Working instructions, Sieving aids quantities of material to be sieved, Overview table – Retsch AS 200 tap 30.025.0001 User Manual

Page 19: Quantities of material to be sieved, Sieving aids

08.01.2008

Retsch GmbH

19

Doc.Nr. D 98.025.9999

Working Instructions

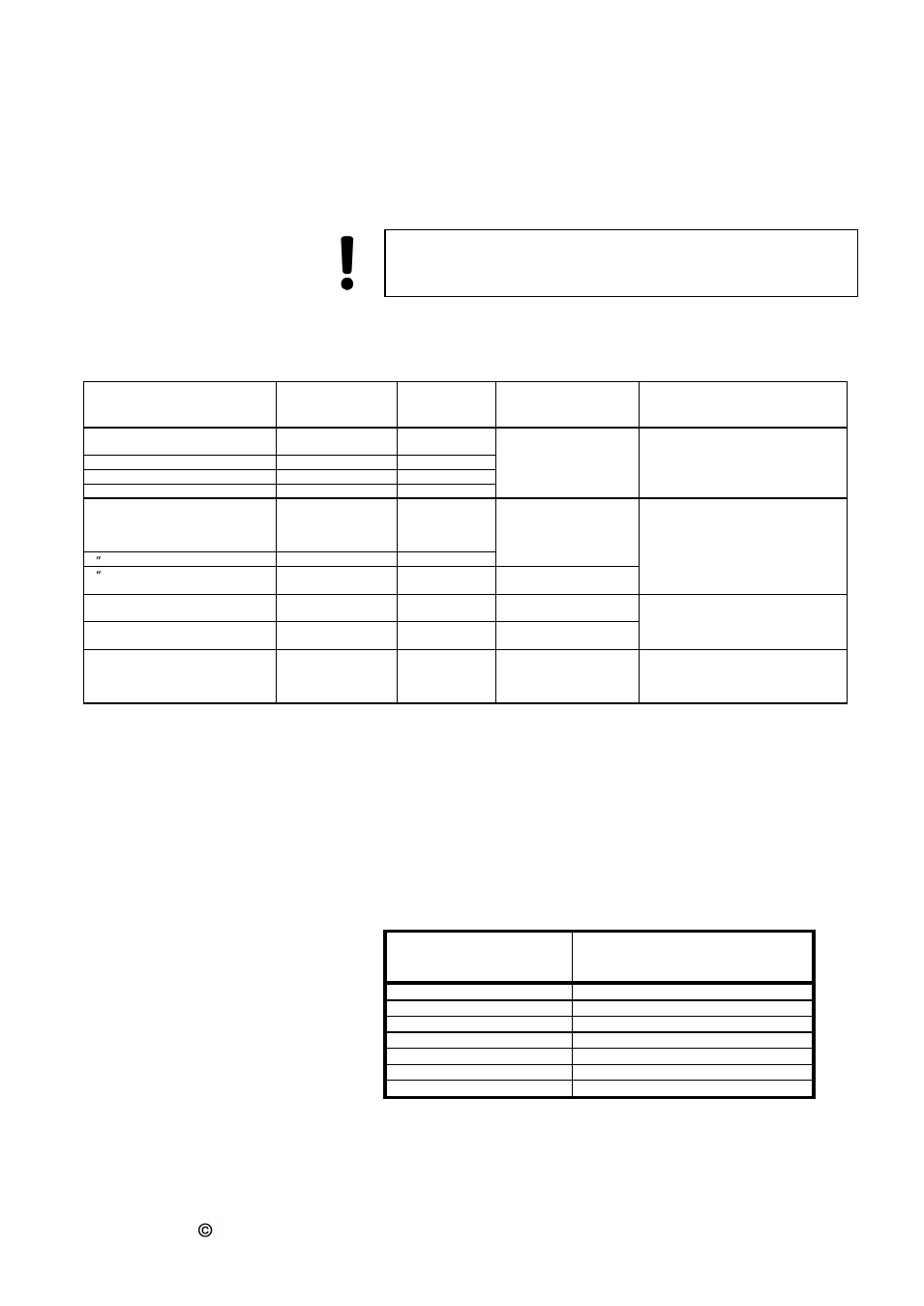

Sieving aids

For materials which are difficult to separate we recommend the ad-

ditional use of sieving aids in the individual sieve fractions. For this

purpose balls of agate, rubber, porcelain or nylon brushes and

Vulkollan cubes can be used, depending on the mesh size of the

sieve and the preselected oscillation intensity. See also the table

below.

Make sure that the sieve fabric is not excessively expanded

through overloading with sieving aids since this will impair the

precision of your analytical sieves.

For recommended quantities of sieving material see the section

„Quantities of material to be sieved“

Overview table

Sieving aids

Quantity per

sieve or sieved

material

Supplier

Field of application

Caution!!

Cubes of Vulkollan

5, 12x12

RETSCH, Haan

With use of plane siev-

ing machines

Brushes

3

RETSCH, Haan

Plastic rings

3, various dia.

Small brushes

With hand sieving

Highly dispersed silica

(Aerosil)

0.5 to 2%

Degussa, Ffm

With fine, sticky,greasy

sieved materials and

materials which are

electrostatically charged

Before adding check usability and

compatiblity

- - Aluminium oxide

0.5 to 1%

Degussa, Ffm

- - Talcum

With crude rubber and

rubber powder

Drying

With very wet / very

damp sieved material

Pass dry warm air through the

set of sieves

With hygroscopic sieved

materials

TAP function

With fine, easily sticking

sieved materials which

fall through the meshes

only with difficulty

A TAP function is built into the Tap

Sieving Machine AS 200 tap, which

can be switched off as required.

Quantities of material to be sieved

A set of sieves required for sieve analysis is made up of a number

of analytical sieves arranged one on top of the other with increas-

ing mesh size.

In order to guarantee quick fractioning with an exact result the

quantity of material to be sieved must be adapted to the sieve di-

ameter and the nominal diameter of the openings.

Guide values for this are given in the respective standard specifi-

cations for sieve analysis, e.g. according to DIN 22019/1 the fol-

lowing maximum added quantities are recommended:

Nominal diameter of

sieve openings

Material quantities in dm3 for

200mm diameter

8

0 . 5 0 0

3 . 1 5

0 . 3 0 0

1

0 . 1 4 0

0 . 5

0 . 1 0 0

0 . 2

0 . 0 6 0

0 . 0 6 3

0 . 0 3 5

0 . 0 2 0

0 . 0 2 0