushrods are at the lowest point of

their travel and the piston for that cylinder is at TDC, the engine is at TDCC. Rotate the pushrods to ensure there is no load on them. If the

pushrods will not rotate freely by hand, either the engine is not on TDCC, or the lifters need to bleed down. It may be necessary to let the

lifters bleed down for a few minutes before the pushrods will rotate freely.

b- If S&S adjustable pushrods will be used for re-assembly, the stock pushrods may be cut to remove them at this time. When cutting pushrods,

S&S recommends a bolt cutter be used as it is the cleanest method. Be sure to only cut the pushrods that are not loaded and rotate freely

by hand.

c- If stock one piece pushrods are to be re-used, remove the gas tank and rocker box covers. Remove the rocker arm support by first removing

the two smaller bolts which hold the breather cover in place. Next break loose the four bolts holding the rocker arm support plate in place

with an alternating pattern. Remove the four rocker arm support plate bolts, and then the rocker arm support assembly. The pushrods

may now be removed by sliding them up into the head slightly and then pulling the bottom of the pushrod towards you. Mark the original

pushrod location as it is removed to ensure it is replaced in its original position. The intake pushrod is shorter than the exhaust pushrod.

Interchanging the intake and exhaust pushrods upon reassembly, will cause the intake valve to stay open on the compression stroke and

the engine will not run.

d- Rotate the engine so the other cylinder is on TDC compression and repeat the above procedure.

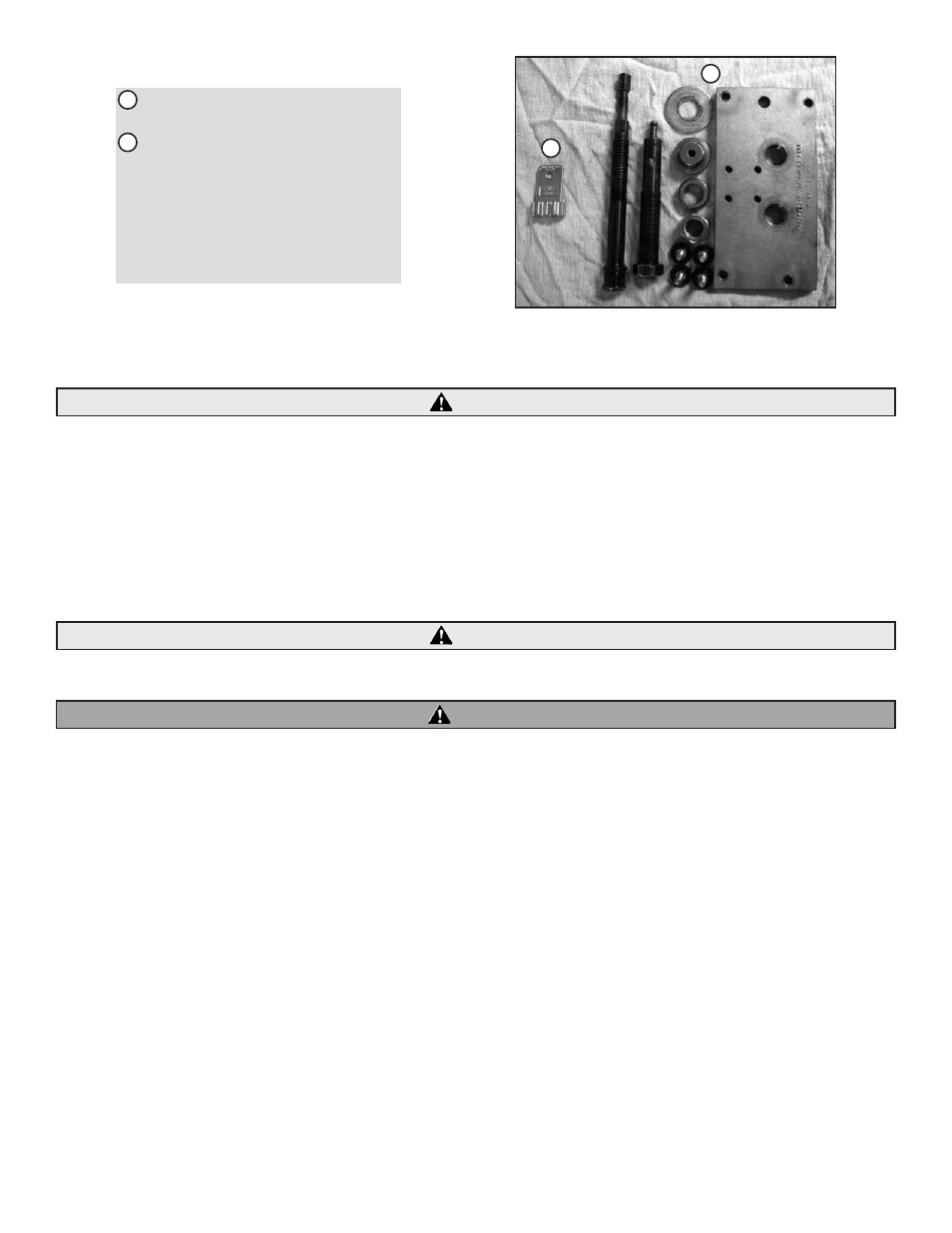

Picture 1

CAUTION

CAUTION

1- Crankshaft/Camshaft Sprocket Locking Tool,

H-D® Part Number: 47941

2- Camshaft Needle Bearing Remover/Installer,

H-D Part Number: 42325

All reference to Harley-Davidson part numbers

•

is for identification purposes only. We in no way

are implying that any of S&S Cycle’s products

are original equipment parts or that they

are equivalent to the corresponding Harley-

Davidson part numbers.

2

1

1

2

WARNING